2468CB & 2468CD Dual Power Supply Version Hydrastep 2468CB and 2468CD Manual

2-24 24685034

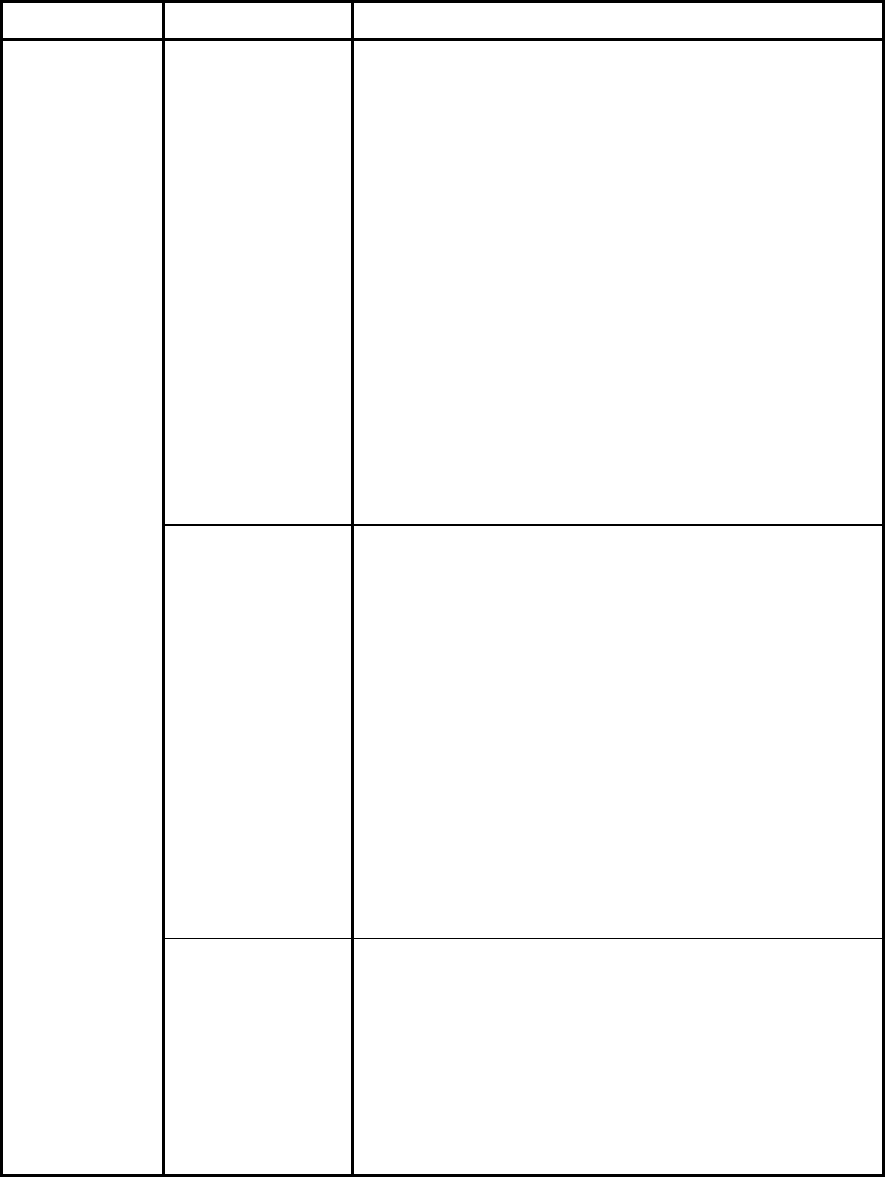

Indication Fault(s) Analysis and Corrective Action

State 1 (contd.)

Incorrect wiring,

broken connection

or damaged cable

assembly

Affected

electrode(s)

alternate between

water and steam.

Check ac voltage on electrodes with a true r.m.s.

voltmeter. A voltage of less than 0.1V ac indicates a fault

condition.

If wiring to the electrode is correct and the electrode

gives a voltage reading of greater than 0.1V ac and a

fault is still indicated, carry out the following procedure:

1. Remove both conductors from the suspect electrode.

With the conductors isolated from each other, the

level display should show the electrode as

alternating between water and steam (green and

red).

2. With the conductors touching each other, the level

display should show electrode as being in steam.

The above procedure checks the electrode wiring. If the

display does not show the correct results, then check for

a break in either of the suspect electrode conductors.

Carry out repair to any faulty connection or substitute a

new conductor or cable assembly in place of the

defective item.

Dirt on electrode

Affected

electrode(s)

alternate between

water and steam.

If the wiring checks carried out as described above have

not located a fault, then dirt on an electrode insulator may

be the cause of the problem giving an effective short-

circuit to ground.

Check the electrodes for dirt over the external insulator

and clean with a cloth as required.

Checking for dirt on the internal insulator of the electrode

requires the draining of the water column (refer to Part 2

of this manual for the correct procedure).

Once the water column is drained, check the ac voltage

on each electrode using a true r.m.s. voltmeter. Any

electrode showing a voltage of less than 3V ac needs

cleaning or replacement. Electrodes must be removed

from the column for inspection and cleaning.

Note: The electrode insulator can be cleaned using a

clean cloth

Internal fault If the wiring checks carried out as described above have

not located a fault, then it is possible an internal fault

exists.

1. Disconnect the electrode cable sockets from the

input board.

2. Make up four 10-way sockets (six or eight sockets

required for systems with more than 16 points) with

wire links connecting the following pins on each

socket; 1-2, 4-5, 6-7, 9-10.

Table 2.3 - Fault analysis/corrective action chart (continued)