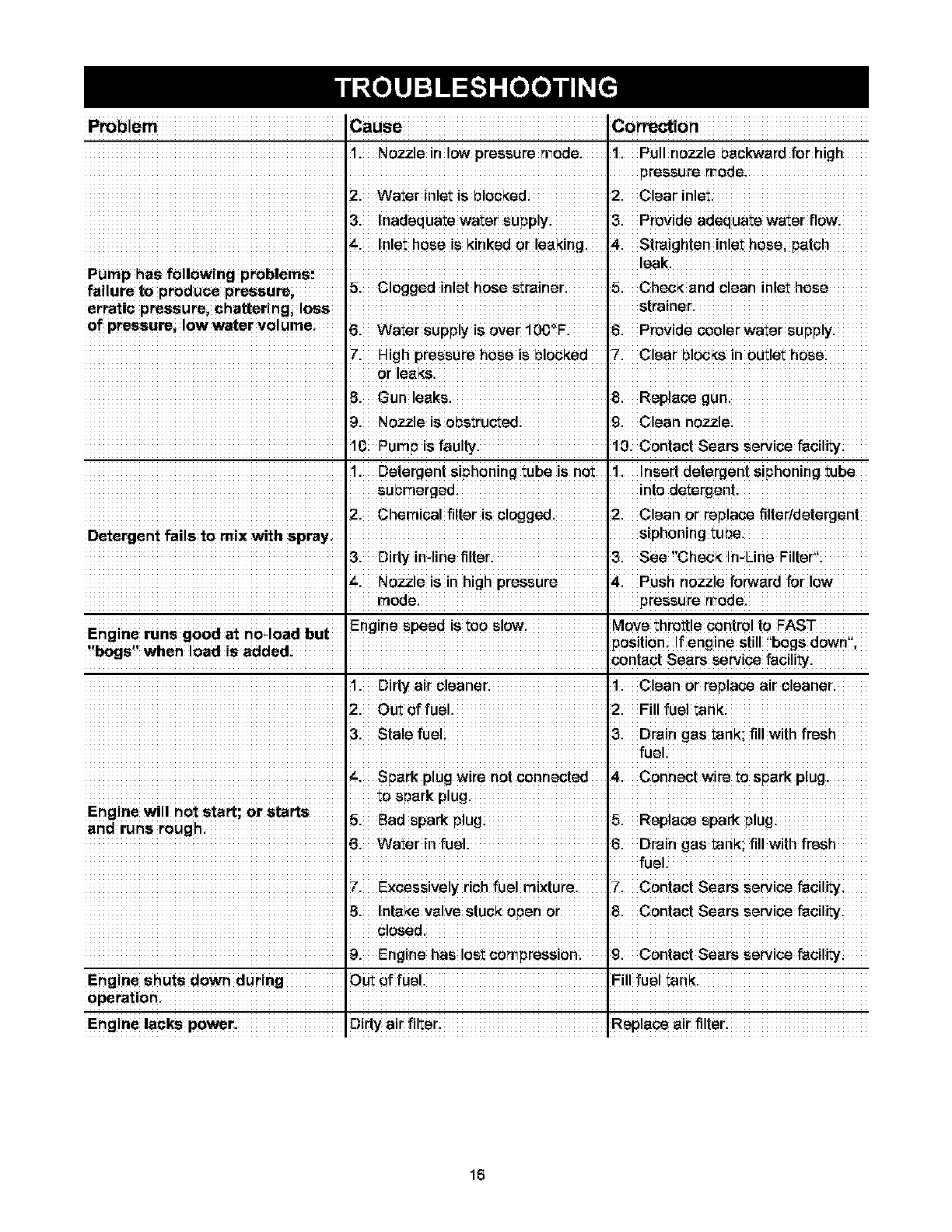

CaLISQ Co--Jot1

!i NOzzle in !ow pressure mode. !. Pu!! nezz!e backward for high

2. Water inlet is block:ed: ................ 2. cleariniet.

3i Inadequate wal:er sUpp!y. 3. Provide adequate water flowi

_-. Inlet h0se is _:inked or leaking. 4. Straighten inlet hose; patch

leak,

Pump has following problems:

failure to produce pressumi 5i C Ogged n et hOSestra neri CheCk:and € ean n e_hOSe

erratic pressUrei chatteringi ioss strainer.

of pressure;!ow water v0!ume; 6. water Supply is over i00_F. 16. ProVide cooler water Supply

High pressure hose is blocked Clear blOck:sin Outlethosei

orleahcsi i

8. Gunieaks.

9i Nozzle is obs_uctedi g. Clean nozzlei

!0; PUmp is fau!ty. ! O. ContaPt Sears se_ico facility

li Detergent Siphoning tube is not 1. Insert detergent siphoning l:ube

.submerged into del:ergent.

2. Chemical filter is clogged. 2. Clean or replace filter/detergent

Detergent fai!s t0 mix with Sprayi Siphoning tU_e•

3i Di_ in-line f!!ter. 3. see i'check in--L!ne Fi!ter"

_. Nozzle is in high pressure 4. Push nozz!e forward for !ow

Engine speed is t0o s!ow Move thrott!e _ntr01 to FAST

,,_,_e _r_, gooo a_ =o_oao If engine Still t'b0gs down'i,

•...,_--.._,.._=_ '_ J jcontactsears se_ico facility

li Dirty air cleaneri

2i outeffueli 2. Fillfuell:an_i

3. Sta!e fuel ................................... 3. Drain gas l:ank:;fi!! with fresh .......

fuel.

spark plug wire not connected 4. Connect wire _ spark plug.

_0 sparkplug. I

5 Bad spark piUg '5. Repiacasparkpiug

and runs rough, ,

6i water in fueli 6. Drain gas l:ank:;fillWith fresh

fuel

7i Excassively rich fuel mixture. 7. Contact Sears service facilityi

8i Infa_e valve stuck open or .8. Contact Sears service facilityi

closed. I

gi Engine has los1:compressioni g. Contact Sears service facility:

Engine shuts down during Out 0f fuel. Fill fuei _ank.

operationi J

Engine lacks power. Di_ air fi!teri Rep!a_ air fi!teri

16