25

SECTION IV. MAINTENANCE

ENGINE OIL

The engine-crankcase is filled with ship-away oil. This

oil may be used for the first 5 hours of engine operation

at temperatures between 0° and 90°F. If temperatures

are not within this range, drain the oil from the oil filter

and crankcase and replace with new oil as specified in

the LUBRICATION TABLE. The engine oil must be

drained and replaced with new oil after 5 hours of

engine operation and then after every 50 hours of

operation.

To aid starting, the selection of crankcase lubricating

oils should be based on the lowest anticipated

temperatures until the next scheduled oil change.

Cub Cadet Engine Oil meeting API Service

Classification SG or SH is recommended. For

maximum engine life select API SG or SH oils with

lowest levels of barium, calcium or magnesium

additives and minimum ash content (approximately

0.5%). Lubricant suppliers will normally furnish this

information on their engine oils.

For oil change intervals of 50 hours, the following oils

are recommended.

Ambient Temperature Viscosity (Grade SG/SH)

+40°F and Above — Cub Cadet Engine Oil S.A.E.

30 weight

0° to 40°F — Cub Cadet Engine Oil S.A.E.

5W20 or S.A.E. 5W30*

0°F and below — Synthetic Engine Oil S.A.E.

5W20 or S.A.E. 5W30 only

*Synthetic Engine Oil S.A.E. 5W20 or S.A.E. 5W30 is

acceptable.

Regularly check the oil level of the engine crankcase to

see that it is filled to the correct level. Always keep the

oil level between the “FULL” and the “LOW” marks on

the dipstick. When checking the oil level, the engine

must be cold, the dipstick must be withdrawn and

wiped clean, then screwed all the way into the tube

before being withdrawn for a true reading.

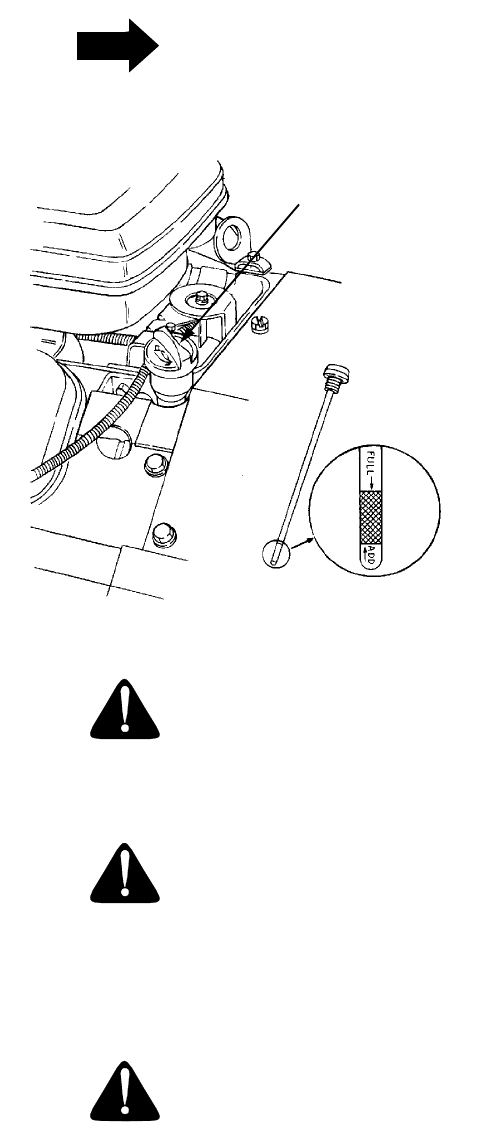

CHECKING THE OIL LEVEL

Before each use, the oil level of the engine crankcase

should be checked to see that it is filled to the correct

level. Close monitoring of the oil level during the first 10

hours of operation of the engine is especially

important. Before checking the oil level, clean the area

around the oil level dipstick to prevent debris from

entering the crankcase. Always keep the oil level

between the “FULL” and the “LOW” marks on the

dipstick (See Figure 20). When checking the oil level,

the engine must be cold, the dipstick must be

withdrawn and wiped clean, then screwed all the way

into the tube before being withdrawn for a true reading.

NOTE

Check the oil level only while the engine is

stopped and the tractor is level.

Figure 20

CAUTION

The oil level should be checked every hour

during the first 5 hours of operation and prior to

every use there after.

CAUTION

The dipstick must be tightened securely when

the engine is operating. Severe engine damage

could result from failure to do so.

ADDING OIL

CAUTION

Never overfill the engine crankcase. The engine

may overheat and/or damage may result if the

crankcase is below the “LOW” mark or over the

“FULL” mark on the dipstick. For best results, fill

to the “FULL” mark on the dipstick as opposed

to adding a given quantity of oil. Always check

the level on the dipstick before adding more oil.

OIL LEVEL

DIPSTICK