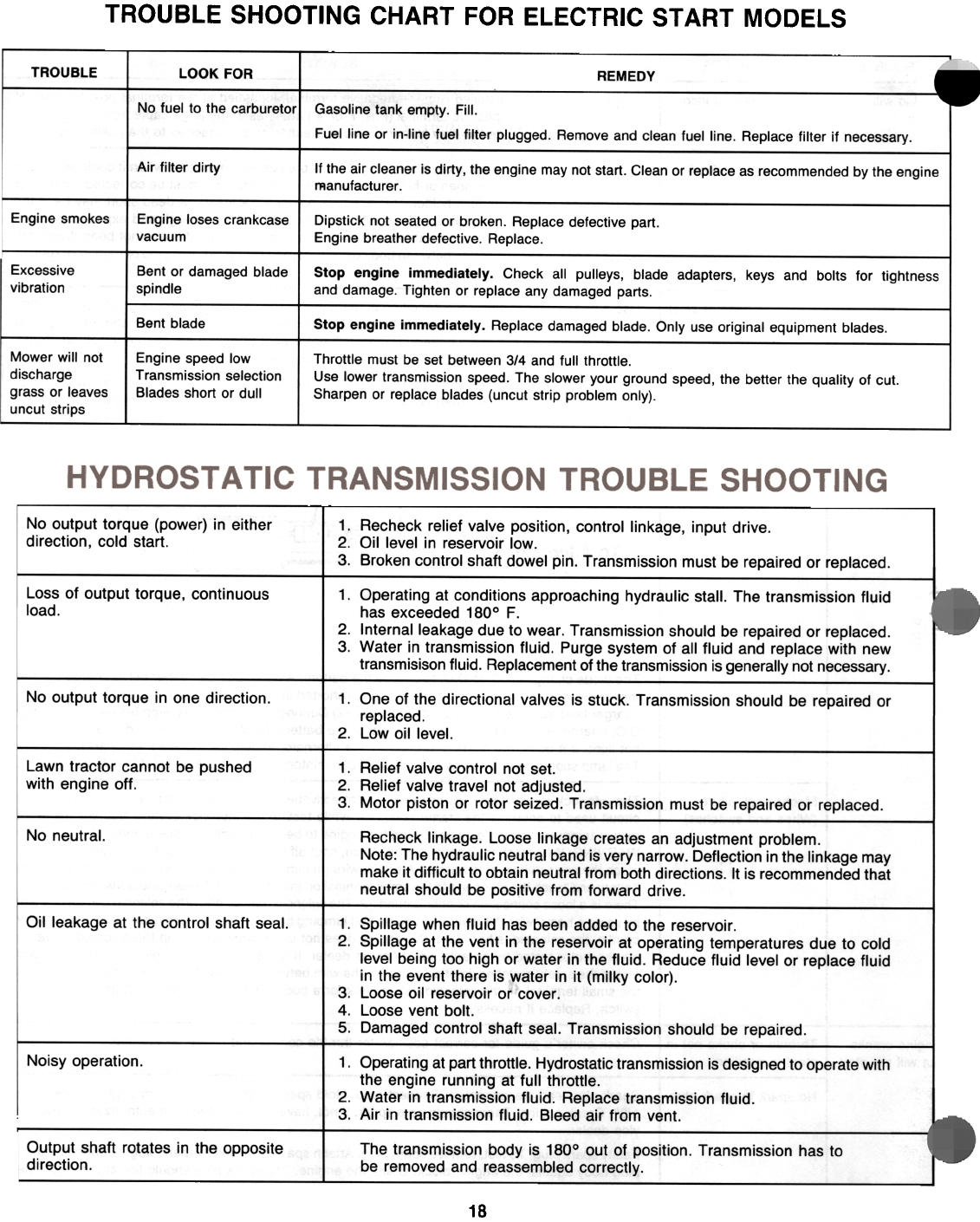

TROUBLE

SHOOTING CHART FOR ELECTRIC START MODELS

TROUBLE

LOOK FOR

REMEDY

No fuel to the carburetor!

Gasoline tank empty. Fill.

Fuel line or in-line fuel filter plugged. Remove and clean fuel line. Replace filter if necessary.

Air filter dirty

If the air cleaner is dirty, the engine may not start. Clean or replace as recommended by the engine

rRanufacturer.

Engine smokes

Engine loses crankcase

vacuum

Dipstick not seated or broken. Replace defective part.

Engine breather defective. Replace.

Excessive

vibration

Bent or damaged blade

spindle

Stop engine immediately. Check all pulleys, blade adapters, keys and bolts for tightness

and damage. Tighten or replace any damaged parts.

Bent blade

Stop engine immediately. Replace damaged blade. Only use original equipment blades.

Mower will not

discharge

grass or leaves

uncut strips

Engine speed low

Transmission selection

Blades short or dull

Throttle must be set between 3/4 and full throttle.

Use lower transmission speed. The slower your ground speed, the better the quality of cut.

Sharpen or replace blades (uncut strip problem only).

No output torque (power) in eitherdirection,

cold start.

1. Recheck relief valve position, control linkage, input drive.2.

Oil level in reservoir low.

3. Broken control shaft dowel pin. Transmission must be repaired or replaced.

Loss of output torque, continuous

load.

1. Operating at conditions approaching hydraulic stall. The transmission fluid

has exceeded 1800 F.

2. Internal leakage due to wear. Transmission should be repaired or replaced.

3. Water in transmission fluid. Purge system of all fluid and replace with new

transmisison fluid. Replacement of the transmission is generally not necessary.

No output torque in one direction.

1. One of the directional valves is stuck. Transmission should be repaired or

replaced.

2. Low oil level.

Lawn tractor cannot be pushed

with engine off.

1. Relief valve control not set.

2. Relief valve travel not adjusted.3.

Motor piston or rotor seized. Transmission must be repaired or replaced.

No neutral.

Recheck linkage. Loose linkage creates an adjustment problem.

Note: The hydraulic neutral band is very narrow. Deflection in the linkage may

make it difficult to obtain neutral from both directions. It is recommended that

neutral should be positive from forward drive.

Oil leakage at the control shaft seal.

1. Spillage when fluid has been added to the reservoir.

2. Spillage at the vent in the reservoir at operating temperatures due to cold

level being too high or water in the fluid. Reduce fluid level or replace fluid

in the event there is water in it (milky color).3.

Loose oil reservoir or cover.4.

Loose vent bolt.5.

Damaged control shaft seal. Transmission should be repaired.

Noisy operation.

1. Operating at part throttle. Hydrostatic transmission is designed to operate with

the engine running at full throttle.2.

Water in transmission fluid. Replace transmission fluid.

3. Air in transmission fluid. Bleed air from vent.

Output shaft rotates in the opposite

direction.

The transmission body is 1800 out of position. Transmission has to

be removed and reassembled correctly.

18