10

Motion Control Linkage Adjustment

This adjustment must be made with the rear

wheels rotating. Raise the rear of the machine

and block it up so the wheels are free to rotate.

CAUTION: Keep hands, feet and clothing

away from rotating tires.

Tilt seat forward and remove the seat rod so the

seat may rotate forward onto the frame.

Place a 2x4 board between the foot plate and

the center of the seat to engage the seat safety

switch.

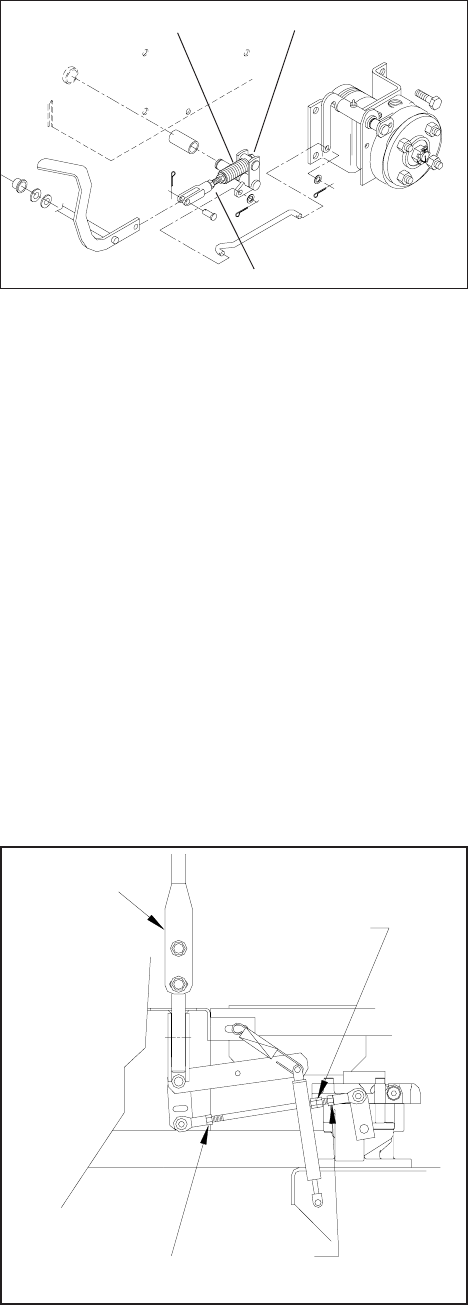

Loosen the nuts directly behind each ball joint

on both rods that connect the pump arm to the

motion control assemblies. FIG - 9

Start the engine. The park brake must be en-

gaged and the motion control levers in the

neutral slots to start the engine. Run the engine

approximately half throttle

Release park brake to allow the wheels to

rotate.

SETUP AND ADJUSTMENTS

Turn Here

To Adjust

Loosen Here

Loosen Here

(Lt. Hand Thds.)

Motion

Control

Lever

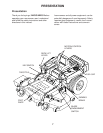

Park Brake Adjustment

When park brake is in the engaged position the

distance between the trunion and the bolt head

at the rear of the assembly should measure 1/8”

to 1/4” and the spring should measure 1.25”. To

adjust the gap between the trunion and the bolt

head loosen the nut against the yoke then turn

the bolt head the proper direction to achieve the

proper gap. To adjust the length of the spring

turn the nut against the spring the proper direc-

tion to lengthen or shorten the spring. This

adjustment is the same for both sides. FIG - 8

• If brake lever trys to catch as you engage the

brake the spring needs to be tightened. When

you change the spring length you also have to

maintain the 1/8” to 1/4” gap between the bolt

head and the trunion.

NOTE: Do not force the brake lever into the on

position if it is catching this will cause damage

to the brake assembly.

• If brake squeaks while the machine is in use.

The spring may be to tight or the gap between

the bolt head and the trunion may be to large.

Loosen here

1/4” Gap

Spring

FIG - 8

FIG - 9

Begin with either side and put the motion control

lever into the neutral position. Adjust the motion

control linkage by rotating the double nuts in the

proper direction until the wheel stops rotating.

FIG - 9 Move the motion control lever forward

then into the neutral position and place it into the

neutral slot. The wheel must be stopped com-

pletely at this point. Now do the same in reverse

and release the lever. The lever should return to

neutral on its own. If not see reverse spring

detent adjustment.