Installation

Procedures

Unit Inspection

Inspect your unit very carefully before

installing. Make sure there has been no

damage to the evaporator fins or there

are no punctures or oil-soaked areas on

the box. This would indicate damage to

the refrigeration system and should be

rejected immediately.

THE UNIT MUST BE TRANSPORTED IN

THE UPRIGHT POSITION AT ALL

TIMES AND MUST NOT BE DROPPED

OR TAILGATED. DAMAGE TO THE

UNIT DURING TRANSPORTATION IS

NOT THE RESPONSIBILITY OF THE

MANUFACTURER.

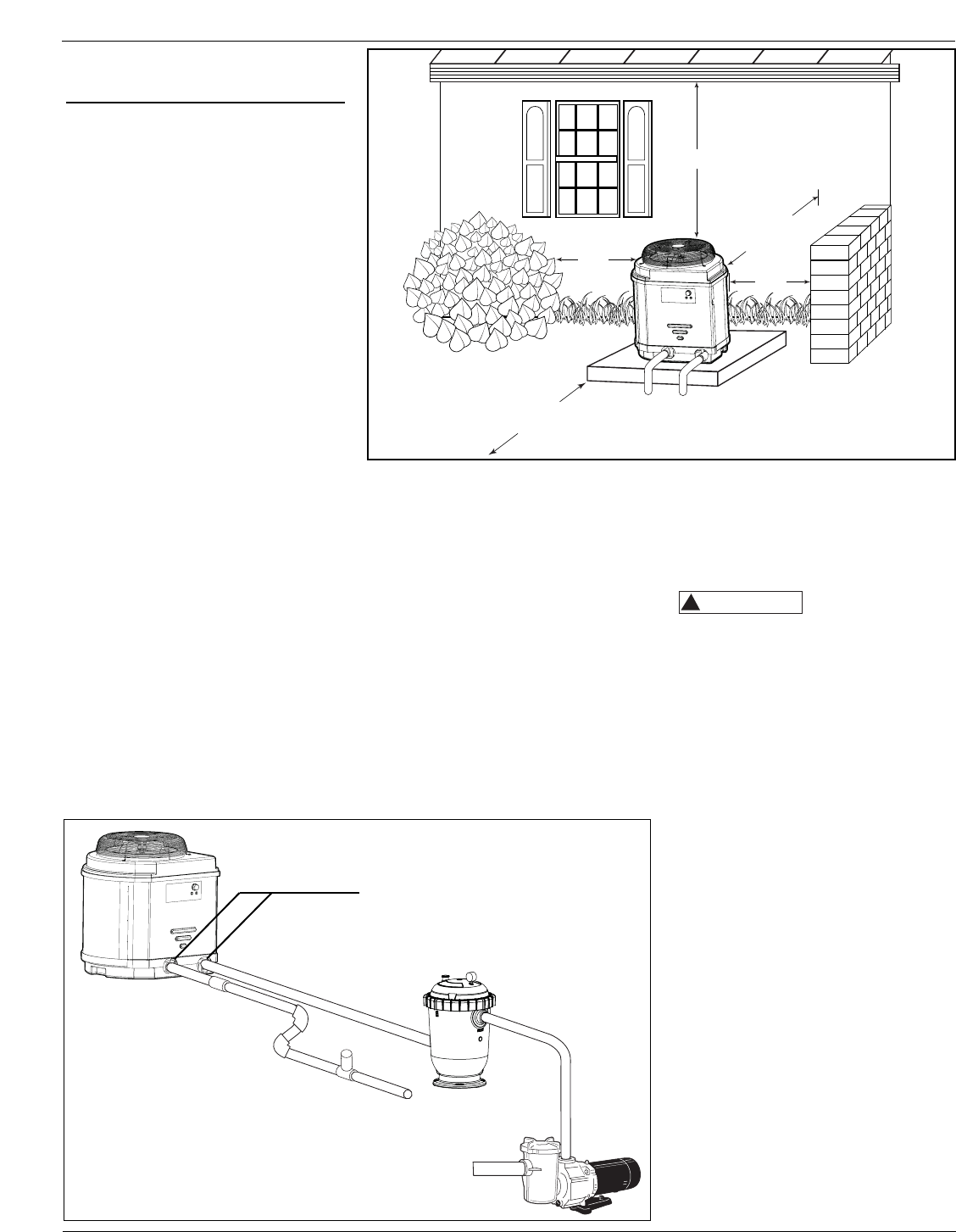

Unit Location

Once the unit has been inspected and

cleared of any transportation damage,

it is now time to locate the pool

heater. It is very important to

understand the location of the unit for

the best performance of operation.

See Figure 1 for location

recommendations.

A minimum of 18” of clearance

between the evaporator coils and

shrubs, fences, walls, etc. must be

maintained for adequate air intake.

A minimum of 5’ of vertical clearance

between the top of the unit and any

roof overhang or other obstructions

must be maintained in order to

prevent the re-circulation of cold air

back into the evaporator coils. This is

to maintain the efficiency of the unit.

A minimum of 36” of clearance

between the front of the unit (access

panel area) and any obstruction must

be maintained to allow maintenance

on the unit when necessary.

The unit should be located on a solid

level surface, a minimum of 36”x 36”

for proper drainage.

Make sure any sprinkler heads are not

directly spraying water on the unit.

While heat pumps are made for an

outdoor environment, they are not

designed to have sprinkler water

constantly spraying them. NOTE: This

type of constant watering directly

on the unit can void your warranty.

Condensation drain holes are provided

3

in all units for adequate removal of

condensation and rainwater. ALL

UNITS WILL HAVE CONDENSATION.

THIS SHOULD NOT BE MISTAKEN

FOR A LEAK IN THE UNIT.

Plumbing

Where freezing weather is encountered,

the detachable connection/union

(provided on PRO1000) must be installed

immediately adjacent to the heater to

facilitate servicing and draining of the

heat exchanger. Draining is necessary

to prevent damage to the condenser

shell and coil due to the expansion

of freezing water.

The minimum water circulation

capacity flowing through the pool

heater is 25 gallons per minute and the

maximum capacity is 80 gallons per

minute.

Do not install a water shutoff valve in

the piping from the outlet of the pool

heater to the pool or spa. However, a

check valve that does not include a

shut-off feature may be installed for

convenience during servicing.

A check valve or Hartford Loop is

recommended between the unit and a

chlorinator. The chlorinator must be

downstream of the heat pump. Failure

to do so may void the warranty.

If you have an in-floor cleaning system,

please take note of any special

plumbing requirements to operate all

units effectively.

Figure 2 shows the recommended

installation layout.

!

CAUTION

www.aquaprosystems.com

PRO400, PRO600, PRO1000

5’ Minimum

18” Min.

18”

Min.

36”Min.

18”

Min.

Figure 1 - Unit Location

Figure 2 - Recommended installation layout

FILTER

POOL

PUMP

CHLORONATOR

WARM

WATER OUT

TO POOL

COLD WATER

IN FROM POOL

IN

OUT

CHECK

VALVE

1-877-AQUASYS

UNIONS (INCLUDED WITH PRO1000)