TO REMOVE HOOD AND GRILL AS-

SEMBLY

• Raise hood.

Unsnap headlight wire connector.

• Stand Jnfront of tractor. Grasp hood at

sides, tilt toward engine and lift off of

tractor.

• To replace, reverse above procedures.

Connector

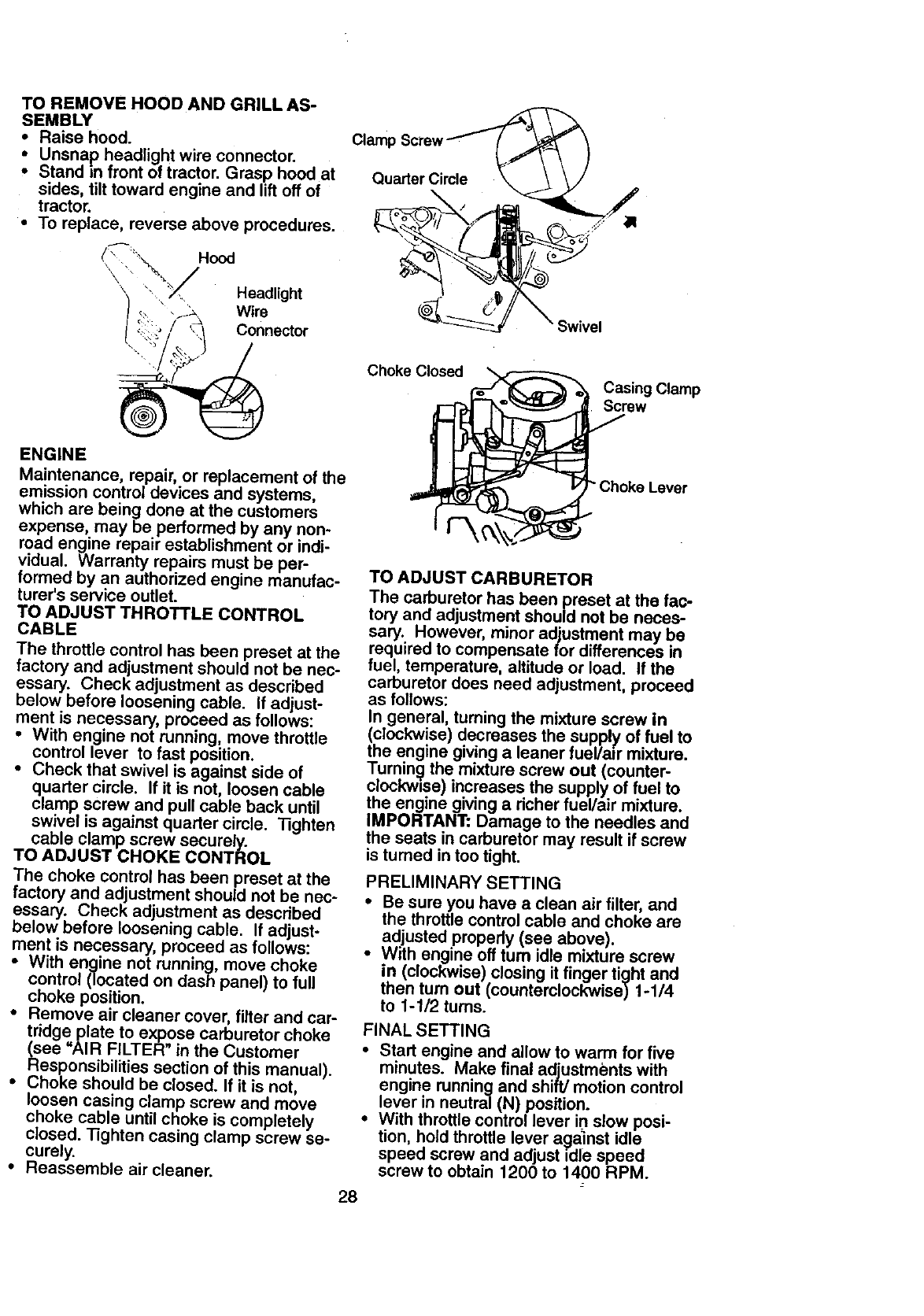

Clamp Screw

Quarter Circle

Choke Closed

Casing Clamp

Screw

ENGINE

Maintenance, repair, or replacement of the

emission control devices and systems,

which are being done at the customers

expense, may be performed by any non-

road engine repair establishment or indi-

vidual. Warranty repairs must be per-

formed by an authorized engine manufac-

turer's service outlet.

TO ADJUST THROTTLE CONTROL

CABLE

The throttle control has been preset at the

factory and adjustment should not be nec-

essary. Check adjustment as described

below before loosening cable, if adjust-

ment is necessary, proceed as follows:

• With engine not running, move throttle

control lever to fast position.

• Check that swivel is against side of

quarter circle. If it is not, loosen cable

clamp screw and pull cable back until

swivel is against quarter circle. Tighten

cable clamp screw securely.

TO ADJUST CHOKE CONTROL

The choke control has been preset at the

factory and adjustment should not be nec-

essary. Check adjustment as described

below before loosening cable. If adjust-

ment is necessary, proceed as follows:

• With engine not running, move choke

control (located on dash panel) to full

choke position.

• Remove air cleaner cover, filter and car-

tridge plate to expose carburetor choke

(see "AIR FILTER" in the Customer

Responsibilities section of this manual).

• Choke should be closed. If it is not,

loosen casing clamp screw and move

choke cable until choke is completely

closed. Tighten casing clamp screw se-

curely.

• Reassemble air cleaner.

Choke Lever

TO ADJUST CARBURETOR

The carburetor has been preset at the fac-

tory and adjustment should not be neces-

sary. However, minor adjustment may be

required to compensate for differences in

fuel, temperature, altitude or load. If the

carburetor does need adjustment, proceed

as follows:

In general, turning the mixture screw in

(clockwise) decreases the supply of fuel to

the engine giving a leaner fuel/air mixture.

Turnin_ the mixture screw out (counter-

clockwzse) increases the supply of fuel to

the engine giving a richer fuel/air mixture.

IMPORTANT" Damage to the needles and

the seats in carburetor may result if screw

is turned in too tight.

PRELIMINARY SETTING

• Be sure you have a clean air filter, and

the throttle control cable and choke are

adjusted properly (see above).

• With engine off turn idle mixture screw

in (clockwise) closing it finger tight and

then turn out (counterclockwise) 1-1/4

to 1-1/2 turns.

FINAL SETTING

• Start engine and allow to warm for five

minutes. Make final adjustments with

engine running and shift/motion control

lever in neutral (N) position.

• With throttle control lever in slow posi-

tion, hold throttle lever a_ainst idle

speed screw and adjust idle speed

screw to obtain 1200 to 1400 RPM.

28