14

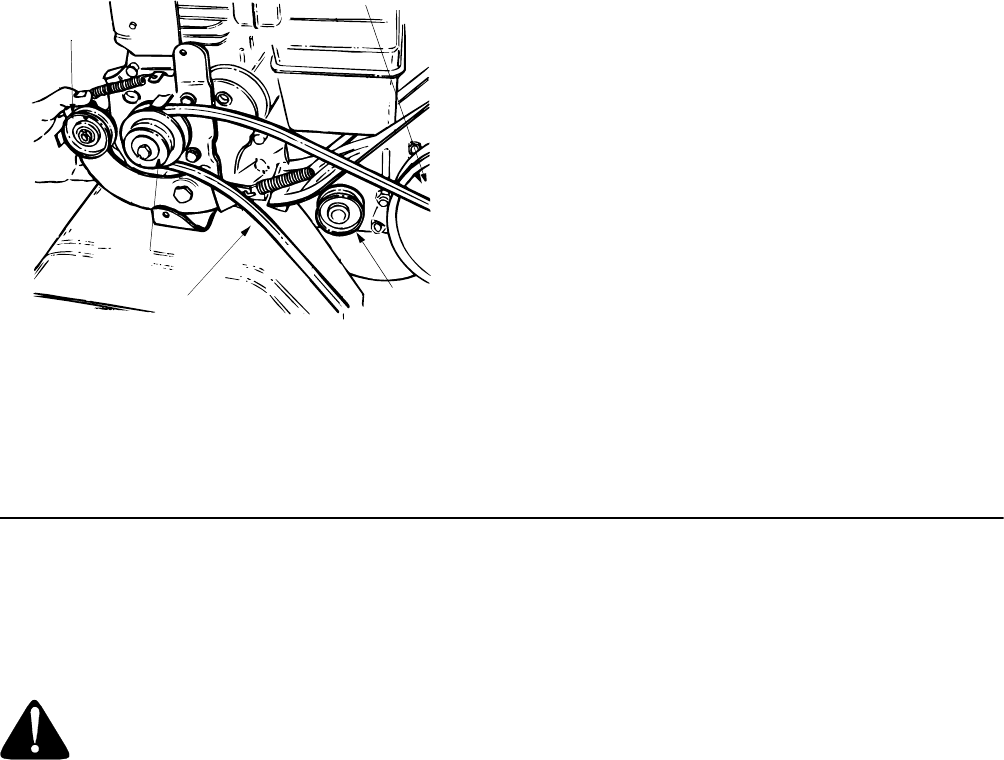

Figure 18

• Reassemble the new belt, following instructions in

reverse order. Make certain the reverse drive belt is

assembled with the wide side of the belt against the

transmission and engine pulleys.

Be certain to adjust the clutch control as instructed

in the final clutch adjustment section of assembly

instructions.

Forward Drive Belt See Figure 17

• Models 340 thru 345: Remove the belt cover by

following steps 1 thru 3 of the previous section.

Model 390: Remove the reverse drive belt as

instructed in the previous section.

• Remove the belt keeper from the idler pulley by

removing the idler pulley nut.

• Lift belt off the idler pulley and transmission pulley.

See Figure 18.

• Using a 9/16" wrench, remove bolt from engine

pulley.

• Push reverse idler pulley bracket forward, and

remove engine pulley and belt. See Figure 18.

• Reassemble the new belt, following instructions in

reverse order. Make certain the forward drive belt is

assembled with the wide side of the belt away from

the transmission and engine pulleys. Be certain to

adjust the clutch control as instructed in the final

clutch adjustment section of assembly instructions.

SECTION 7: OFF-SEASON STORAGE

If the tiller is to be inoperative for a period longer than

30 days, the following precautions are recommended.

• Working outdoors, drain all fuel from the fuel tank.

Run the engine until it stops from lack of fuel.

WARNING: Do not drain fuel while

smoking, or if near an open fire.

• Drain all the oil from the crankcase (this should be

done after the engine has been operated and is still

warm) and refill the crankcase with fresh oil.

• Protect the inside of the engine for storage as

instructed in the separate engine manual packed

with your tiller.

• Clean the engine and the entire tiller thoroughly.

• Wipe tines with oiled rag to prevent rust.

• We do not recommend the use of pressure

washers to clean your unit. It may cause damage to

electric components, spindles, pulleys, bearings or

the engine. The use of pressure washers will result

in shortened life and reduce serviceability.

NOTE: When storing any type of power equipment in

an unventilated or metal storage shed, care should be

taken to rustproof the equipment. Using a light oil or

silicone, coat the equipment, especially any springs,

bearings and cables.

• Store in a clean, dry area. Do not store next to

corrosive materials, such as fertilizer.

Reverse

Idler

Pulley

Engine

Pulley

Forward

Belt

Idler

Pulley

Nut

Transmission

Pulley