Part No 430316 Form No F062006C

12

QB554HC Owner’s Manual

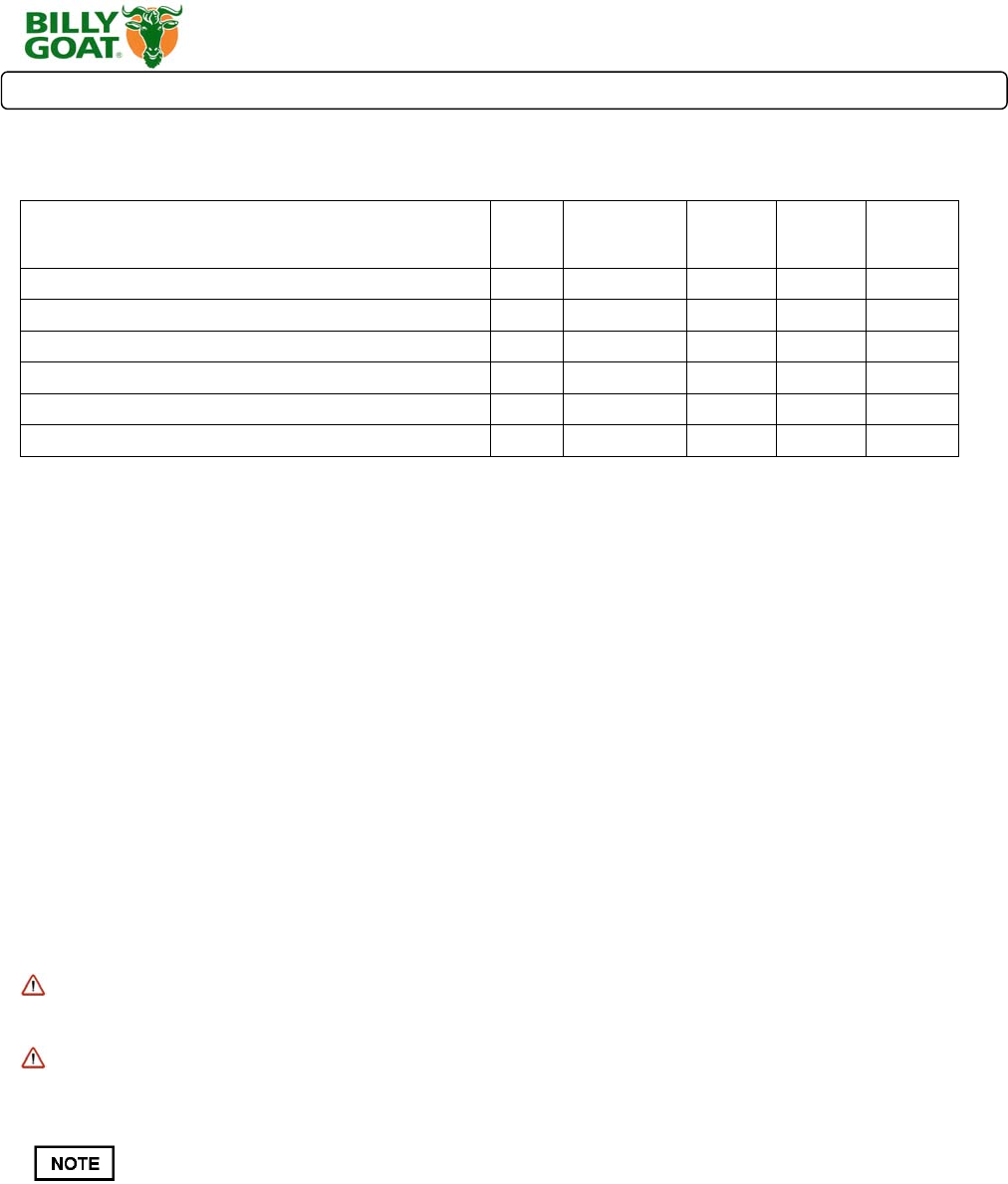

MAINTENANCE

P

ERIODIC MAINTENANCE

Periodic maintenance should be performed at the following intervals:

Maintenance Operation Every

Use

Daily or Every

5 Hours

Every 25

Hours

Every 50

Hours

Every

100-150

Hours

Inspect for worn or damaged parts.

z

Check for excessive vibration

z

Inspect Impeller for cracks or damage

z

Engine (See Engine Manual)

z

Lubricate wheels

z

Inspect for loose parts.

z

IMPELLER REMOVAL

1. Wait for engine to cool and disconnect spark plug.

2. Remove front wheel (item 23),and front wheel bracket (item 27).

3. Remove housing front plate (item 4), by removing nine (9) screws (item 12), around outside of front plate.

4. Remove impeller bolt and lock washer.

5. Pull on center hub backplate area only of impeller. If impeller slides off freely, proceed to (step 8).

6. Place two crowbars between center hub backplate area of impeller and housing on opposite sides. Carefully pry

impeller away from engine until it loosens. Using a penetrating oil can help loosen a stuck impeller.

7. If the impeller does not loosen, obtain a 1” (25.4mm) longer bolt of the same diameter and thread type as the

impeller bolt. Thread longer bolt by hand into the crankshaft until bolt bottoms. Using a suitable gear or wheel puller

against the bolt head and the impeller back-plate (near the blades), remove impeller from shaft.

8. Reinstall new impeller in reverse order of removal.

9. Tighten impeller bolt. Torque impeller bolt (see parts list on page 15 for proper impeller bolt torque

specifications).

TIRE AIR PRESSURE

Check at regular intervals and maintain.

Front Tires - 50 Psi (344 kPa).

Rear Tires - 24 Psi (165 kPa).

STORAGE

Never store engine indoors or in enclosed poorly ventilated areas with fuel in tank, where fuel fumes may reach

an open flame, spark or pilot light, as on a furnace, water heater, clothes dryer or other gas appliance.

If engine is to be unused for 30 days or more, prepare as follows:

Remove all gasoline from carburetor and fuel tank to prevent gum deposits from forming on these parts and

causing possible malfunction of engine. Drain fuel outdoors, into an approved container, away from open flame. Be

sure engine is cool. Do not smoke. Run engine until fuel tank is empty and engine runs out of gasoline.

Fuel stabilizer (such as Sta-Bil

TM

) is an acceptable alternative for minimizing the formation of gum

deposits during storage. Add stabilizer to gasoline in storage container or fuel tank. Follow

stabilizer manufacturer’s instructions to determine proper mix ratio. Run engine at least 10

minutes after adding stabilizer to allow it to reach carburetor.