20

9. Maintenance

■ BLADES (MA1)

•When refilling the tank or resting, it is often a

good idea to use the time to oil the cutting

blades.

• If a gap exists between the upper and lower

blades, follow the procedure below to adjust

them so that they fit more closely together.

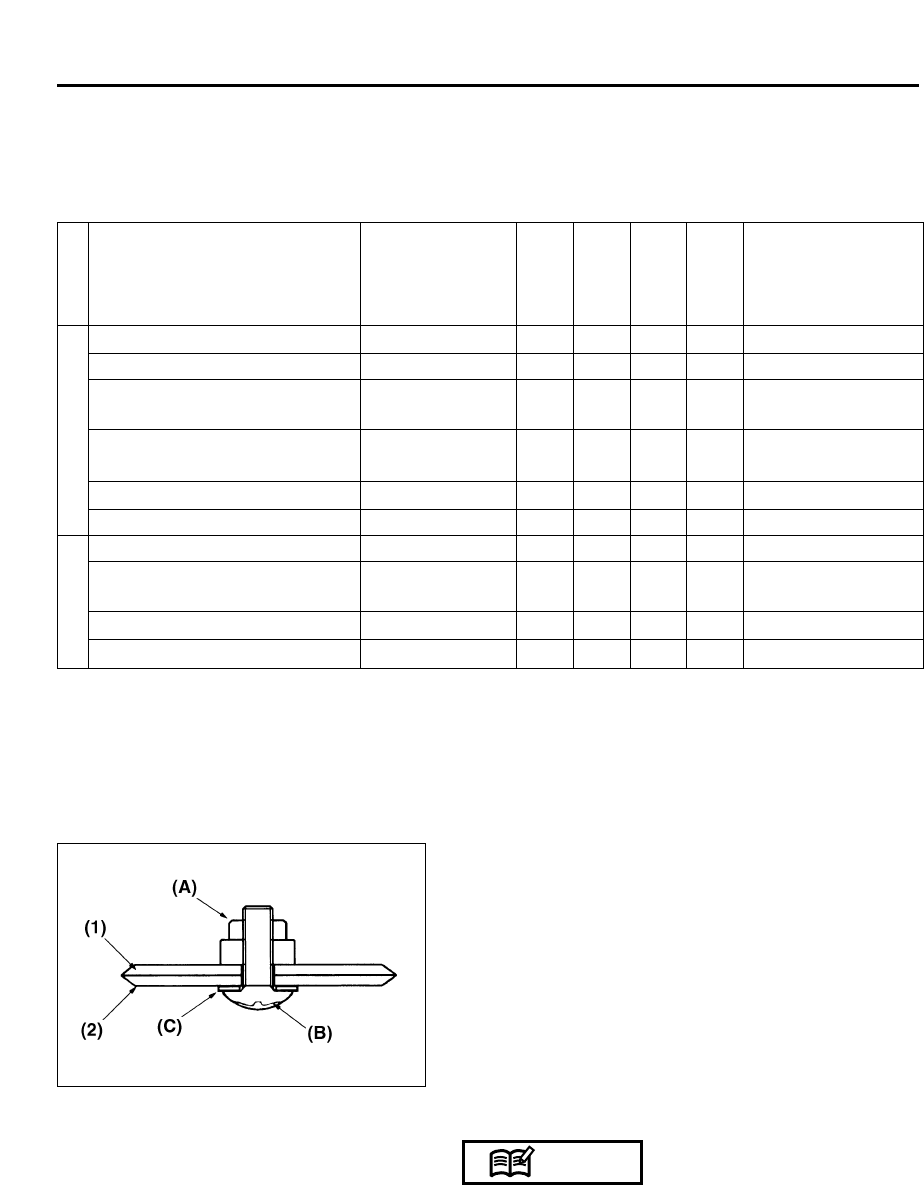

1. Loosen lock nut (A) as shown in the diagram.

2. Tighten screw (B) fully, and then turn one-third

to one-half of a rotation backward.

3. While holding onto the screw to keep it in

position, tighten the lock nut.

4. Check to make sure that the flat washer (C) is

loose enough so that it may be turned by

pressing on it with a finger.

(1) Upper blade (2) Lower blade

Screwing in the screw too tightly may make it

impossible for the blades to move. Conversely, not

screwing in the screw tightly enough may make the

blades of the trimmer feel dull and cause leaves

and branches to become caught in the blades of

the trimmer.

NOTE

MA1

every every every

25 50 100

system/compornent procedure before hours hours hours note

use after after after

fuel leaks, fuel spillage wipe out ✔

fuel tank, air filter, fuel filter inspect/clean ✔✔ replace, if necessary

see

■ADJUSTING

replace carburetor

idle adjusting screw ✔

IDLING SPEED (p.18)

if necessary

clean and readjust

GAP: .025in(0.6~0.7mm)

spark plug ✔

plug gap replace, if necessary

cylinder fins, intake air cooling vent clean ✔

muffler, spark arrester, cylinder exhaust port

clean ✔

throttle lever, ignition switch check operation ✔

replace if

cutting parts ✔

something's wrong

gear case grease ✔

screws/nuts/bolts tighten/replace ✔✔not adjusting screws

ENGINE

SHAFT

■ MAINTENANCE CHART

Maintenance, replacement, or repair of the emission control device and systems may be

performed by any non-road engine repair establishment or individual.