4 - 13

4.10 NEUTRAL ADJUSTMENT (SPEED

CONTROL)

1. Stop the engine. Remove the ignition key. Push the

PTO knob into the "OFF" position.

2. Place jack(s) under rear transaxles only. If jack(s)

are not available, place support blocks under both

transaxles at the rear of the unit to raise the rear

wheels off the ground.

3. Remove side shrouds.

4. Place a weight on the seat to close the seat switch.

Start the engine and run it at part throttle.

5. Remove the connecting linkage from the flange

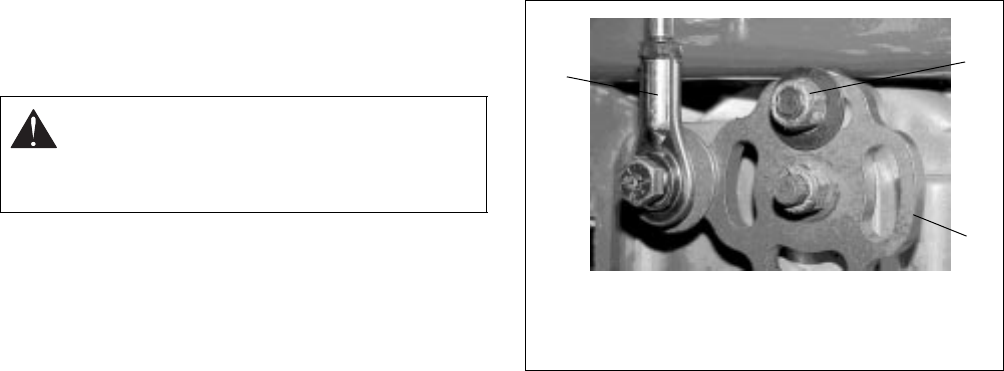

bushing, Figure 12.

6. Rotate flange bushing until the wheel stops

rotating.

7. Lock the flange bushing in place by tightening the

lock nut.

8. Adjust the connecting rod length and reattach it to

the flange.

9. Loosen the lock nut and test by moving the

steering control levers.

10.Repeat procedure for the other side of the unit.

11.Reinstall side shrouds.

If the drive cannot be adjusted to neutral using the

above procedure, the link to the flange on the transaxle

can be adjusted.

1. With the rear of the unit jacked up and supported,

remove the connecting linkage at the flange

(Figure 11).

2. Place a weight on the seat and start the engine.

Run it at part throttle.

3. Rotate the flange until the wheel stops turning and

tighten the lock nut.

4. Shut off the engine.

5. Loosen the lock nut on the connecting linkage and

adjust the rod end to match the hole in the flange.

6. Reattach the connecting linkage and tighten the

lock nut to the rod end.

7. Loosen the flange lock nut and test.

4.11 ADJUSTING THE UNIT TO TRACK

STRAIGHT

The primary reason the unit may not track straight is

incorrect or unbalanced tire air pressure.

1. First, check and adjust the tire pressure.

2. With tire pressures equal and the rear of the unit

on jack stands, check the circumference of the tire.

If one tire is larger than the other, increase

pressure in the small tire and/or decrease pressure

in the larger tire.

3. With both tires the same size, set the control

handles. The roller bearing on the speed control

arm must be in the neutral position on the neutral

detent strap.

4. Adjust upper control arm linkage until the control

handles will enter the neutral switch slot and

activate the neutral switches.

5. Tighten locking nuts on the control linkage.

6. Disconnect linkage from the transmission, loosen

two cap screws in the speed control arm and

position pump weldment in the horizontal position

and tighten cap screws.

7. Start unit and by hand adjust the transmission

control cam until neutral is found.

8. Tighten a transmission locking nut.

9. Stop engine.

10.Set transmission linkage rod, then line up with hole

in control cam and install and tighten attachment

ball.

11.Loosen the transmission control locking nut.

12.Start unit and check tracking.

CAUTION:

PREVENT personal injury!

ALWAYS MAKE CERTAIN that jack(s) or

blocks used are stable, strong and will

support the weight of the unit.

1. Connecting Linkage

2. Lock Nut

3. Flange

Figure 11

1

2

3