7 - 35

7.2 GEAR TRANSAXLE REMOVAL

(PEERLESS)

1. Place the unit on a flat surface and remove the

negative lead from the battery and remove the

spark plug lead from the spark plug.

2. Raise and support the rear of the unit. Remove the

rear wheel with associate hardware.

3. Remove the rear tailboard from the unit. Engage

the parking brake and remove the main drive belt

from the input sheave on top of the transaxle.

4. Release the parking brake and remove the brake

rod from the transaxle brake arm.

5. Remove the shift link ball joint from the shift arm.

6. Support the transaxle and remove the mounting

hardware and lower the transaxle out of the frame.

7.3 TRANSAXLE TEARDOWN

This unit contains an aluminum tag showing the model

number.

The following steps will need to be taken prior to

disassembly.

1. Clean the outside surface of the transaxle.

2. Position the shift lever in the neutral position.

3. Remove the set screw, spring and index ball.

4. Remove the neutral start switch.

5. Remove the hex head screws that hold the cover

to the case.

6. Push the shift lever rod while pulling cover off of

the case. The shifting lever may temporarily remain

in the case. Lift off cover.

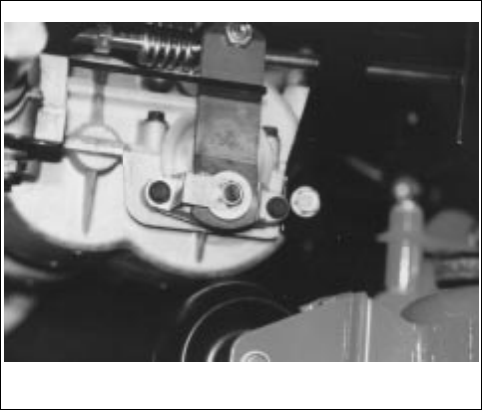

7. Remove the two brake bracket screws and remove

the brake assembly.

8. Remove the oil from the unit prior to removing the

gear shaft assemblies.

9. Remove the top bearing block on the bull gear of

the differential. Remove the bull gear, bevel pinion

gears with center shaft and the axles.

There are 3 shaft assemblies in this transaxle: the

output shaft, the countershaft, and the shifter/brake

shaft assembly. Remove these assemblies as

complete as possible from the case.

As these assemblies are taken apart, lay the parts out

in a systematic order. This will help to make

reassembly easier and inspection of all parts possible.

Clean each part as the parts are laid out.

The input shaft can also be removed and inspected or

serviced. Remove the snap ring on the bevel gear and

pull the shaft through the case. The square cut "O" ring

must be replaced if the shaft is removed.

Tecumseh tool part No. 670251, is used for removal

and installation of needle bearings for the input shaft.

The needle bearing on the inboard side is installed

.135-.150" below flush.

Reassembly

1. Apply grease between the bearings in the cover

and install the input shaft, bevel gear and snap

ring.

2. Oil both keyways and slide keys and collar on the

shifter/brake shaft.

NOTE:

Assemble the countershaft and the shifter/

brake shaft. Match them together and place into the

housing as a single unit.

Figure 42