7

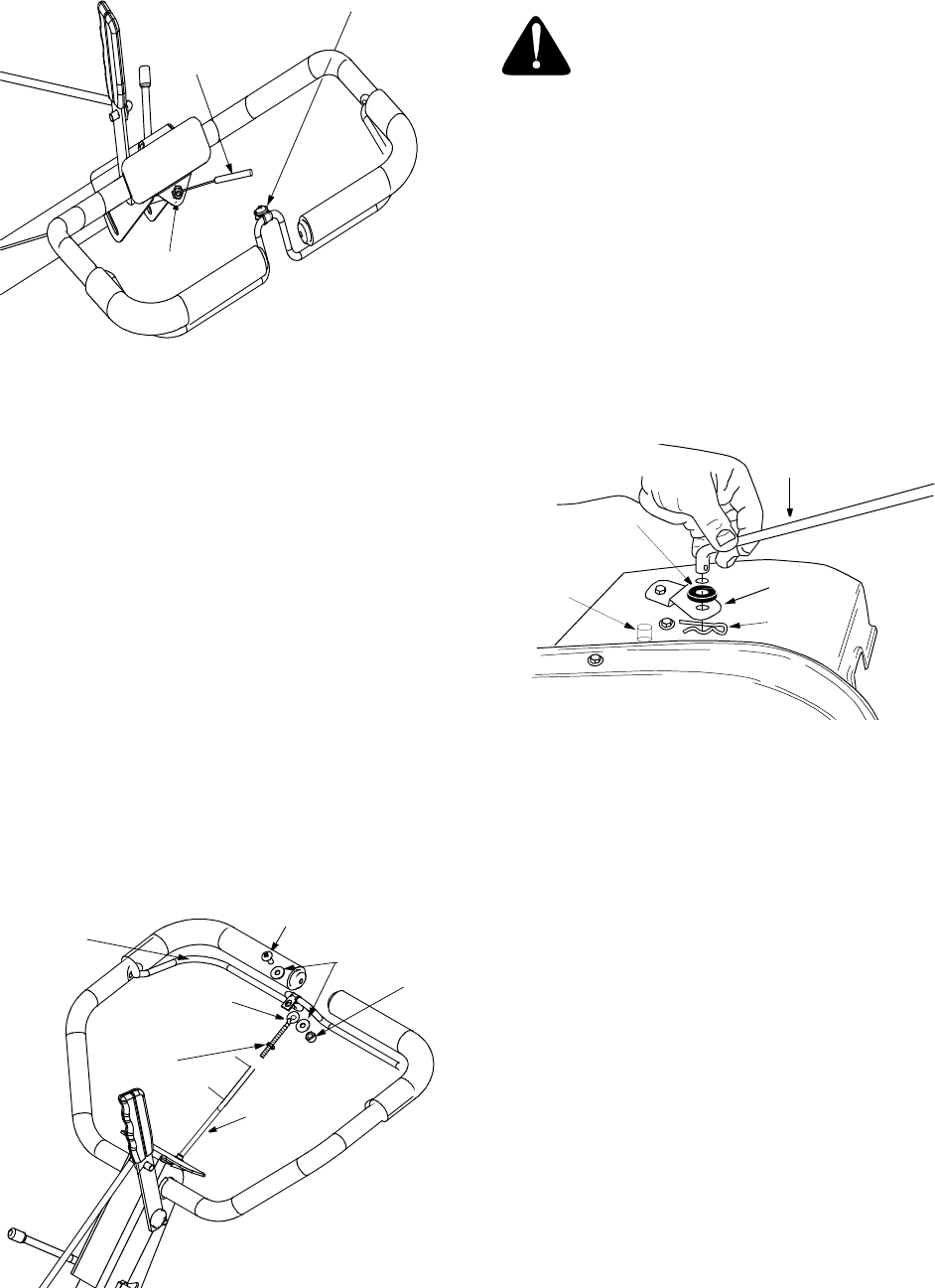

Figure 4

ATTACHING THE CLUTCH CABLE

Attach the clutch cable to the handle as follows (be

careful not to kink the cable).

• Remove threaded eyebolt and nut from the end of

the cable.

• Route the clutch cable to the right side of the

handle mounting brackets and underneath the

handle.

• Push the cable through the hole in the center of the

handle and snap in the plastic fitting. See Figure 4.

• Remove slot head screw, nut and two flat washers

from the clutch bail.

• Fasten the threaded eyebolt onto bail as shown in

Figure 5. The parts go together from top to bottom

as follows: Slot Head Screw, Flat Washer, Clip,

Eyebolt, Flat Washer and 1/4” Nut.

• Thread eyebolt and #10 nut, removed in step 1, into

the internally threaded tube at the end of the cable.

Thread engagement should be about 3/4”. Tighten

nut against tube at end of cable. See Figure 5.

Figure 5

NOTE: Do not overtighten clutch cable. Too much

tension may cause it to break.

WARNING: Be certain to check the

clutch cable adjustment as instructed on

this page before operating the tiller.

Secure clutch cable to handle using cable tie. Refer to

Figure 7. Cut off excess end of cable tie.

ATTACHING THE CONTROL ROD

• Remove hairpin clips from control rod, (rubber

washers to remain on control rod).

• Insert the shorter, (angled), end of the control rod

through the indicator bracket on the shift cover and

secure with hairpin clip that was removed in step 1.

See Figure 6.

• Insert the longer end of the control rod through the

hole in the gear selector handle and secure with

hairpin clip.See Figure 7.

.

Figure 6

CHECKING THE CLUTCH ADJUSTMENT

IMPORTANT:

Service the engine with oil and gasoline

before checking this adjustment. Refer to the separate

engine manual packed with your tiller for proper fuel

and engine oil recommendations.

Position the tiller so the front counterweight is against a

solid object, such as a wall. With the gear selection

lever in NEUTRAL, start the engine. Refer to the

separate engine manual.

Standing on the right side of the tiller, examine the belt

(inside the belt cover). It should not be turning.

NOTE: Do not put fingers under the belt cover.

If the belt turns without bail engaged, adjust by

unthreading the internally threaded tube at the end of

the cable a few turns clockwise (when standing in

operator’s position), and then retighten the nut against

the tube.

Plastic Fitting

Internally Threaded

Tube

Sl

ot

H

ea

d

S

crew,

Nut, Flat Washers

Slot Head Screw

Flat Washers

Threaded

Eyebolt

Internally

Threaded

Tube

Clutch

Bail

3

/

4

”

1/4”

Nut

#10

Nut

Indicator Bracket

Rubber

Washer

Control Rod

Hairpin

Clip

Idler

Pulley

Rod