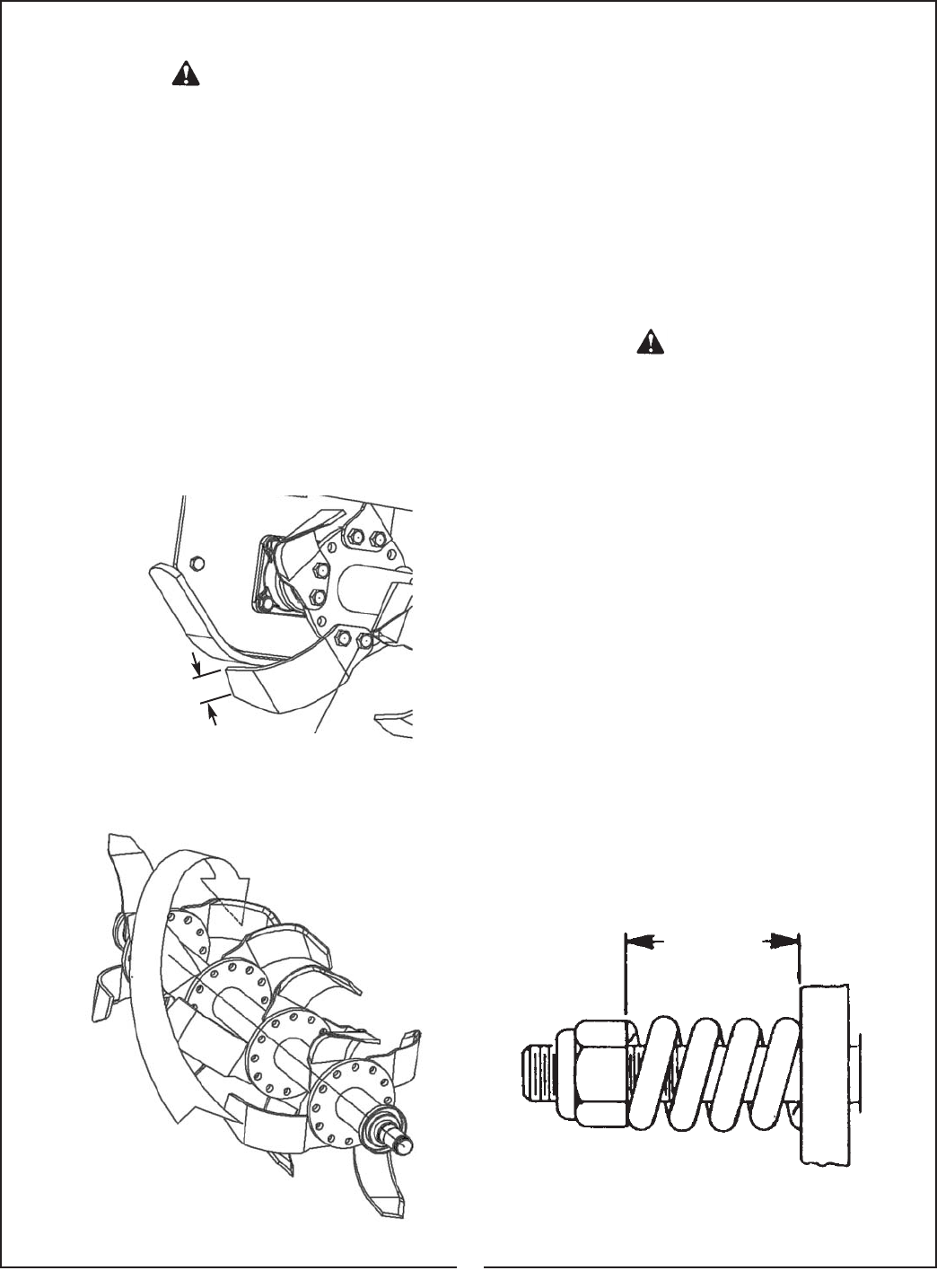

4-3 BLADE REPLACEMENT

Tiller blades should be replaced when they have

approximately 1/4” of wear left on tip of blade.(Figure

4-7) To replace blades, remove bolts securing blade.

Install new blade in its place. Blade must be a right

or left corresponding to the blade removed. Pay spe-

cial attention to the bolts on the blades; the bolt head

must be placed on the blade side, with the washer

and the nut on the flange side so that the bolts can-

not loosen while the equipment is being used. When

several blades must be replaced, replace one blade

at a time, so that the initial layout is maintained.

(Figure 4-8) Tighten blade bolts to 70 ft. lbs. Use

only genuine Bush Hog replacement parts.

WARNING

THE TILLER CAN FALL FROM

HYDRAULIC SYSTEM FAILURE. TO

AVOID SERIOUS INJURY OR DEATH,

SECURELY SUPPORT TILLER BEFORE

WORKING UNDERNEATH.

Figure 4-9

Clutch Spring Length

1-1/16”

(27mm)

12

4-4 SLIP CLUTCH OPERATIONAL

CHECK

After tiller has been stored for 30 days or more,

perform the following operational check:

A. Loosen eight nuts retaining clutch springs

exactly one full turn.

B. With tiller blades firmly on ground and tractor

at idle speed, engage tractor PTO drive for 2-3 sec-

onds. Clutch should slip without turning blades. If

clutch does not slip, contact your authorized Bush

Hog dealer.

C. Retighten nuts to within 1/64” of original position.

Initial spring length is 1-1/16” (27mm). (Figure 4-9)

4-5 SLIP CLUTCH ADJUSTMENT

The slip clutch is factory preset to the correct torque

for protecting implement and tractor. Periodic

adjustment is recommended; refer to Section 4-4.

Should adjustment be needed, first check to be sure

all spring lengths are within 1/64” of being the same.

Initial spring length is 1-1/16” (27mm) shown in

Figure 4-9. If necessary, loosen nut on any spring

that is unequal. Adjust all eight spring retaining nuts

2/3 of a turn (2 flats on a nut) and check clutch slip-

page. If further adjustment is necessary, do so in 1/3

turn increments or consult your Bush Hog dealer.

Adjust only to provide sufficient torque to prevent

slippage under normal conditions. When rocks, roots,

etc. are present, occasional slippage is normal for

drivetrain protection.

CAUTION

FAILURE TO RETIGHTEN SPRING NUTS

TO ORIGINAL POSITION MAY CAUSE

DAMAGE TO TILLER AND/OR TRACTOR

DUE TO IMPROPER SLIP CLUTCH

TORQUE SETTING.

Figure 4-7

Bolt Head

Against Blade

Figure 4-8

Helical Arrangement

1/4” Minimum