GB - 21

4. Remove belt finger by removing cap

screws mounting belt finger to engine

(Figure 20 or Figure 21).

5. Remove attachment drive belt from

engine sheave (it may be necessary to

turn engine sheave using recoil starter

handle).

IMPORTANT: To avoid bending bottom cover,

when tipping unit apart, support handlebars

firmly or tip unit up on housing and remove

bottom cover by removing six cap screws

before separating unit.

6. Support the frame and housing.

7. Remove hex bolts securing housing to

frame (two on each side). Tip housing

and frame apart on pivot pin.

8. Remove attachment drive belt from

attachment pulley (hold brake away from

belt).

Replace Attachment Drive Belt

1. Place new belt onto attachment pulley.

NOTE: Holding down the attachment clutch

lever will make it easier to reconnect the

housing and frame.

2. Tip housing and frame back together

and secure with hex bolts.

3. Place belt onto engine sheave.

4. Replace belt finger.

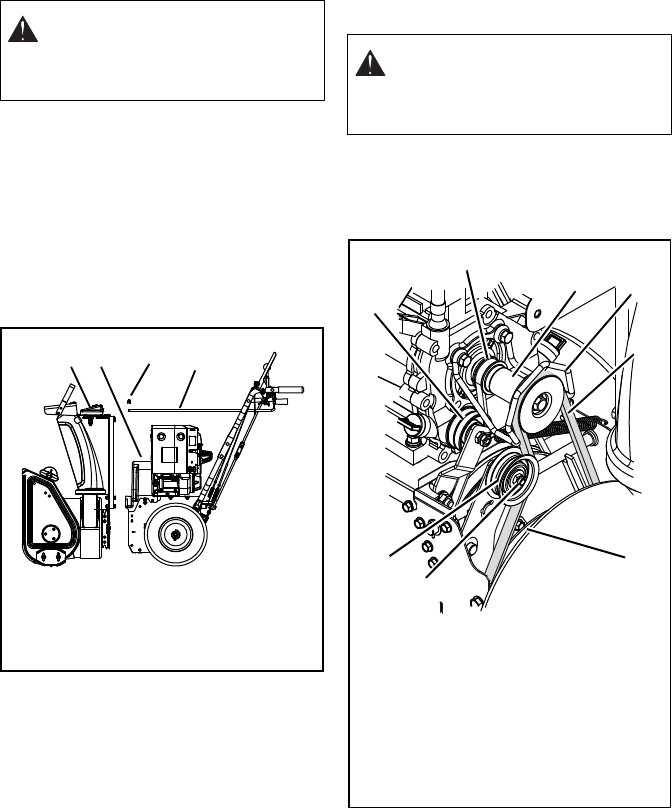

IMPORTANT: With the clutch lever engaged,

the belt finger located opposite the belt idler

must be less than 1/8 in. (3,2 mm) from the

belt, but not touching the belt, or belt

grabbing may occur causing impeller to rotate

while the attachment clutch is disengaged

(Figure 21).

5. Adjust clutch per Attachment

Clutch/Brake Adjustment on page 23.

6. Replace chute crank and secure with

spring pin.

7. Run in the attachment belt. See Run-in

Attachment Belt on page 10.

8. Replace belt cover.

CAUTION: Always support the unit

frame and housing when loosening

the cap screws holding them

together. Never loosen cap screws

while unit is in service position.

Figure 19

OS8062

1

2

3

4

1. Pinion Gear

2. Belt Cover

3. Spring Pin

4. Chute Crank

WARNING: AVOID INJURY. Auger

must stop within 5 seconds when

attachment lever is released or

serious injury or unit damage may

result.

Figure 20

OS8160

5

3

2

1

6

7

4

1. Traction Belt

Idler

2. Traction Drive

Belt

3. Engine Sheave

4. Belt Finger

5. Attachment

Drive Belt

6. Attachment

Pulley

7. Attachment

Idler Nut

8. Attachment

Belt Idler

8