MAINTENANCE

17

Clean and inspect the spark arrester as follows:

• Remove spark arrester screen for cleaning and inspection

(Figure 13).

• Inspect screen and replace if torn, perforated or

otherwise damaged. DO NOT use a defective screen. If

screen is not damaged, clean it with commercial solvent.

• Reattach spark arrester screen to muffler.

Servicing Spark Plug

Change the spark plug every 100 hours of operation or

once each year, whichever comes first.This will help your

engine to start easier and run better.

1. Clean area around spark plug.

2. Remove and inspect spark plug.

3. Check electrode gap with wire feeler gauge and set

spark plug gap to 0.030 inch (0.76mm) if necessary

(Figure 14).

4. Replace spark plug if electrodes are pitted, burned or

porcelain is cracked. Use a recommended replacement

plug.

5. Install spark plug and tighten firmly.

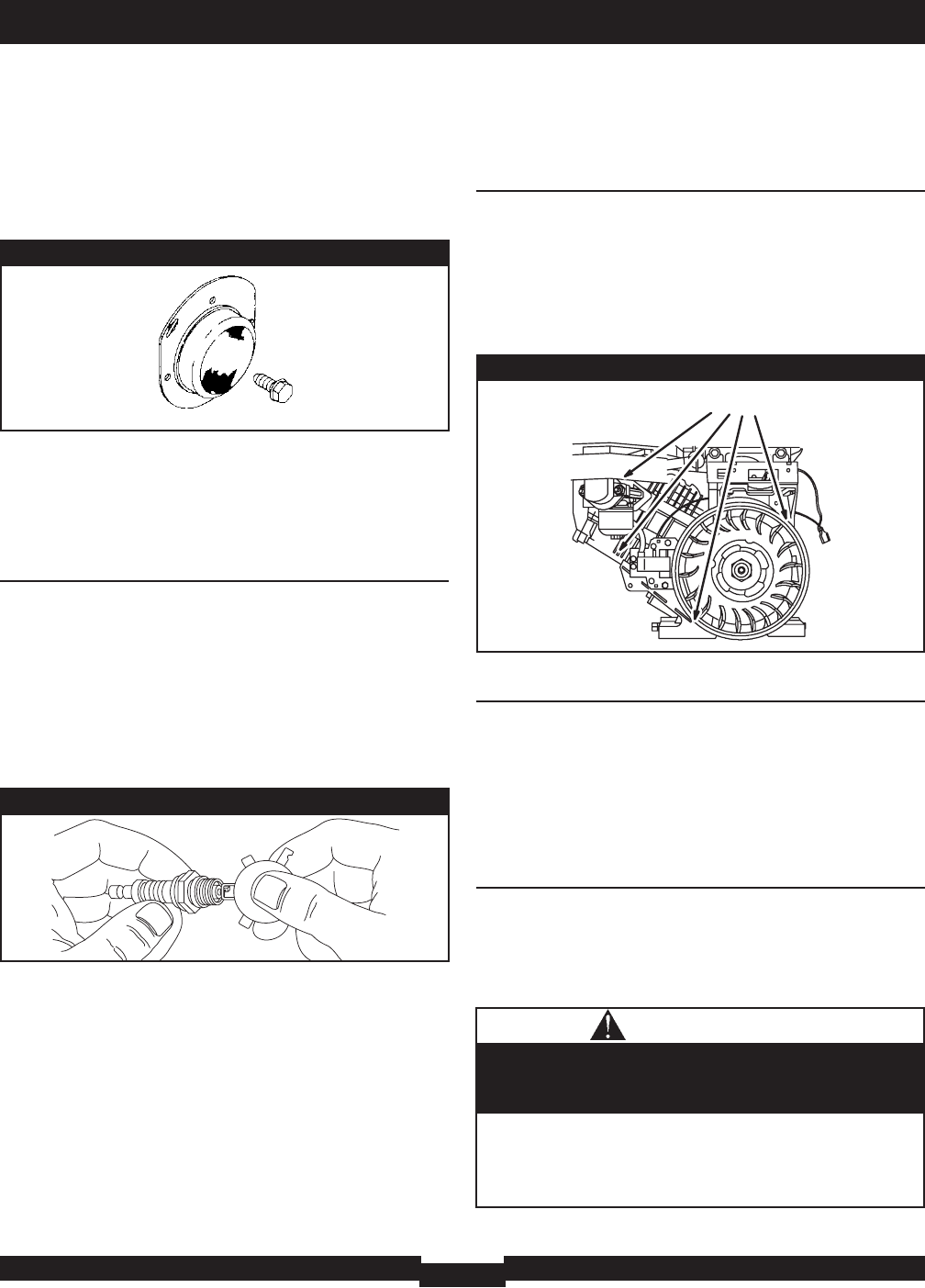

Clean Cooling System

Over time debris may accumulate in cylinder cooling fins

and cannot be observed without partial engine disassembly.

For this reason, we recommend you have a authorized

service dealer clean the cooling system (Figure 15) per

recommended intervals (see “Maintenance Schedule” on

page 14). Equally important is to keep top of engine free

from debris. See “Generator Cleaning”.

Check Valve Clearance

Regular valve clearance check and adjustment will improve

performance and extend engine life.This procedure cannot

be done without partial engine disassembly and the use of

special tools. For this reason we recommend that you have

an authorized service dealer check and adjust valve

clearance at recommended intervals.

Carburetor Adjustment

The carburetor on this engine is low emission. It is

equipped with a non-adjustable idle mixture valve and

governed idle, if equipped. Governed idle and top speed

have been set at the factory. If adjustment is required, see a

authorized service dealer.

• DO NOT tamper with governed speed. Generator supplies

correct rated frequency and voltage when running at governed

speed.

• DO NOT modify generator in any way.

Excessively high operating speeds increase risk of injury

and damage to generator.

Excessively low speeds impose a heavy load.

CAUTION

Figure 15 — Air Cooling System

Clean

Figure 13 - Spark Arrester

Typical Spark

Arrester Shown

Figure 14 — Service Spark Plug