MAINTENANCE

SB5/6 03/09 Maintenance Section 4-5

© 2009 Alamo Group Inc.

MAINTENANCE

3. Sight down the bar and look for a knife section in close contact with a guard ledger. If the section to the

right and left are both 1/8" if the ledger, DO NOT bend the two side ones up until they contact the knife.

This is WRONG! The high guard should be knocked down until all three contact. The higher up a guard

gets bent, the more the knife section will tend to contact only the tip.

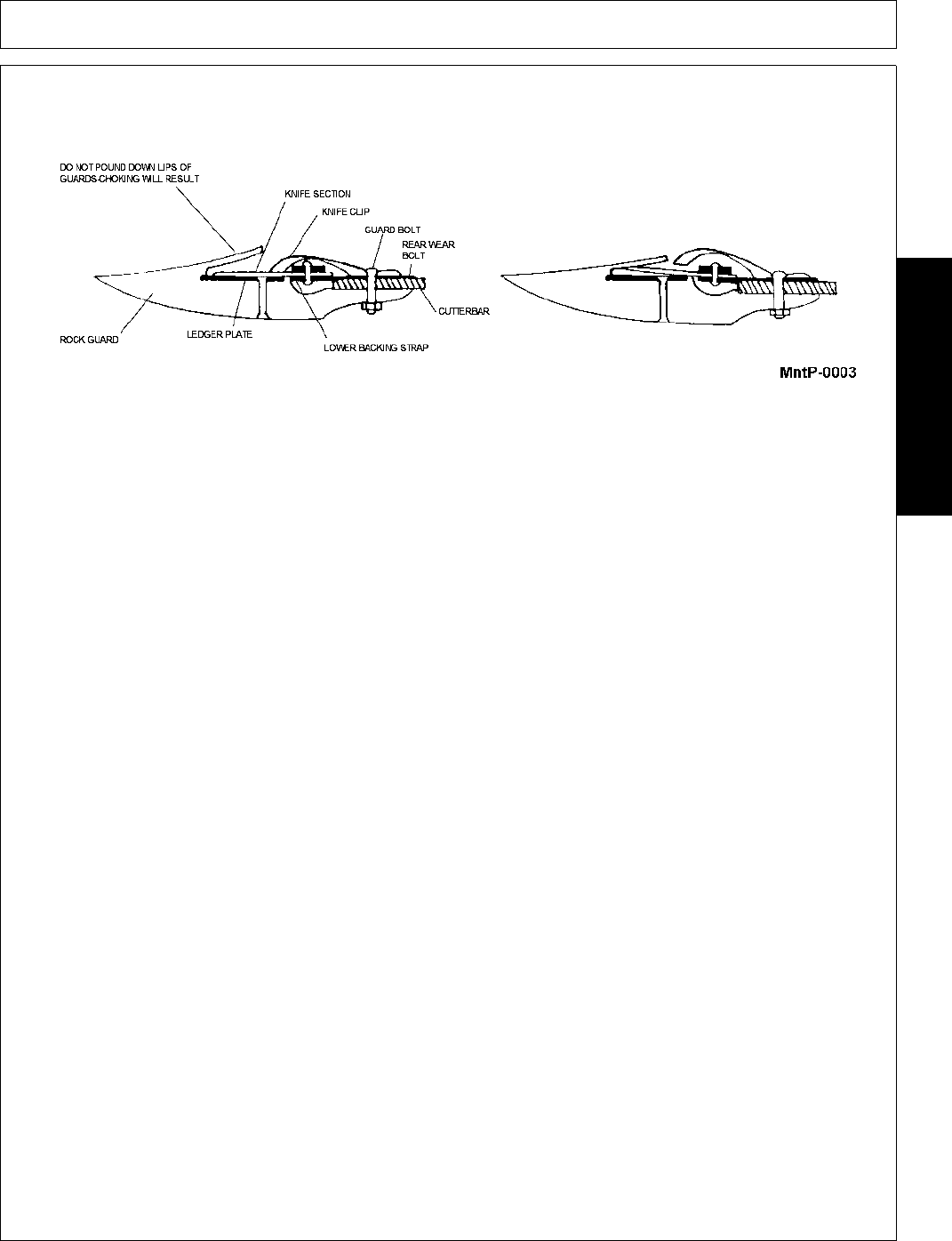

4. Bolt the guards tight and strike them at the thick part, just in front of the ledger plates. Do not pound

down the guards lips as the knife might bind. Retighten the bolts as each guard is aligned. Disregard

the position of the guard points. It is the ledger plate which must be kept in line. Blunt points should be

filed sharp.

5. Start from the inner shoe, adjust each guard so that the knife section and ledger are parallel and

reasonably close to each other. Find the high guard and knock them down. Usually, the only time it is

necessary to knock a guard up is when new guards are first installed on the bar.

6. Make certain that the first knife section is contacting the inner shoe ledger plate. If it doesn't contact,

check the first or second guard which may be holding the knife up or the inner shoe ledger plate may

be worn out.

7. Finally, align the industrial outer shoe in the same way as guards.

WEAR PLATE

The wear plates must line up with each other to give the knife back straight bearing along its entire length.

Wear plates should project approximately 1/16" in front of the leading edge of the cutter bar after adjustment.

Triumph wear plates are hardened on both edges. After the first edge has worn back, simply turn over the plate

to obtain a new wearing surface.

CLIPS

After all guards are adjusted, it is necessary to see that the knife clips are bent down to within 1/64" of the

section. The easiest way to check this is to hold the knife down on the ledger plate and use a feeler gauge or

the cover of a matchbook to measure the clearance. Do not attempt to hold the knife tightly against the ledger

plate with the clips. Knock the clips down with a hammer. A light blow is all that is required. If the clips drag on

the knife, pry them up. Drag will bind the knife and wear out the clip very rapidly. See Image MntP-0004