15

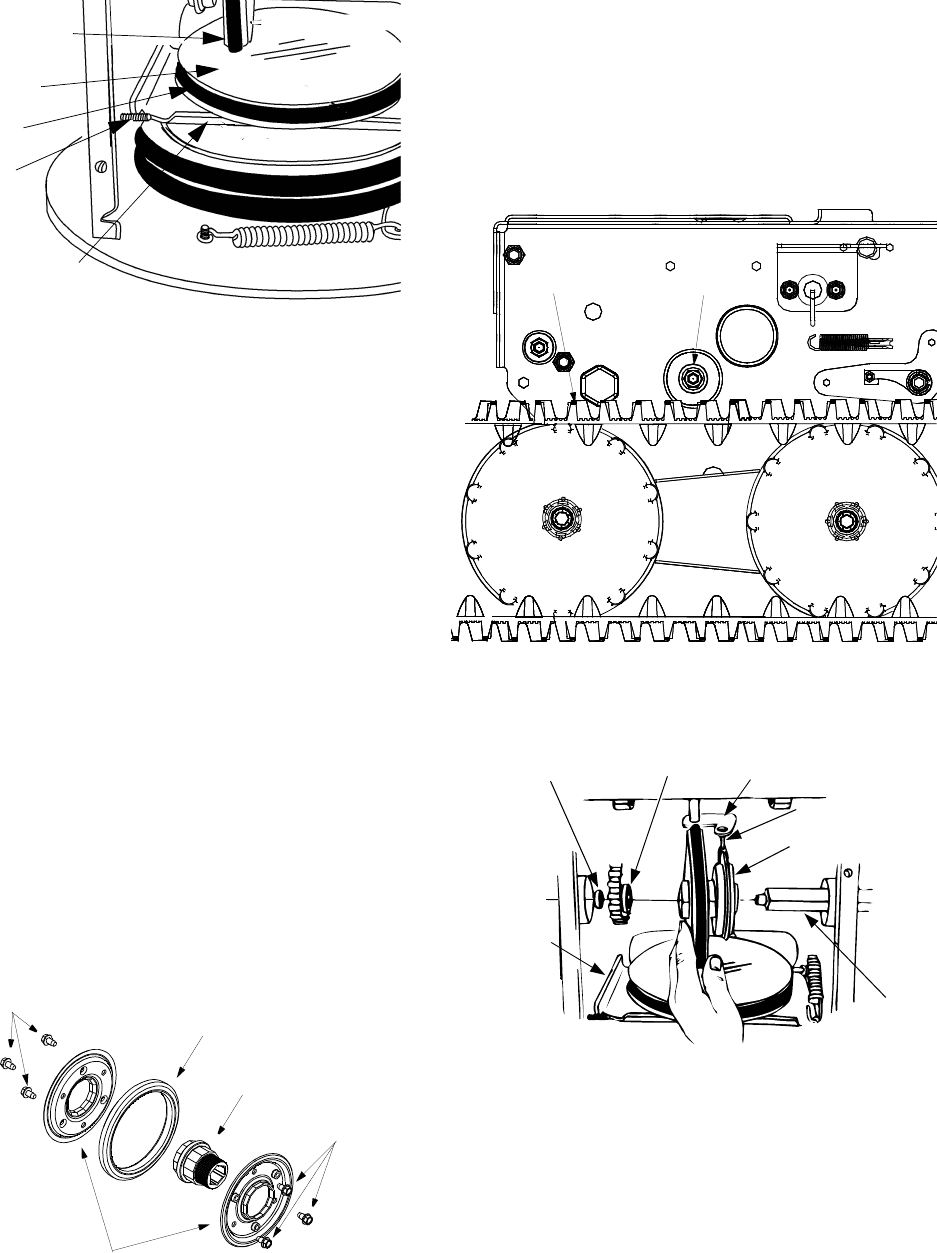

Figure 18

Servicing Friction Wheel Rubber

The rubber on the friction wheel is subject to wear and

should be checked after 25 hours of operation, and

periodically thereafter. Replace the friction wheel

rubber if any signs of wear or cracking are found.

• Drain the gasoline from the snow thrower, or place

a piece of plastic under the gas cap.

• Tip the snow thrower up and forward, so that it rests

on the housing.

• Remove the six self-tapping screws from the frame

cover underneath the snow thrower.

• Using a 7/8" wrench to hold the shaft, loosen, but

do not completely remove, the hex bolt and washer

on the left end of the shaft. See Figure 19 and

Figure 20.

• Lightly tap the hex bolt to dislodge the ball bearing

from the right side of frame before removing the hex

bolt and washer from the left end of the shaft.

• Move the shaft to the right and slide the friction

wheel assembly from the shaft.

• Remove the six screws from the friction wheel

assembly (three from each side). Remove the

friction wheel rubber from between the friction

wheel plates. See Figure 18

Figure 19

• Reassemble the new friction wheel rubber to the

friction wheel plates and hub, tightening the six

screws in rotation and with equal force.

• Position the friction wheel assembly up onto the pin

of the shift rod assembly, and slide the shaft

through the assembly. Reassemble in reverse

order.

NOTE: If you placed plastic film under the gas cap, be

certain to remove it.

Figure 20

Figure 21

Off Season Storage

WARNING: Never store engine with fuel in tank

indoors or in enclosed, poorly ventilated areas where

fuel fumes may reach an open flame, spark or pilot light

as on a furnace, water heater, clothes dryer, or other

gas appliance.

• Clean snow thrower thoroughly.

• Lubricate as instructed above with light oil.

Friction Wheel

Drive Plate

Drive Belt

Support Bracket

Stop Bolt

Friction Wheel Rubber

Screws

Screws

Friction Wheel Plates

Hub

Hex Bolt

Track

Washer

Spacer

Sprocket

Shift Rod

Assembly

Pin

Friction Wheel

Assembly

Support

Bracket

Shaft