28

CS-352

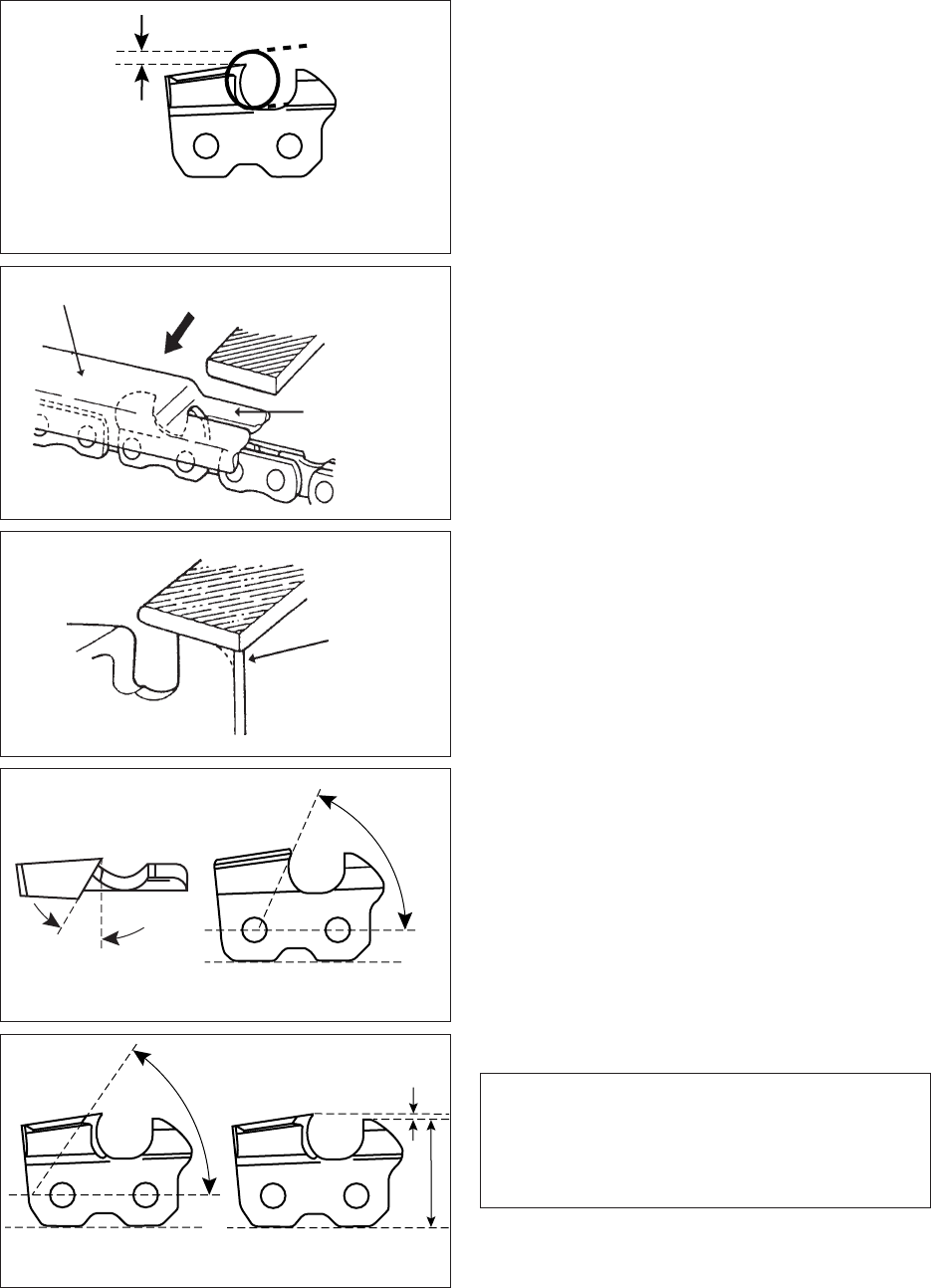

• Place the depth gauge tool firmly on guide

bar so that depth gauge protrudes.

Then file top of depth gauge with the flat file until

flat with top of the depth gauge tool.

- Be sure to round off the front edge of the depth

gauge.

Properly filed cutters are shown in illustration.

When setting of the chain is finished, soak it in oil

and wash away filings completely before using.

- When chain has been filed on the bar, supply

sufficient oil to it, rotate the chain slowly to wash

away the filings before using again.

- If the chain saw is operated with filings clogged

in the groove, the saw chain and the guide bar

will be damaged prematurely.

- If the saw chain becomes soiled with resin, for

instance, clean it with kerosene and soak in it oil.

NOTE

These angles are referred to as Oregon 91P or

91VG.

To sharpen other follow chain manufacturer’s

instruction.

Remove until

flat with tool

Depth gauge tool

Round off

the edge

1/5

One fifth of file diameter remains

above cutter edge

Side plate angleTop plate filing angle

91P :85°

91VG:80°

30°

Parallel

0.64 mm (0.025 in.)

Top plate cutting angle Depth gauge

91P :50°

91VG:60°