NOTE

If driveline is the correct length, omit the following

steps “G” through “J” and proceed to step “K”.

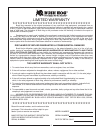

G. Clamp driveline in a well padded vice to pre-

vent damage to the shield. Cut off shield where

marked. (Figure 2-3)

H. Using cut off section of shield as a guide, cut

shaft the same amount. (Figure 2-4)

Figure 2-4

I. Repeat steps “G” and “H” to other driveline

section.

J. Deburr ends of driveline sections and clean

away all chips and fillings. (Figure 2-5)

K. Apply multi-purpose grease to inside of outer

(female) driveline section. Assemble driveline and

install on tractor and tiller. Pull on each driveline sec-

tion to be sure yokes lock into place. Make certaqin

driveline shielding is in place and in good condition.

Figure 2-3

Figure 2-5

DANGER

L. Adjust lower lift arm to level tiller right to left.

Refer to tractor operator’s manual for instructions.

M. Adjust top link of tractor 3-point hitch to level

tiller front to rear.

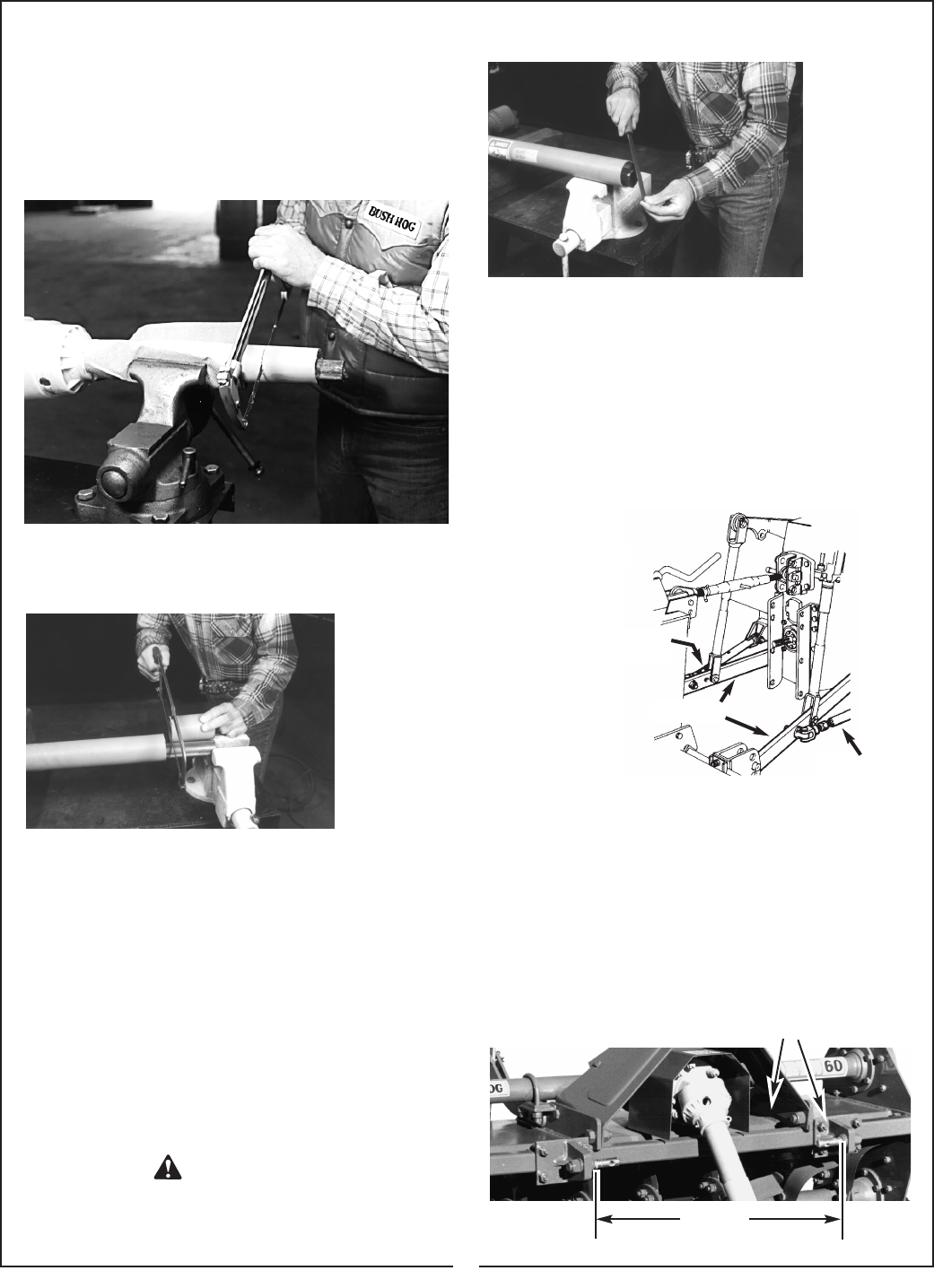

N. Set up tractor stabilizer bars, sway blocks, or

equivalent to prevent implement side sway. (Figure 2-6)

2-2 OFFSETTING 3-POINT HITCH

(RTN Series)

The lower hitch pins on the RTN series can be offset

up to 6 inches to either side as follows:

A. Loosen clamp bolts on hitch pin that will move

outward and slide to desired position.

B. Remove opposite hitch pin bracket and replace it

between clutch shield and “A” frame. A distance of 26-

7/8” , measured as shown in Figure 2-7, must be main-

tained between pins.

C. Tighten clamp bolts.

Figure 2-7 Lower Hitch Pins - May Be Relocated

MAKE CERTAIN DRIVELINE YOKES ARE

SECURELY FASTENED. FAILURE TO DO SO

MAY RESULT IN SERIOUS INJURY.

Figure 2-6

26-7/8”

Stabilizer

Stabilizer

Stabilizer Bars

Lift Arms

8