Page 9

LOG SPLITTER ASSEMBLY INSTRUCTIONS

NOTE: At least two people are required to lift and

assemble the beam to the reservoir.

12. Remove the beam and stand it upright on the foot

as it would be in use. Roll the reservoir into position

and rotate the reservoir with the tongue until the

holes line up to insert the 5/8” x 4” pivot pin (4337).

Insert a cotter pin (4155) into hole in pin and bend

with pliers to secure. See Figure 6.

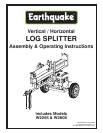

13. Rotate the beam until it is horizontal. Install the

stripper bars (4314) facing upward using four

1/2-13 x 1” bolts (4363) and four 1/2-13 bi-way

locknuts (4117). Install the brush guard (4326)

using four 3/8-16 x 1” bolts (2102) and four 3/8-16

bi-way locknuts (2104). See Figure 7.

14. Remove the high pressure hoses from the parts

box. Install a 60” hose (4210) from the top of the

valve (4100) to the filter (4106). Route the hose

over the top of the tongue and under the beam.

Next, remove the inlet hose (4210 for W2265;

60” long) or (4209 for W2808; 48” long) and install

between the pump outlet and the bottom of the

valve also routing over the tongue and under the

beam.

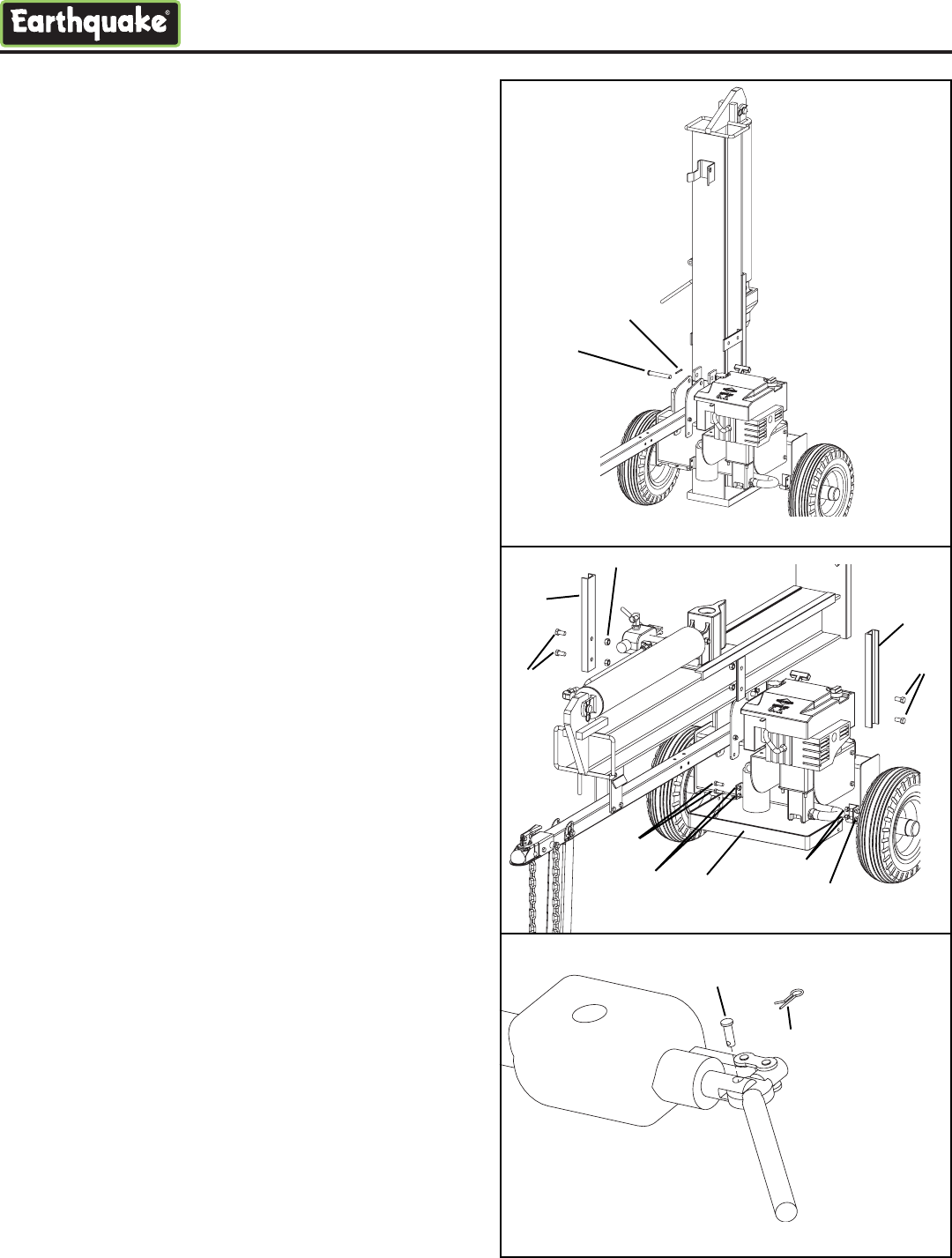

15. Move control valve handle to operation position.

Remove 1/4” pin (4190) and 1/16” cotter pin (4189)

from parts bag and insert pin through hole in control

valve handle and secure with cotter pin. See

Figure 8.

16. Fill the reservoir with hydraulic oil but do not

overflow. Fill the engine with oil and gas as

required. Start the engine and operate the log

splitter running the wedge to the end of the beam

and back until it operates smoothly. Also, check for

leaks under pressure. Tighten as needed. Check

level of fluid in reservoir. Ensure that oil level is on

the dipstick; if not, add oil as needed. If the log

splitter will not operate smoothly, contact your

dealer.

Figure 6

4190

4189

Figure 8

4337

4155

4314

4363

4314

4363

4117

Figure 7

4326

2102

2102 (2)

2104

2104