Coupler

Lower \

Attachment

Upper Shaft

LOOSEN

TIGHTEN Knob

2= Press and hold the locking/release

button.

Locking/Release

Button

Lower Attachment

3= While securely holding the upper

shaft, pull the attachment straight

out of the coupler.

INSTALLING ATTACHMENT

1= Remove the shaft cap from the at-

tachment (if present) and discard.

2= Position locking/release button of

attachment into guide recess of

upper shaft coupler.

Coupler Primary Hole

Guide Recess

Upper Locking/ Attachment

Shaft Release

Button

3= Push the attachment into the cou-

pler until the locking/release button

snaps into the primary hole.

4= Before using the unit, tighten the

knob securely by turning clock-

wise.

INSTALLING ATTACHMENT

HANGER

An attachment hanger is provided for

storage when attachment is not in use.

To install hanger on attachment:

1= Remove the shaft cap from the at-

tachment (if present) and discard.

2= Press and hold the locking/release

button.

3= Push hanger onto the attachment

until the locking/release button

snaps into the hole.

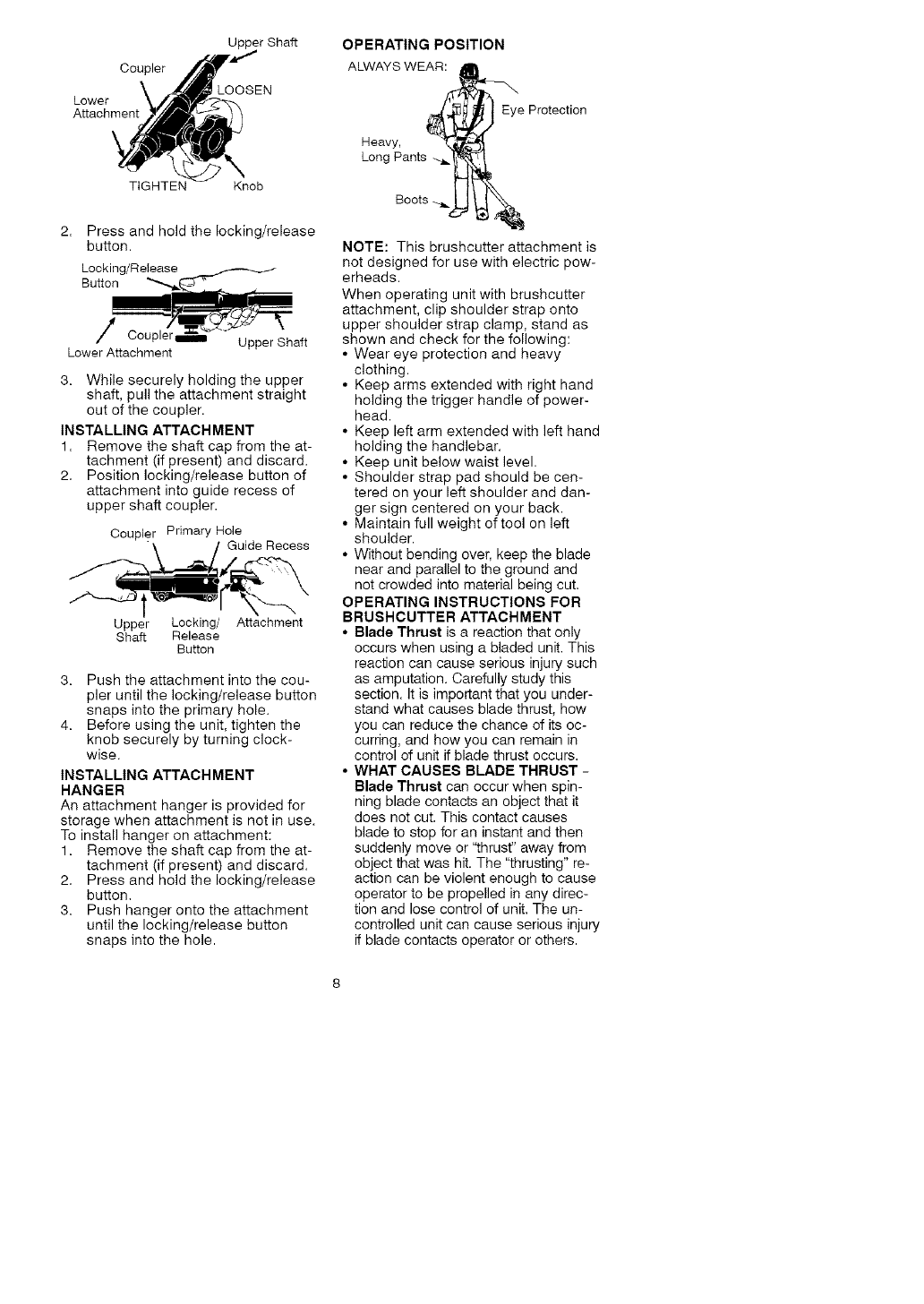

OPERATING POSITION

ALWAYS WEAR:

Heavy,

Lonc

Eye Protection

Boots

NOTE: This brushcutter attachment is

not designed for use with electric pow-

erheads.

When operating unit with brushcutter

attachment, clip shoulder strap onto

upper shoulder strap clamp, stand as

shown and check for the following:

• Wear eye protection and heavy

clothing.

• Keep arms extended with right hand

holding the trigger handle of power-

head.

• Keep left arm extended with left hand

holding the handlebar.

• Keep unit below waist level.

• Shoulder strap pad should be cen-

tered on your left shoulder and dan-

ger sign centered on your back.

• Maintain full weight of tool on left

shoulder.

• Without bending over, keep the blade

near and parallel to the ground and

not crowded into material being cut=

OPERATING INSTRUCTIONS FOR

BRUSHCUTTER ATTACHMENT

• Blade Thrust is a reaction that only

occurs when using a bladed unit. This

reaction can cause serious injury such

as amputation. Carefully study this

section. It is important that you under-

stand what causes blade thrust, how

you can reduce the chance of its oc-

curring, and how you can remain in

control of unit if blade thrust occurs.

• WHAT CAUSES BLADE THRUST -

Blade Thrust can occur when spin-

ning blade contacts an object that it

does not cut. This contact causes

blade to stop for an instant and then

suddenly move or "thrust" away from

object that was hit. The "thrusting" re-

action can be violent enough to cause

operator to be propelled in any direc-

tion and lose control of unit. The un-

controlled unit can cause serious injury

if blade contacts operator or others.