16 BRIGGSandSTRATTON.COM

High Temperature (FC_7)

This fault is indicated by fault code FC_7 and seven blinks on

the LED indicator. The contacts of the coolant temperature

switch are normally open. If the engine coolant temperature

exceeds approximately 115.5°C (240°F), the fault is detected

and the engine shuts down.

Common causes for this condition include running the

unit with all access doors removed, obstructed air inlet or

exhaust port, low oil or coolant level, or debris in the engine

compartment or radiator.

To resolve the problem, let the engine cool down and remove

any accumulated debris and obstructions. Ensure that the

access doors are installed whenever the unit is running.

Transfer Switch Fault (FC_8)

This fault is indicated by fault code FC_8 and eight blinks on

the LED indicator (if transfer switch is equipped with fault

detection). The most likely cause of this fault is a blown fuse

in the transfer switch.

To remedy the problem, contact your installer or a Briggs &

Stratton Authorized Dealer.

Generator Maintenance

The generator warranty does not cover items that have been

subjected to operator abuse or neglect. To receive full value

from the warranty, the operator must maintain the system as

instructed in the engine operator’s manual.

All adjustments should be made at least once each season.

Follow the requirements in the engine operator’s manual.

Generator maintenance consists of keeping the unit clean.

Operate the unit in an environment where it will not be

exposed to excessive dust, dirt, moisture or any corrosive

vapors. Cooling air louvers on the enclosure must not

become clogged with snow, leaves, or any other foreign

material.

Check the cleanliness of the unit frequently and clean when

dust, dirt, oil, moisture or other foreign substances are

visible on its exterior/interior surface.

NOTE: DO NOT use direct spray from a garden hose to clean

generator. Water can enter the engine and generator and

cause problems.

Engine Maintenance

An engine manual was packaged with this system. Please

refer there for all engine-related maintenance topics.

However, proper engine cooling and lubrication are so

important we give them special mention here.

Engine Oil

The system is filled with the recommended non-synthetic oil

(API SL 10W-30W). This allows for system operation in a

wide range of temperature and climate conditions.

NOTE: Refer to the engine operator’s manual for

recommended oil change intervals.

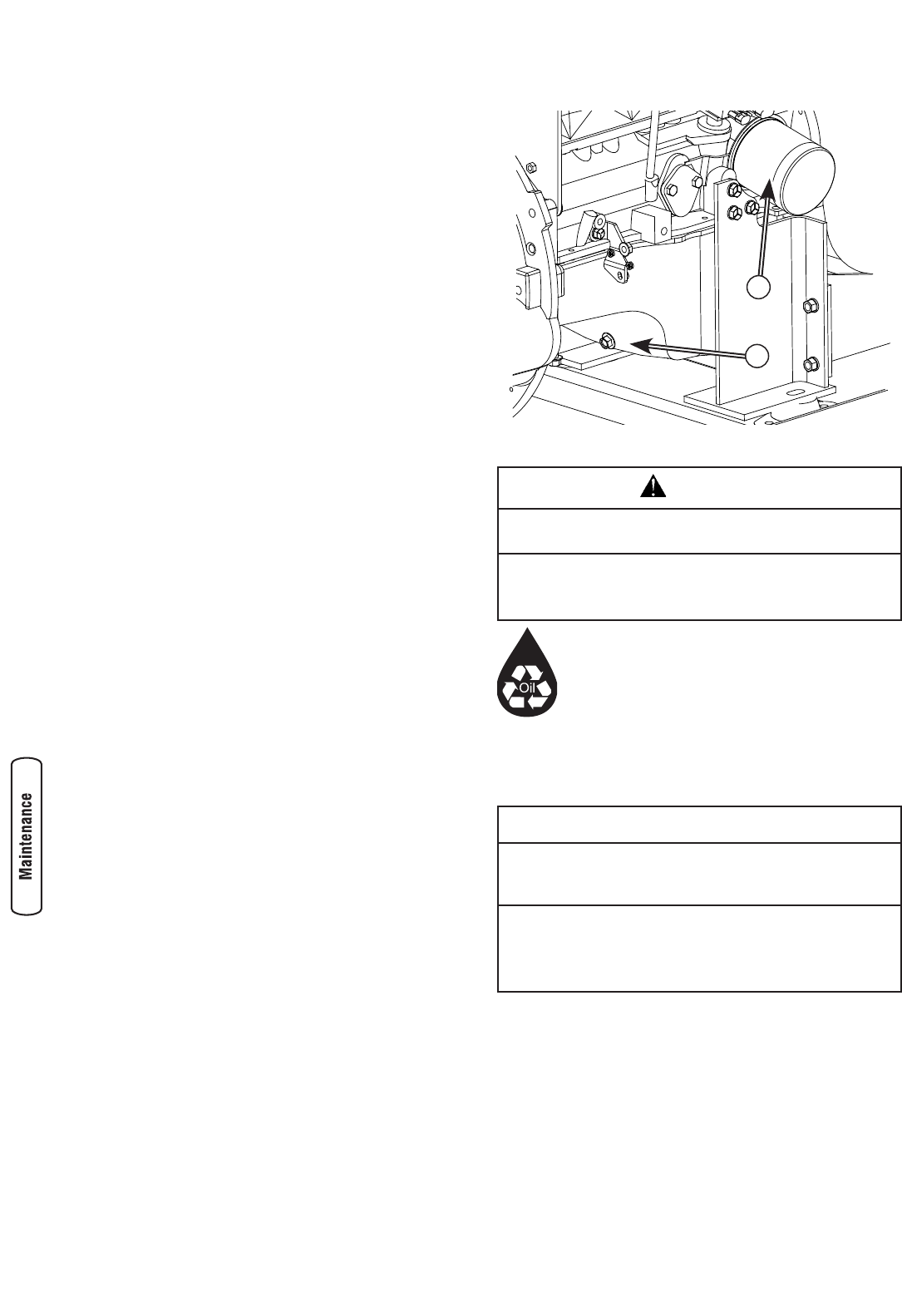

Shown here is the oil drain location (B) and the oil filter (A).

Changing Engine Oil

CAUTION

Avoid prolonged or repeated skin contact with used

motor oil.

Used motor oil has been shown to cause skin cancer in

certain laboratory animals.

Thoroughly wash exposed areas with soap and water.

•

•

KEEP OUT OF REACH OF CHILDREN. DON’T

POLLUTE. CONSERVE RESOURCES. RETURN

USED OIL TO COLLECTION CENTERS.

1. Disconnect the negative battery terminal from battery.

2. Change oil while the engine is still warm from running,

as described in the engine operator’s manual.

NOTICE

Any attempt to crank or start the engine before it has been

properly serviced with the recommended oil will result in

equipment failure.

Refer to Maintenance and engine manual for oil fill

information.

Damage to equipment resulting from failure to follow this

instruction will void engine and generator warranty.

•

•

To fill your engine with oil:

Follow the oil grade recommendation and oil fill instructions

given in the engine operator’s manual.

To make the task of adding oil more convenient, we

recommend use of a funnel attached to a length of tubing

long enough to reach from the Coolant Fill door to the oil fill

opening on the engine valve cover.

A

B