MAINTENANCE

HYDRO 88 & 96 03/09 Maintenance Section 5-2

©2009 Alamo Group Inc.

MAINTENANCE

Daily Checks

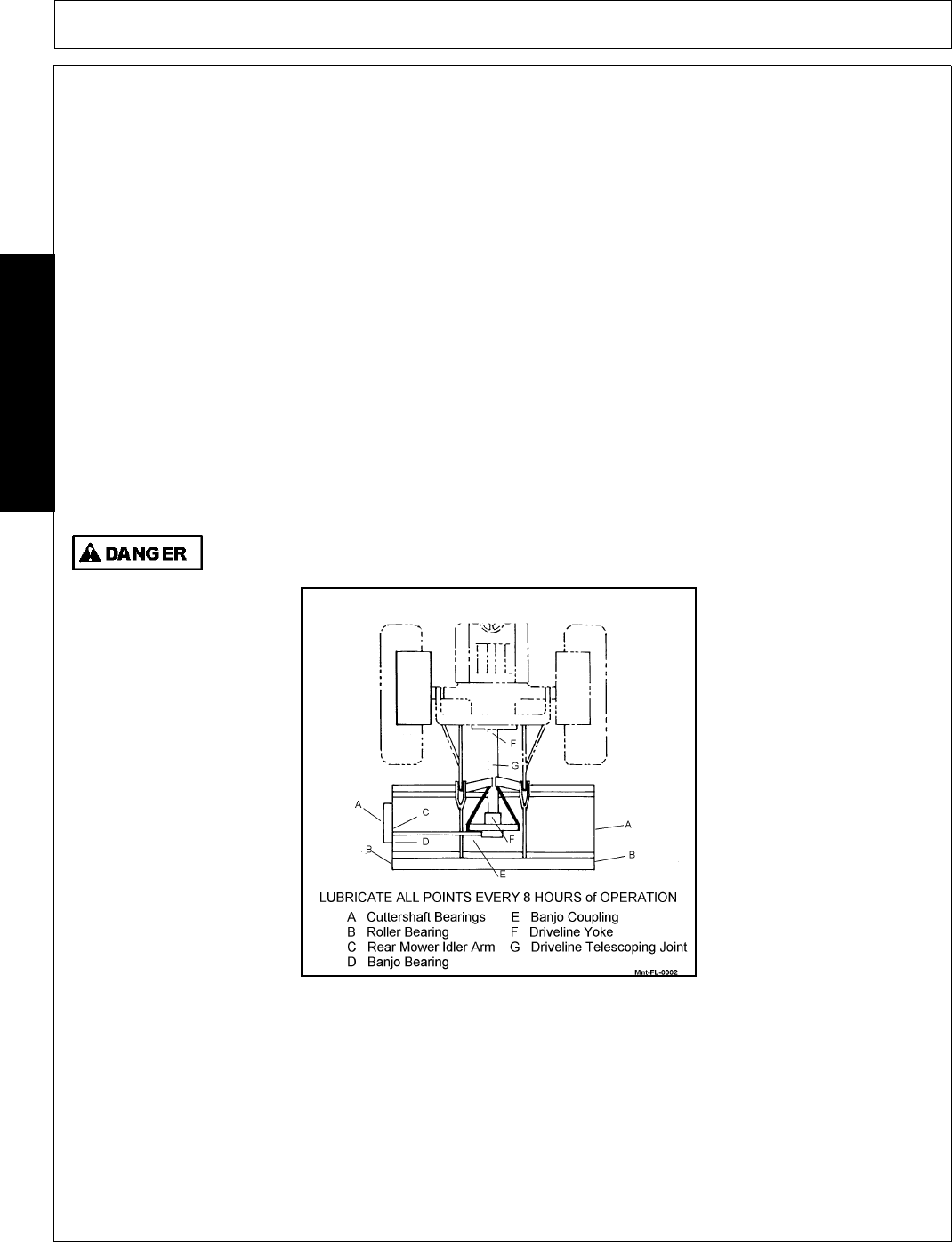

1. Lubricate at the specified intervals as outlined in the lubrication diagram below. All mower grease fittings

are equipped with lubricaps which snap over the grease fittings to prevent dirt from entering the fittings.

Remove the cap and wipe the fitting before greasing. Wipe the outlet of the grease gun then grease the

bearing. When finished, place the cap over the fitting and wipe any excess grease from around the cap. In

extremely dusty conditions, it is desirable to lubricate more often than every 8 hours. Grease the PTO shaft

as outlined on the diagram located on PTO shaft shield. The idler pulleys are equipped with a sealed ball

bearing and require no further lubrication. Caster wheel bearings should be repacked at the end of each

mowing season and checked before the start of the next season. The gearbox is shipped with the proper

amount of SAE No. 90 extreme pressure lubricant. Maintain the level of this oil at the LOWER 1/8” pipe

plug on the gearbox cover. LUBRICATE MOWER BEFORE INITIAL USE. See Figure Mnt-FL-0002 and

Pictures MntP-FL-0001, MntP-FL-0002, MntP-FL-0003, MntP-FL-0004, MntP-FL-0005, MntP-FL-0006.

Note: Lubricate flail roller bearings until lubricant can be seen coming out between roller and bearing housing.

2. Before each day’s use, follow this procedure:

A. Visually check the unit and make certain all items are properly tightened.

B. Check the cuttershaft to make certain it is fully knifed. Replace any missing knives or cotter pins, then

run the unit at full speed to check for vibrations. Do not operate the unit in an “out-of-balance” condition.

C. Check rear rubber deflector condition and replace if worn or damaged.

Before doing maintenance, turn off power and securely block up mower.

A. Cuttershaft Bearings

B. Roller Bearing

C. Rear Mower Idler Arm

D. Banjo Bearing

E. Banjo Coupling

F. Driveline Yoke

G. Driveline Telescoping Joint