ShreddingBlade

Theshreddingblade may be removed for sharpening

or replacement as follows.

• Disconnect spark plug wire and move it away

from spark plug.

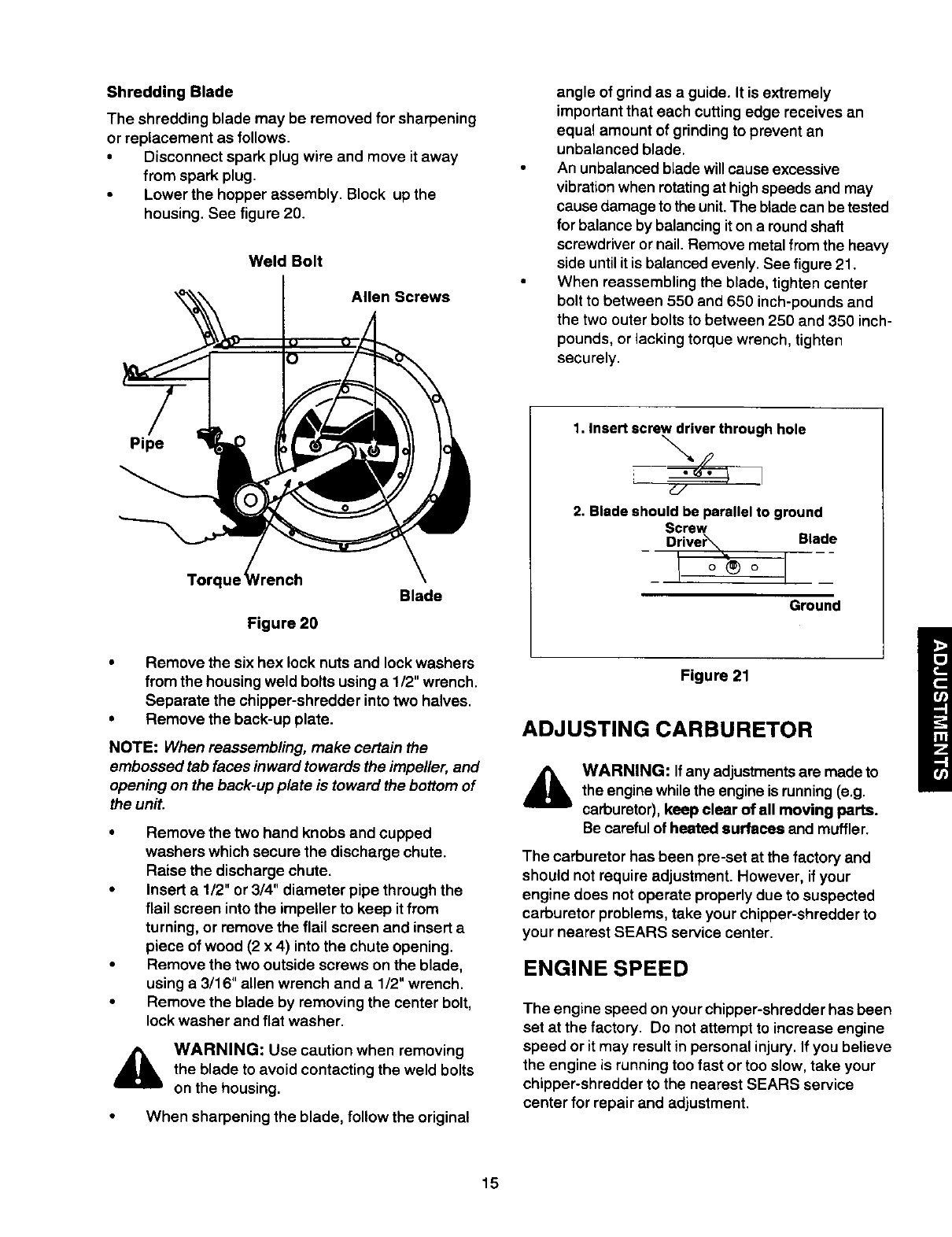

• Lower the hopper assembly. Block up the

housing. See figure 20.

Weld Bolt

Allen Screws

Pipe

Blade

Figure 20

• Remove the six hex lock nuts and lockwashers

from the housing weld bolts using a 1/2" wrench.

Separate the chipper-shredder intotwo halves.

• Remove the back-up plate.

NOTE: When reassembling, make certain the

embossed tab faces inward towards the impeller, and

opening on the back-up plate is toward the bottom of

the unit.

• Remove the two hand knobs and cupped

washers which secure the discharge chute.

Raise the discharge chute.

• Insert a 1/2" or 3/4" diameter pipe through the

flail screen into the impeller to keep it from

turning, or remove the flail screen and insert a

piece of wood (2 x 4) into the chute opening.

• Remove the two outside screws on the blade,

using a 3/16" allen wrench and a 1/2" wrench.

• Remove the blade by removing the center bolt,

lock washer and flat washer.

_hL WARNING: Use caution when removing

the blade toavoid contacting the weld bolts

on the housing.

• When sharpening the blade, follow the original

angle of grind as a guide. It is extremely

important that each cutting edge receives an

equal amount of grinding to prevent an

unbalanced blade.

An unbalanced blade willcause excessive

vibrationwhen rotatingat highspeeds and may

cause damage totheunit.The blade can be tested

for balance by balancing it on a roundshaft

screwdriver ornail. Remove metal from the heavy

side untilitisbalanced evenly. See figure 21.

When reassembling the blade, tighten center

bolt to between 550 and 650 inch-pounds and

the two outer bolts to between 250 and 350 inch-

pounds, or lacking torque wrench, tighten

securely.

I. Insert screw driver through hole

d./

2. Blade should be parallel to ground

Scre_

Driver'_ Blade

_1 o' ol--

Ground

Figure 21

ADJUSTING CARBURETOR

WARNING: If any adjustmentsare made to

the engine whilethe engine is running(e.g.

carburetor),keep clear of all moving parts.

Be careful ofheated surfaces and muffler.

The carburetor has been pre-set at the factory and

should not require adjustment. However, if your

engine does not operate properly due to suspected

carburetor problems, take your chipper-shredder to

your nearest SEARS service center.

ENGINE SPEED

The engine speed on your chipper-shredder has been

set at the factory. Do not attempt to increase engine

speed or it may result in personal injury. If you believe

the engine is running too fast or too slow, take your

chipper-shredder to the nearest SEARS service

center for repair and adjustment.

15