633GC OPERATOR’S MANUAL

22

© 2007 ICS, Blount Inc. P/N 70944 Jan 07

SPARK PLUG

• A worn or fouled spark plug can cause a loss of power,

difficulty starting or rough idle (Figure 3).

• If the spark plug is dirty, clean it with a wire brush and check

the electrode gap. Readjust if necessary.

The correct gap is .020” (0.50mm).

• The spark plug should be replaced after 40 hours of operation

or earlier if the electrode is badly corroded.

• Always use the recommended spark plug type. Using the

wrong spark plug can severely damage the piston and cylinder

(Champion RCJ7Y).

Figure 3

MAINTENANCE

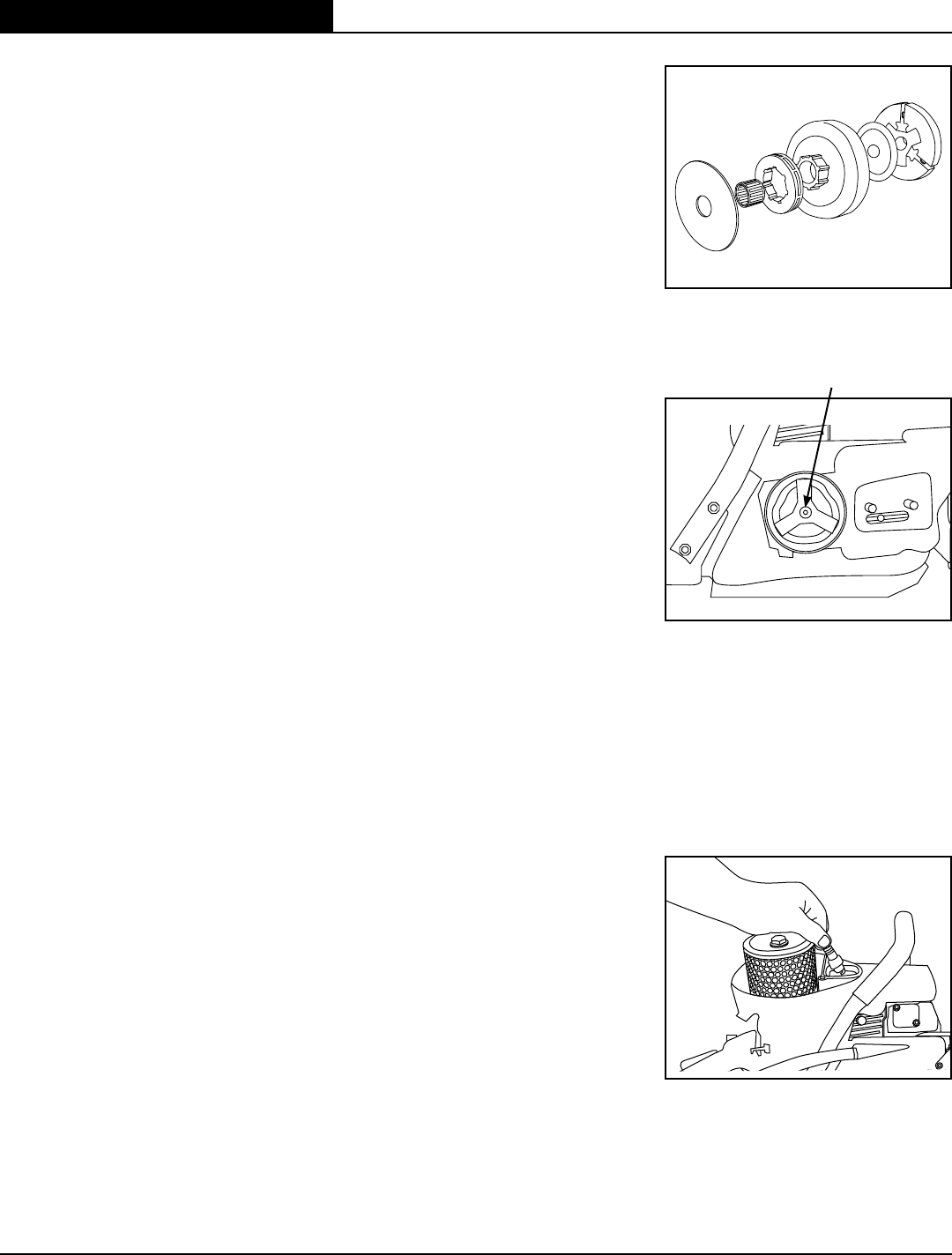

DRIVE SPROCKET INSTALLATION

• Slide the rim sprocket onto the splined adapter, either side out.

• Apply a liberal amount of grease to the needle bearing.

• Place the thin metal washer onto drive shaft. Slide the needle

bearing and clutch cup w/rim sprocket onto shaft (Figure 1).

• Install the clutch by turning it counter clockwise on the drive

shaft and firmly tighten. Replace the clutch slurry shield.

Installation of drive sprocket assembly is now complete.

• The needle bearing on the drive shaft has to be greased

regularly (daily). Use high quality water-resistant bearing

grease.

• Bearing Tip: It is not necessary to remove the clutch cup to

grease the bearing. There is a channel that goes directly from

the drive shaft to the bearing (Figure 2). Simply inject grease

directly into the end of the drive shaft.

Figure 1

Figure 2

Grease hole