7

AIR FILTER MAINTENANCE

The condition of the air filter is important

to the operation of the unit. A dirty air

filter will restrict air flow and change the

air/fuel mixture. This is often mistaken

for an out of adjustment carburetor.

Check the condition of the air filter

before adjusting the idle speed screw.

Refer to Air Filter Maintenance.

Removing the Air Filter/Muffler

Cover

1. Remove the four (4) screws

securing the air filter/ muffler

cover (Fig. 14). Use a flat blade

or T20 Torx bit screwdriver.

2. Pull the cover from the

engine. Do not force.

Cleaning the Air Filter

Failure to maintain your air

filter properly can result in

poor performance or can

cause permanent damage to

your engine.

1. Remove air filter/muffler

cover. Refer to Removing

the Air Filter/Muffler

Cover above.

2.

Turn cover over and look

inside to locate the air filter.

Remove the air filter from

inside the air filter/muffler

cover (Fig. 15).

3. Wash the filter in detergent

and water (Fig. 16). Rinse

the filter thoroughly.

Squeeze out excess water.

Allow it to dry completely.

4. Apply enough clean SAE

30 oil to lightly coat the

filter (Fig. 17).

5. Squeeze the filter to

spread and remove

excess oil (Fig. 18).

6. Replace the air filter

inside the air filter/muffler

cover (Fig. 15).

NOTE: Operating the unit

without the air filter

and air filter/muffler

cover assembly will

VOID the warranty.

Reinstalling the Air

Filter/Muffler Cover

1. Place the air filter/muffler

cover over the back of the

carburetor and muffler.

Align the screw holes.

2. Insert the four (4) screws

into the holes in the air

filter/muffler cover (Fig.

14) and tighten. Do not

over tighten.

MAINTENANCE & REPAIR INSTRUCTIONS

WARNING:

To avoid

serious personal injury,

always turn your unit off

and allow it to cool before

you clean or service it.

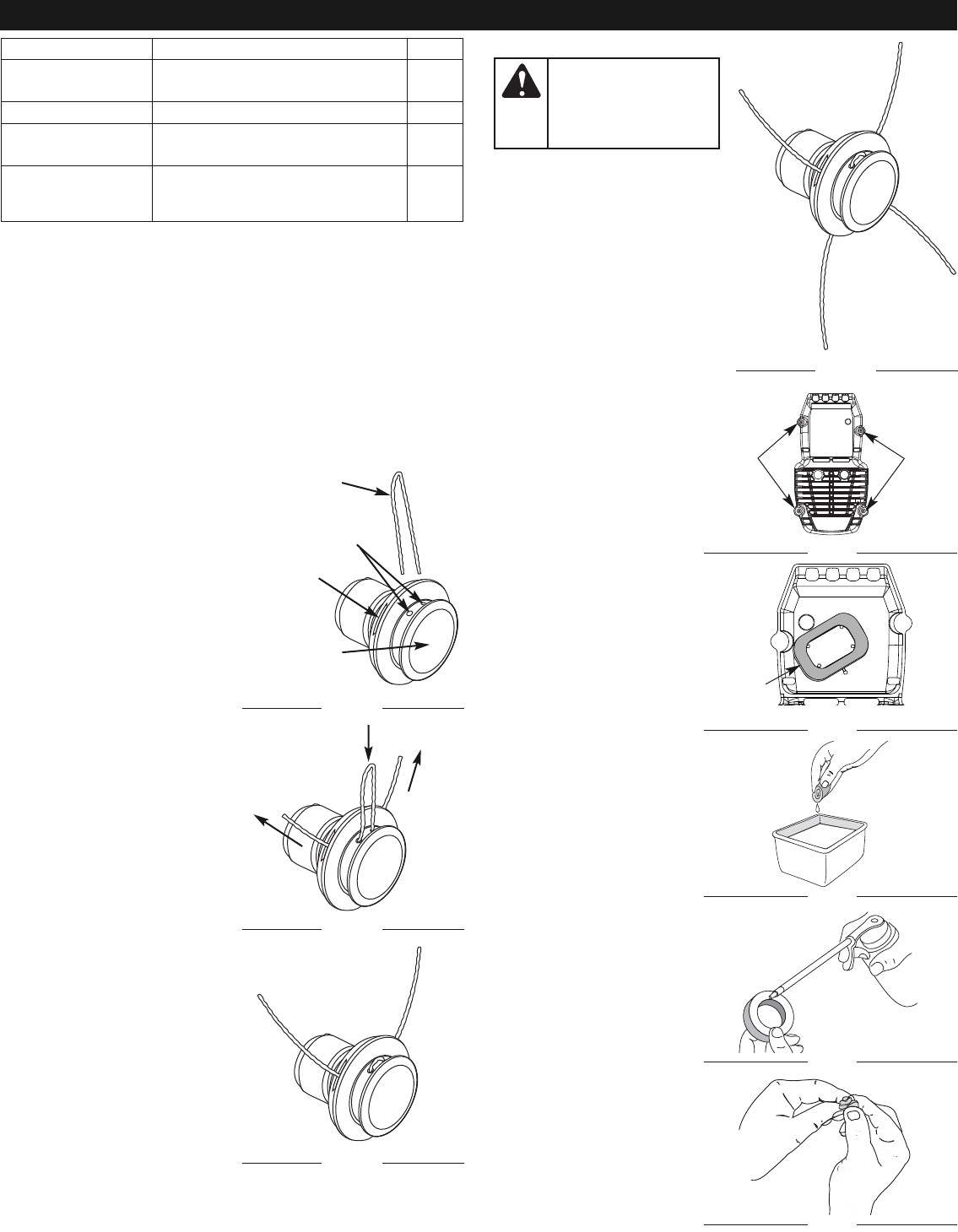

LINE REPLACEMENT

for Hassle-Free™ Plus Cutting Head

Always use Craftsman Hassle-Free™ XTRA QUIET Spiral Line.

Choose the line size best suited for the job at hand. Red colored line

is designed for cutting grass and small weeds. Black colored line is

designed for cutting larger weeds and light brush.

NOTE: Before inserting new line into the holes in the cutting head,

identify the proper holes. Follow directions as shown on the

glide plate. Do Not attempt to remove the cutting head from

the unit when replacing line.

NOTE: Do not mix lines. Use 2 black or 2 red only.

1. Remove the old line and line glide plate from the cutting head.

2. Clean entire surface of cutting head.

3. Reinstall line glide plate (Fig. 10).

The glide plate is a keyed item

and will only fit one way. If it does

not go into the cutting head

smoothly, DO NOT force it.

Rotate the glide plate until it

slides into the cutting head easily.

NOTE: The glide plate must be

installed in the cutting head

before inserting new line.

4. Insert both ends of your line

through the insertion holes in the

side of the cutting head (Fig. 10).

5.

Push and/or pull the line so that

the line is snug against the hub

and is fully extended through the

positioning tunnels (Fig. 11).

6. Correctly installed line will be

the same length on both sides

(Fig. 12).

NOTE: Make sure that when

installing new line, that the

line is as close to even as

possible. Any variation in

lengths may cause the unit

to vibrate excessively. If this

happens, stop the unit and

make sure the line is even.

7. Repeat steps 4 thru 6 to install

the second trimmer line.

8. Correctly installed, the four

lines will all be the same

length (Fig. 13).

Some line breakage will occur from:

• Entanglement with foreign matter

• Normal line fatigue

• Attempting to cut thick, stalky

weeds

• Forcing the line into objects

such as walls or fence posts

NOTE: During normal use the

trimming line may become worn unevenly which may cause

excessive vibrations in the unit. If this becomes

uncomfortable or uncontrollable, stop the unit and replace

the line. Refer to the Line Replacement instructions above.

FREQUENCY MAINTENANCE REQUIRED SEE

Before starting

engine

Fill fuel tank with fresh fuel p. 5

Every 10 hours Clean and re-oil air filter p. 7

Every 25 hours Check and clean spark arrestor

Check spark plug condition and gap

p. 8

p. 8

Every 50 hours Inspect exhaust port and spark

arrestor screen for clogging or

obstruction

p. 8

Screws

Fig. 14

Screws

Air Filter

Fig. 15

Fig. 16

Fig. 17

Fig. 18

Inside Muffler C over

Positioning

Tunnel

Trimming

Line

Fig. 10

Insertion

Holes

Glide Plate

Fig. 11

Fig. 12

Fig. 13