Maintenance

5. Replace the oil lter every other oil change. Clean

around oil lter and unscrew lter to remove.

Before reinstalling new lter, apply a thin coating

of oil on the surface of the rubber seal. Turn

lter clockwise until rubber seal contacts the lter

adapter then tighten lter an additional 2/3 to

3/4 turn.

6. Clean around oil ll cap and remove cap. Fill to

specied capacity and replace cap.

7. Use oil recommended in engine owner’s manual.

Do Not overll. Start the engine and check for

leaks.

Check Hydraulic Oil Level

Service Interval: Every 40 hours

1. Stop engine and wait for all moving parts to stop.

Engage parking brake.

2. Tilt seat up.

3. Clean area around hydraulic reservoir cap and

remove cap. Oil level should be to the top of the

bafe inside the tank. If not, add oil. Use only

Mobil 1 15W-50 synthetic motor oil. Replace

hydraulic reservoir cap and tighten until snug. Do

Not overtighten.

Note: The bafe is labeled “HOT” and

“COLD”. The oil level varies with the

temperature of the oil. The “HOT” level shows

the level of oil when it is at 225°F (107°C). The

“COLD” level shows the level of the oil when

it is at 75°F (24°C). Fill to the appropriate level

depending upon the temperature of the oil. For

example: If the oil is about 150°F (65°C), ll to

halfway between the “HOT” and “COLD” levels.

If the oil is at room temperature (about 75°F

(24°C)), ll only to the “COLD” level.

Check Auxiliary Hydraulic

Oil Level

Service Interval: As required

Note: Check the auxiliary hydraulic oil level if there

is evidence of a leak or the hydraulic cylinder does

not perform normally.

1. Retract the hydraulic cylinder.

2. Stop engine and wait for all moving parts to stop.

3. Tilt the seat forward.

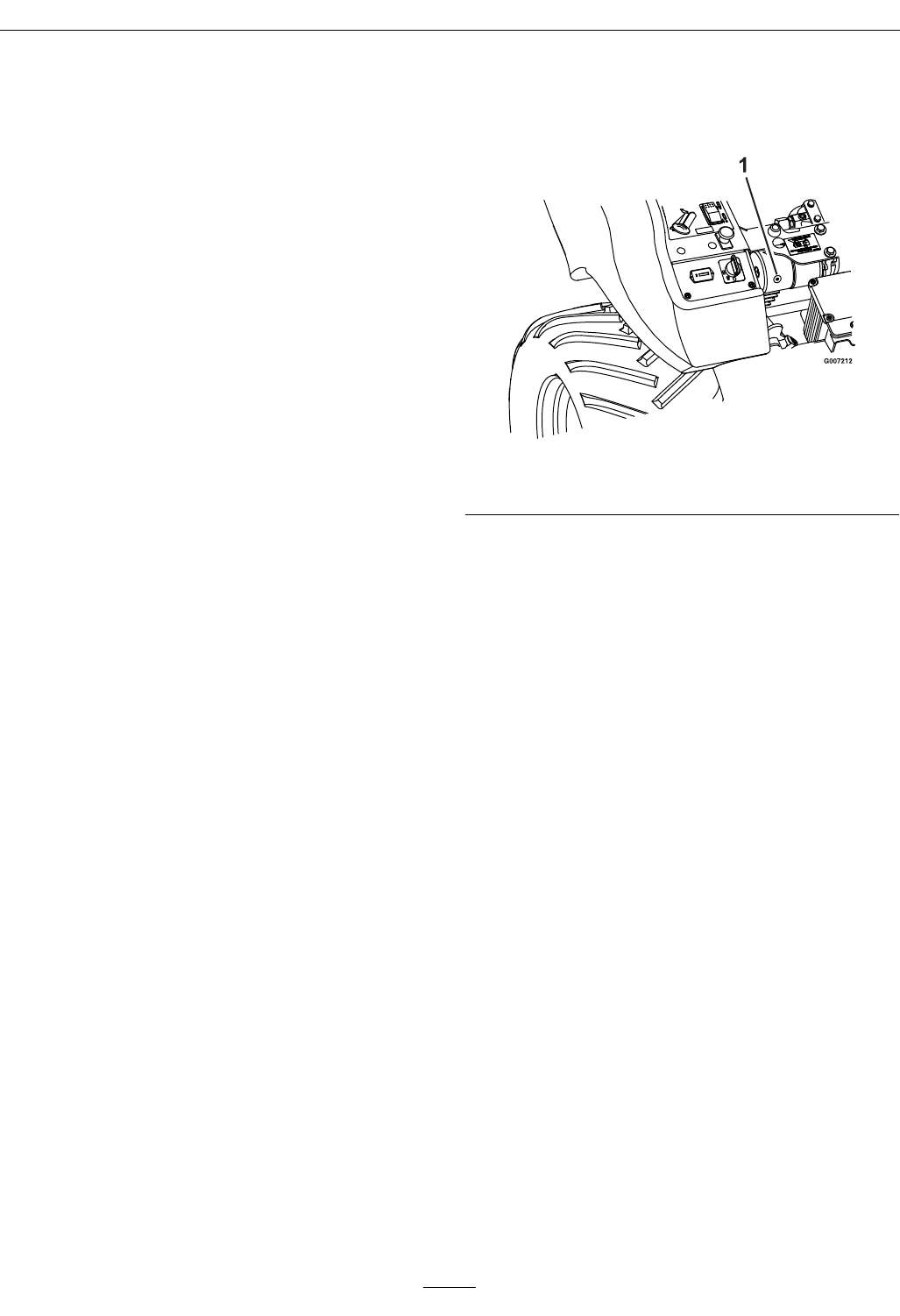

4. Locate the auxiliary hydraulic power unit reservoir

(see Figure 9).

Figure 9

1. Auxiliary hydraulic reservoir plug

5. Clean area around the reservoir plug and remove.

Oil level should be up to the reservoir plug hole.

If not, add oil. Use only Mobil 1 15W-50 synthetic

motor oil. Replace reservoir plug and tighten until

snug. Do Not overtighten.

Check Tire Pressures

Service Interval: Every 40 hours

1. Stop engine, wait for all moving parts to stop, and

remove key. Engage parking brake.

2. Check tire pressure in drive tires.

• For 23HP Kohler Units: The drive tires

should be inated to 13 psi (90 kpa).

• For 27HP Kohler & 31HP Briggs & Stratton

Units: The drive tires should be inated to 9

psi (62 kpa).

3. The rear caster tire(s) is semi-pneumatic and does

not need to be inated.

Note: Do Not add any type of tire liner or foam

ll material to the tires. Excessive loads created by

foam lled tires may cause failures to the hydro drive

system, frame, and other components. Foam lling

tires will void the warranty.

27