■ PROCEDURES TO BE PERFORMED

AFTER EVERY 100 HOURS OF USE

1. Remove the muffler, insert a screwdriver into

the vent, and wipe away any carbon buildup.

Wipe away any carbon buildup on the

muffler exhaust vent and cylinder exhaust

port at the same time.

2. Tighten all screws, bolts, and fittings.

3. Check to see if any oil or grease has worked

its way in between the clutch lining and

drum, and if it has, wipe it away using oil-

free, lead-free gasoline.

■ MAINTENANCE BEFORE STORAGE

• Old fuel left in the carburetor may cause

starting failure. When a series of operation

finished, make sure to empty the fuel tank

and drain the carburetor.

• Check all parts and the functions. If the

failured or damaged parts have been found,

replace them with new ones.

■ GEAR CASE

• The reduction gears are lubricated by

multipurpose, lithium-based grease in the

gear case. Supply new grease every 25

hours of use or more often depending on the

job condition.

• Remove the bolt opposit to the grease nipple

before installing new grease to arrange for

old grease to exit.

■ INTAKE AIR COOLING VENT

• Never touch the cylinder, muffler, or

spark plugs with your bare hands

immediately after stopping the engine.

The engine can become very hot when in

operation, and doing so could result in

severe burns.

• When checking the machine to make sure

that it is okay before using it, check the

area around the muffler and remove any

wood chips or leaves which have

attached themselves to the brushcutter.

Failing to do so could cause the muffler

to become overheated and that in turn

could cause the engine to catch on fire.

Always make sure that the muffler is

clean and free of wood chips, leaves, and

other waste before use.

WARNING

Specifications

7

MODEL CODE Unit BC4350FW

Overall size

Length mm 1845

Width mm 650

Height mm 560

Dry weight Kg 7.8

Engine model ✽ G45L-F

Displacement cc 41.5

Carburetor ✽ Float

Fuel (Mixture ratio) ✽ 50:1 (Gasoline and 2cycle oil)

Fuel tank capacity litter 0.8

Service range rpm 5000~8000

Spark plug ✽ Champion RCJ6Y

Clutch system ✽ Two-shoe Centrifugal-Type

Anti-vibration system

Housing ✽ Yes

Handle-bracket ✽ No

Gearhead

Neck angle deg 60

Reduction ratio ✽ 1.400

Blade rotation ✽ Counter-clockwise

Handle type ✽ Double

Throttle lever ✽ Trigger Type (With Safety-lock)

Standard cutter ✽ 2 Teeth Blade

Harness type ✽ Double

Quick release ✽ Yes

Standard accessories

Fuel-Tank ✽●

Tool-kit ✽●

Owner's manual ✽●

Specifications are subject to change without notice.

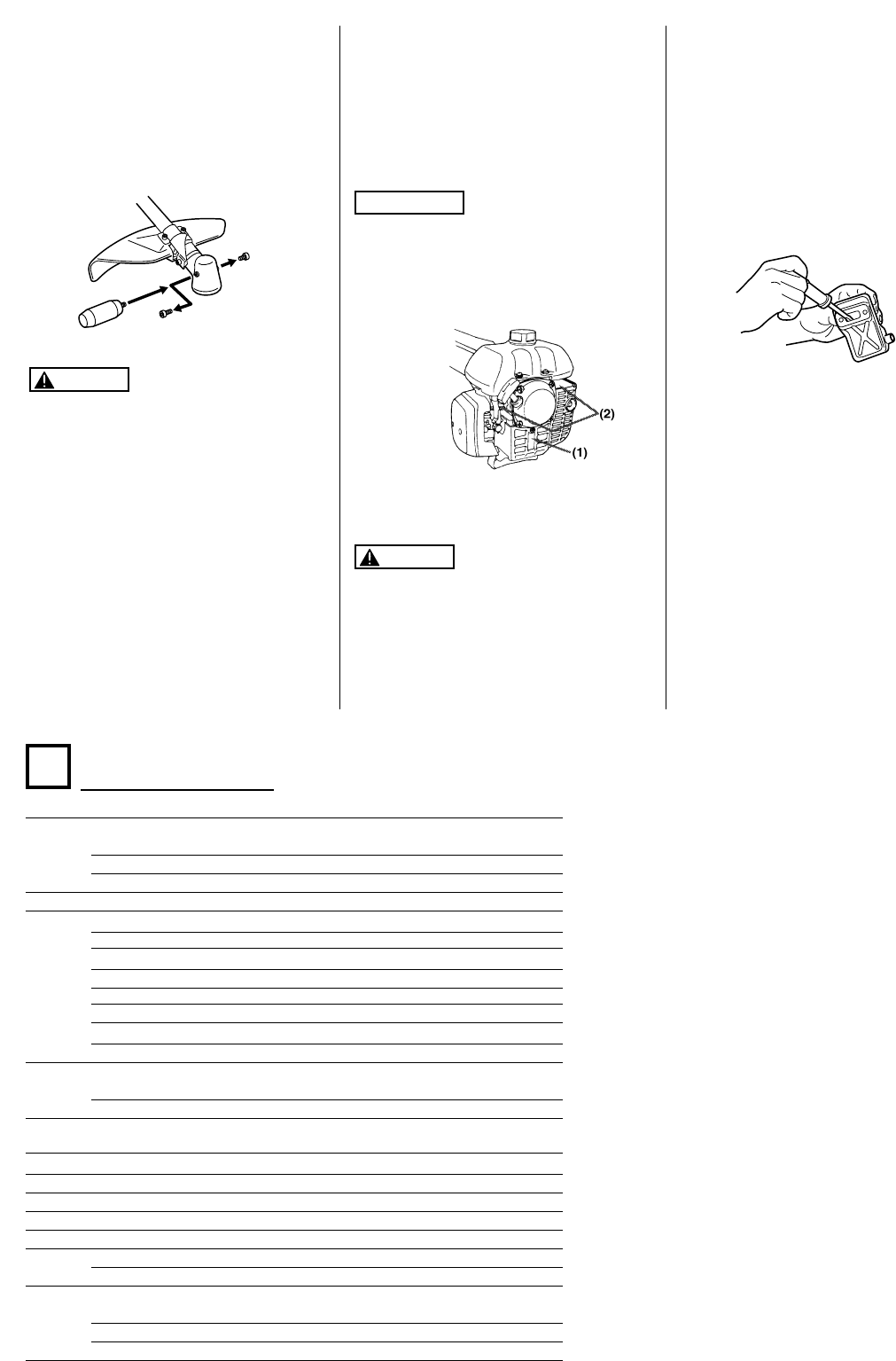

• Check the intake air cooling vent and the

area around the cylinder cooling fins after

every 25 hours of use for blockage, and

remove any waste which has attached

itself to the brushcutter. Note that it is

necessary to remove the engine cover

shown in in order to be able to view the

upper part of the cylinder.

If waste gets stuck and causes blockage

around the intake air cooling vent or between

the cylinder fins, it may cause the engine to

overheat, and that in turn may cause

mechanical failure on the part of the

brushcutter.

(1) Cylinder

(2) Intake air cooling vent

■ IMUFFLER

• Inspect periodically, the muffler for loose

fasteners, any damage or corrosion. If

any sign of exhaust leakage is found,

stop using the machine and have it

repaired immediately.

• Note that failing to do so may result in the

engine catching on fire.

WARNING

IMPORTANT