2. Replacement of the cooling liquid

2. Push the valved fitting of the filled tube into the Inlet ’IN’ ofthe coolingcircuit. Ensure theloose endof the tuberemains immersed

in the liquid.

3. First, immerse the loose end of the other tube into the a bottle filled with a little liquid, to prevent the inlet tube from draining, and

next push the valved fitting into the Outlet ’OUT’ of the cooling circuit.

4. Switch on the projector. After projector boot-up procedure, the internal pump will automatically start sucking-up the fresh liquid

supply and expelling aged liquid into the empty bottle.

5. Timely switch Off the projector to prevent the fresh liquid level dropping below the free tube inlet. This again to avoid unwanted

air being sucked into the cooling loop.

6. Continue with the procedure for expelling unwanted air.

2.3 Expelling of any unwanted air

Expelling of any unwanted air

1. Close the vane, if not yet closed.

2. Put the free tube inlet of the tube connected to the ’OUT’ outlet into the remaining fresh liquid.

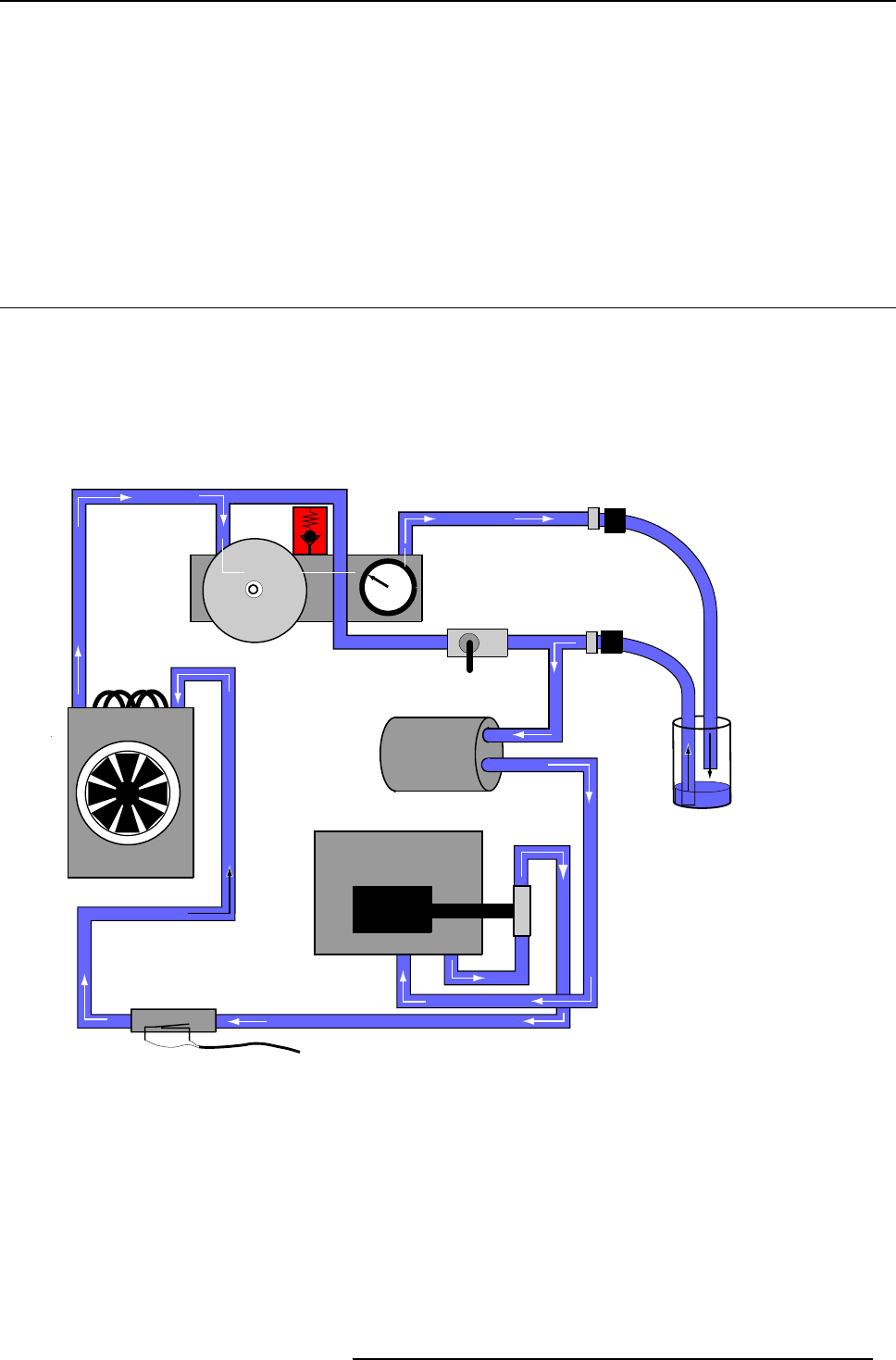

The liquid cooling loop - Expelling air bubbles

Engine

Pump

Vane

Outlet

Inlet

Expansion Vat

Manometer

Waterflow Sensor

Heat

Exchanger

to SMPS Control

Light Pipe

entry

Pressure relief

valve (3 Bar)

Image 2-4

Unwanted bubbles expelling (principle)

R59770032 COOLING LIQUID REFILL 24/08/2006 7