CLEAN AIR SCREEN

Airscreenmustbekeptfreeof dirtand

chaffto preventenginedamagefromover-

heating.Cleanwitha wire brush or com-

pressed air to remove dirt and stubborn

dried gum fibers.

AIR FILTER

Yourengine will not run properly using a

dirtyair filter. Clean the foam pre-cleaner

after every 25 hours of operation or every

season. Service paper cartriage every

100 hours of operation or every season,

whichever occurs first.

Service air cleaner more often under dusty

conditions.

• Remove knob and cover.

• Remove wing nut and air cleaner from

base.

TO SERVICE PRE-CLEANER

• Slide foam pro-cleaner off cartddge.

• Wash it in liquid detergent and water.

• Squeeze it dry in a clean cloth. Allow it

to dry.

• Saturate it in engine oil. Wrap it in

clean, absorbent cloth and squeeze to

remove excess oil.

TO SERVICE CARTRIDGE

• Replace a dirty, bent, or damaged car-

tridge.

NOTE: Do not wash the paper cartridge

or use pressurized air, as this will damage

the cartddge.

• Reinstall the pre-cieaner (cleaned and

oiled) over the paper cartridge.

• Reassemble air cleaner, wing nut, cover

and tighten knob securely.

CLEAN AIR INTAKE/COOLING AREAS

To insure proper cooling, make sure the

grass screen, cooling fins, and other

external surfaces of the engine are kept

clean at all times.

Every 100 hours of operation (more often

under extremely dustyrdi_y conditions),

remove the blower housing and other

cooling shrouds. Clean the cooling fins

and external surfaces as necessary. Make

sure the cooling shrouds are reinstalled.

NOTE: Operating the engine with a

blocked grass screen, dirty or plugged

cooling fins, and/or cooling shrouds re-

moved will cause engine damage due to

overheating.

MUFFLER

Inspect and replace corroded muffler and

spark arrester (if equipped) as it could cre-

ate a fire hazard and/or damage.

SPARK PLUGS

Replace spark plugs at the beginning of

each mowing season or after every 100

hours of operation, whichever occurs first.

Spark plug type and gap setting are

shown in uPRODUCT SPECIFICATIONS"

section of this manual.

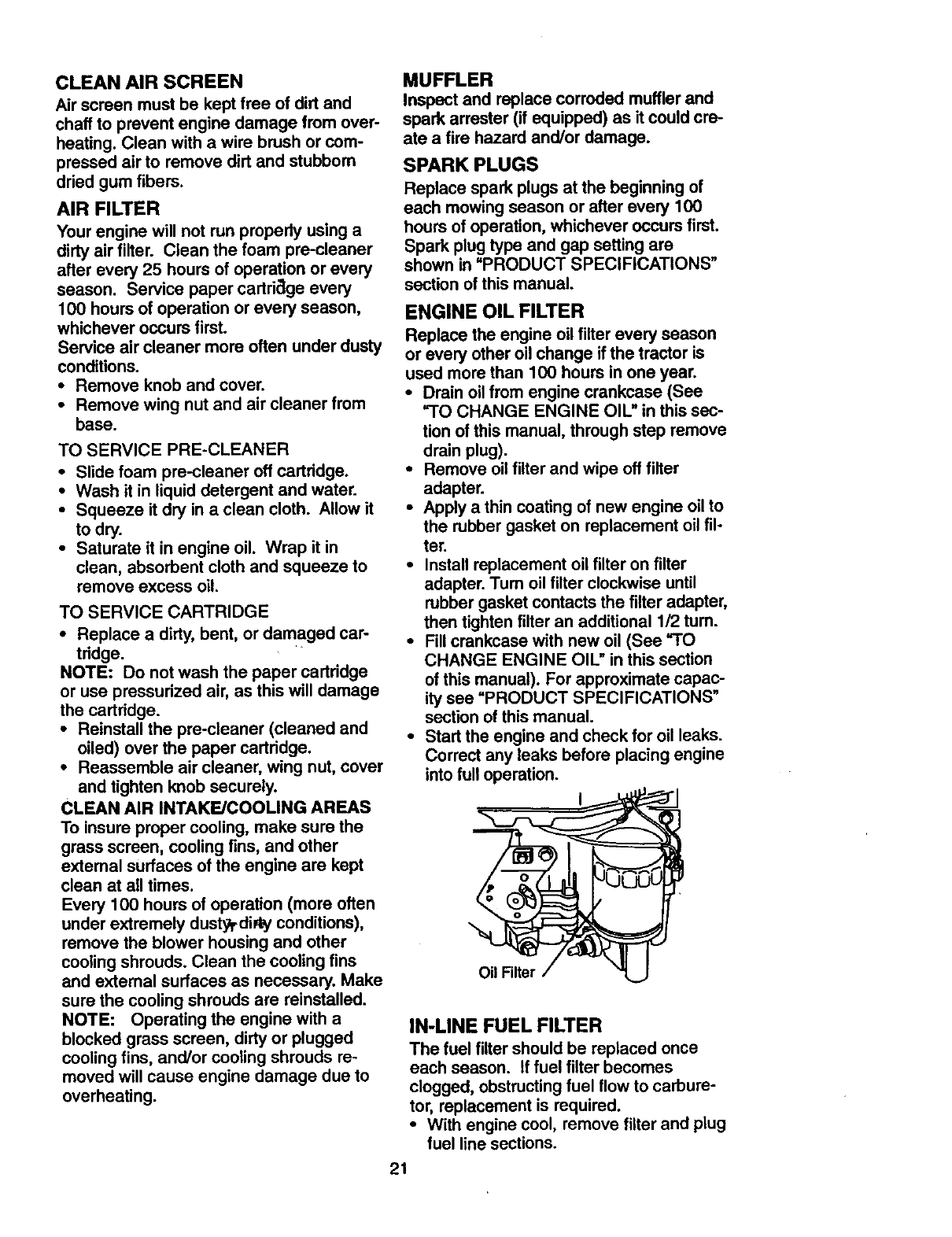

ENGINE OIL FILTER

Replace the engine oil filter every season

or every other oil change if the tractor is

used more than 100 hours in one year.

• Drain oil from engine crankcase (See

=TO CHANGE ENGINE OIL" in this sec-

tion of this manual, through step remove

drain plug).

• Remove oil filter and wipe off filter

adapter.

• Apply a thin coating of new engine oil to

the rubber gasket on replacement oil fil-

ter.

• Install replacement oil filter on filter

adapter. Turn oil filter clockwise until

rubber gasket contacts the filter adapter,

then tighten filter an additional 1/2 turn.

• Fill crankcase with new oil (See =TO

CHANGE ENGINE OIL" in this section

of this manual). For approximate capac-

ity see "PRODUCT SPECIFICATIONS"

section of this manual.

• Start the engine and check for oil leaks.

Correct any leaks before placing engine

into full operation.

Oil Filter /

IN-LINE FUEL FILTER

The fuel filter should be replaced once

each season. If fuel filter becomes

clogged, obstructing fuel flow to carbure-

tor, replacement is required.

• With engine cool, remove filter and plug

fuel line sections.

21