7 - 28

Check the oil level after fully purging the unit of air. It

should be between 1.25" and 1.62" (3.175-4.11 cm)

from the top of the housing.

After installing the IHT, make sure all linkages and

actuators and functioning properly.

7.6 HYDRO-GEAR TRANSMISSION

REMOVAL

1. Place the unit on a flat surface and remove the

negative lead from the battery and the spark plug

lead from the spark plug.

2. Remove key and spark plug wire.

3. Raise and block the unit frame on jack stands

behind of the transaxle in the frame.

4. Remove the rear wheels by removing the lug nuts

holding the wheels to the axle hub.

5. Release the transmission belt tension spring and

remove the transmission belt from the input sheave

on top of the transaxles.

6. Release the parking brake control rod on the top of

the units frame by pulling the hair pin and releasing

the tension spring.

7. Tighten the shifting cam friction pack lock nut to

hold the transaxle neutral position.

8. Remove the cap screw, flat washer and locknut on

the shift rod and remove the shift rod ball joint from

the transaxle cam arm.

9. Do not remove or loosen the hardware on the

transaxle sub-frame at this point.

10.Support the transaxles subframe with a floor jack

from the rear of the tractor.

11.Remove the rear anchor strap from the transaxle

subframe and the rear of the unit.

12.Remove the two right and left front anchor bolts

holding the transaxle subframe to the tractor frame

and remove the two rear anchor bolts from the left

and right side holding the transaxle subframe to

the units frame and lower jack.

13.With the transaxle assembly removed from the

units frame, place the axle assembly on a flat work

surface.

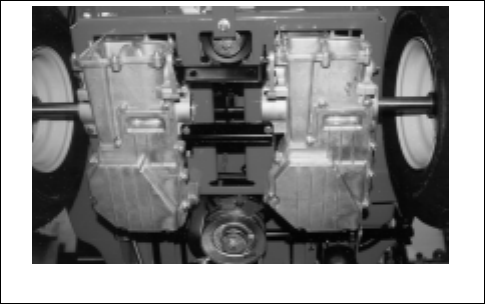

7.7 HYDRO-GEAR TRANSMISSION

INSTALLATION

Before installing the transaxle assembly into the tractor

frame with the axle subassembly installed, the

following items will need to be done.

1. Make sure the brake rod has two flat washers and

a heavy coil spring installed on it before inserting

the transaxle into the tractor frame.

Do not tighten any hardware until all the support

hardware is installed.

2. When all the hardware is in place, tighten to the

appropriate torque according to the hardware

torque chart.

3. Install the two flat washers, compression spring

and hair pin on the rear of the brake rod which

return/release the brake arm.

4. Install the cap screw, flat washer and lock nut on

the shift rod ball joint securing it to the transaxle

shift cam.

5. Install the transmission drive belt on the transaxle

input sheave and check the belt routing on the idler

arm and engine pulley and install idler arm tension

spring.

6. Install the dump valve rod and attach the ball knob.

7. Install the rear wheel with the lug nuts removed

earlier.

Transaxle Neutral Adjustment

1. Make sure that the rear of the unit is suspended

before the unit is started.

2. Make sure that the interlock system is operational

before proceeding.

3. Place a weight onto the seat to activate the seat to

activate the seat switch.

4. Unbolt tie rod from transaxle flange.

5. Start engine and observe wheel motion.

6. Turn transmission cam until wheel stops turning.

Tighten cam locking nut. Stop unit and connect

linkage.

7. Adjust to proper length. Unlock cam locking nut

and start engine. Test for creep. Repeat if needed.

8. If neutral adjustment is needed refer to

Neutral

Adjustment

section.

Figure 28