MAINTENANCE

SB5/6 03/09 Maintenance Section 4-7

© 2009 Alamo Group Inc.

MAINTENANCE

HYDRAULIC SYSTEM

PUMP & MOTOR

The pump and motor is the heart of the hydraulic circuit and is vital to the performance of all Triumph mowers.

Worn pumps and motors should be replaced or repaired. It is recommended that most customers replace

when this occurs however, spare parts and seal repair kits are available for field repair if desired. ALWAYS

DRAIN, CLEAN AND REFILL THE TANK WITH CLEAN OIL when pump repairs are made.

NOTICE: To avoid possible damage to a new or rebuilt pump, run the tractor engine at very low RPM for about

5 minutes with all control levers in neutral position prior to placing in service.

VALVES

The major cause of valve malfunction is dirty oil or foreign material causing the valve spools to be scored or

seals to fail. If repairs are required remove the valve from the system and thoroughly clean all parts before

reassembly. Replacement parts and service kits are available. The valve body and spools are match fitted

and are not interchangeable or adjustable. Check the valve lever linkage for free movement to allow the

detents to locate without binding.

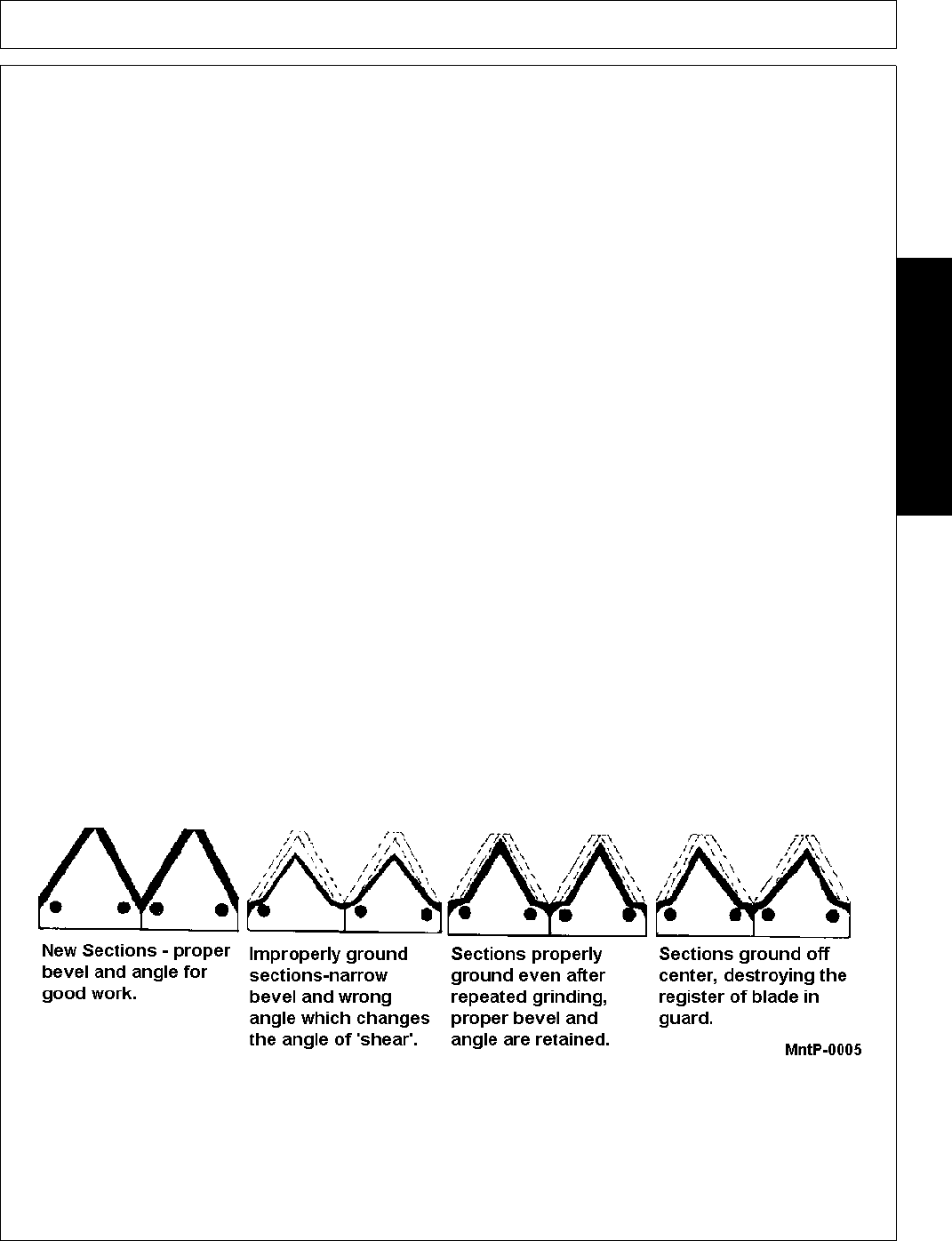

KNIFE REPAIR

ALWAYS USE A SHARP KNIFE. A dull knife cuts poorly, may plug, and doesn't do a clean job. Keep the knife

straight with the sections firmly riveted to the knife back. When sharpening the knife, be careful to restore the

original shear angle and bevel of 23 degrees. Properly and improperly ground knife sections are shown in the

Fig. MntP-0005. A knife section that has been ground several times may have the proper angle and bevel and

still be unserviceable because the hard cutting edge has been ground away and the section is too short to cut

everything encountered.

KNIFE

Replace worn or broken knife sections. Triumph knife sections are heavy duty sections made of special steel

and will stay sharp for many more hours than conventional sections.