13

Po w e r Bl o w e r

oP e r a t o r 's Ma n u a l

G

PB-500T

WARNING

Never perform maintenance or assembly procedures with engine

running or serious personal injury may result.

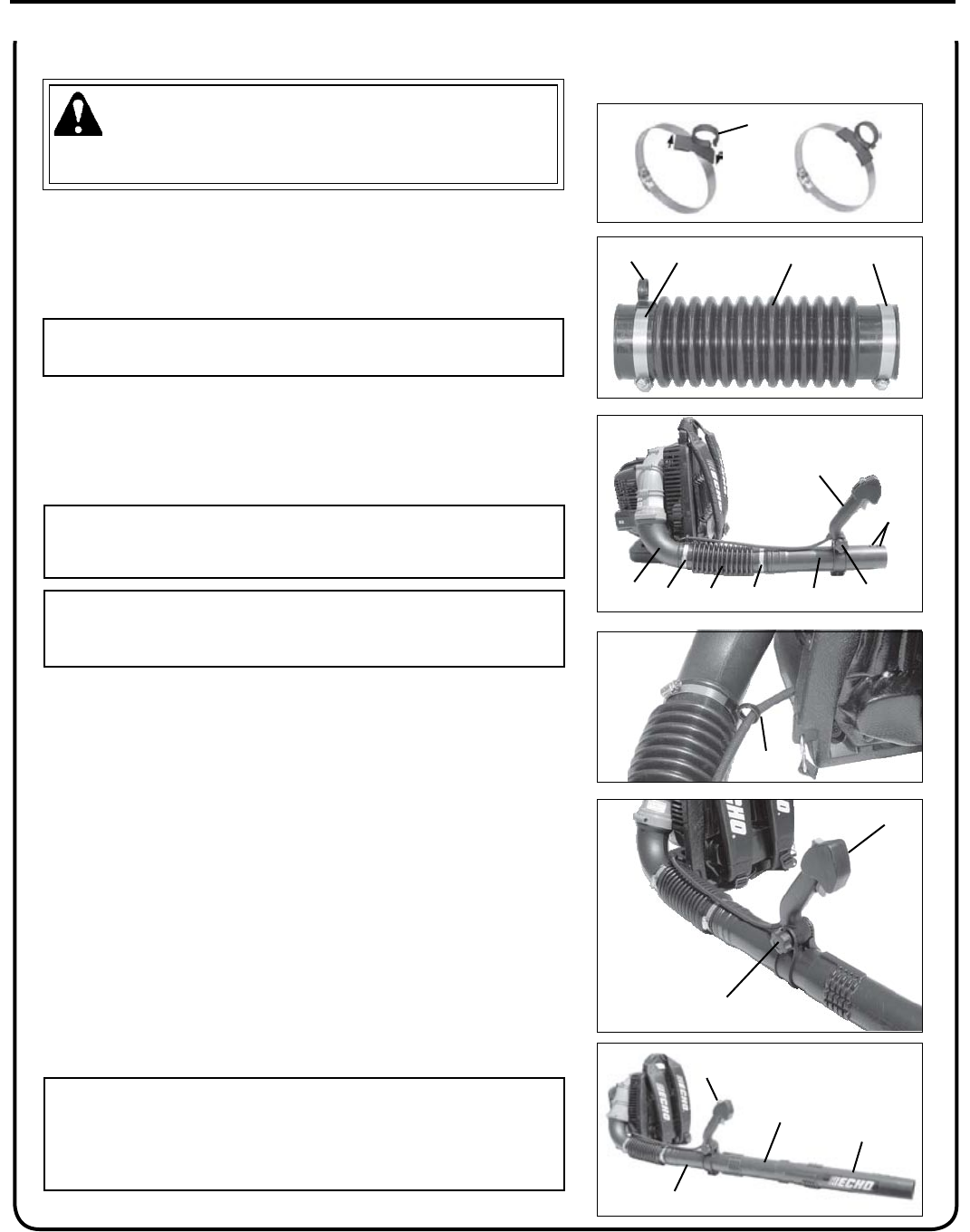

I n s t a l l b l o w e r p I p e s (t)

1. Place guide loop (G) across clamp, and turn until clip fully engages

clamp band.

NOTE

Clamp with cable guide loop (G) ts elbow end of exible pipe (B).

2. Assemble clamps (A) onto both ends of exible pipe (B).

3. Assemble exible pipe (B) to elbow (D) on blower. Position guide

loop (G) on inside (blower side) of exible tube and tighten clamp

(A).

NOTE

A light lubricant may be used to ease assembly of exible pipe to

blower elbow.

NOTE

Hang handle freely from blower to assure throttle cable is not

twisted before installing handle (E).

4. Position cable between the elbow (D) and frame and along the top

of the exible pipe. Loosen knob (H) on handle (E). Align notch in

handle with tabs (F). Install onto swivel pipe (C) past long ridges

in pipe.

5. Assemble swivel pipe (C) into exible pipe (B) and tighten clamp

(A).

6. Clip throttle cable into throttle cable guide loop (G).

7. Move handle (E) to desired position. Tighten knob (H) hand tight.

8. Assemble straight pipe (I) onto swivel pipe (C), until you feel light

resistance. Do not force connection. Hold swivel pipe and turn

straight pipe clockwise, engaging positive locking channels, until

connection is rm. Do not force connection.

9. Assemble straight pipe with decal (J) to straight pipe (I) as in step

8.

NOTE

Blower use will eventually loosen pipe connections. Exclusive

positive locking system allows pipes to be tightened. If loosening

occurs, remove two straight pipes and install according to instruc-

tions 8 & 9.

G

C

A AB

D

F

E

C

G

H

B

E

J

I

A

A

H

E