15

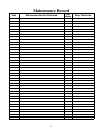

Spring platform Adjustment

The factory setting is both springs set at the most

forward position. The more rearward the spring

position, the stiffer the platform gets. Adjustment

will be to preference of feel. The two adjustment

springs should at all times, be positioned next to

each other not one forward or back more than the

other. To adjust, loosen each spring retaining bolt

from the top just enough to slide it, then tighten

with impact wrench. The nut may spin using hand

wrench. NOTE, do not loosen too much, if the nut

falls off, the foot platform will have to be removed

to reinstall. There is an extra hole for a third spring

for operators heavy enough to bottom out the duel

spring stock set up.

Hydro Oil Tank Check/Fill

Checking oil

• Ensure mower is on a level surface.

• Lift hinged pad and remove hex socket plug

from oil level port on the back of the tank.

• Hydro oil should be at the bottom of the threads.

Filling oil

• Lift hinged pad and remove hex socket plug.

• Using a funnel, fill tank through oil level port until

oil reaches bottom threads of the port.

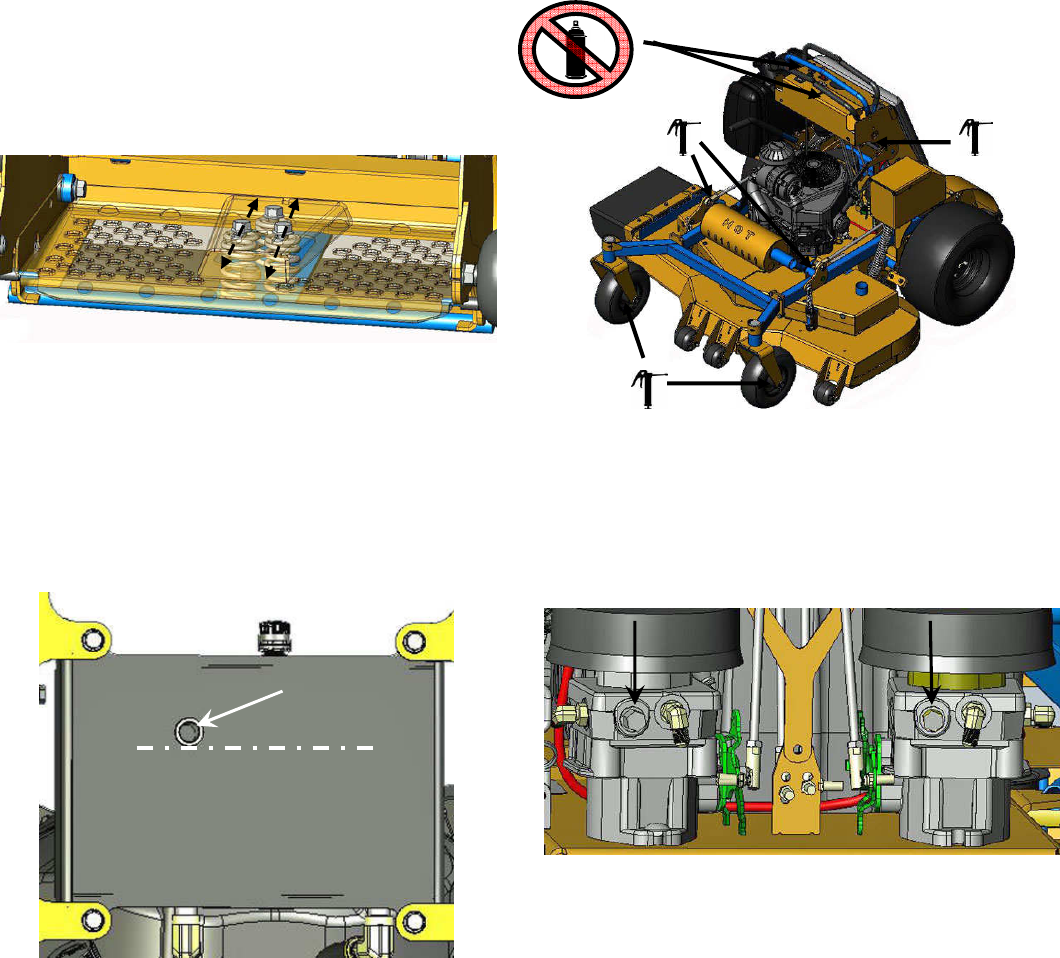

Lubrication

Grease with No. 2 general purpose lithium base or

molybdenum base grease.

• Set parking brake, stop the engine and

remove the key.

• Clean grease fittings with a rag.

• Connect grease gun to fitting and pump until

grease begins to ooze out from the

bearings.

• Wipe off excess grease.

• Do not use spray lube of any kind on choke

and/or throttle cables.

Service intervals:

First 8 hours

Every 25 hours

Also see Maintenance chart

How to Move the Mower if the Engine

Won’t Start

Rotate both of the hydro bypass valves on the side

of each hydraulic pump about ½ turn

counterclockwise. It is important not to over

tighten these. Damage may occur to the pump if

this valve is over tightened.

Bleeding Air from the Hydraulic System

Whenever servicing the hydraulic system, it is of

the utmost importance to keep any dirt or debris

from getting into the system. Clean off all parts

before disassembly and assembly. When any of

the hydraulic parts are disconnected or removed or

when the oil is changed, air must be bled from the

system. If air is entrained in the system, loss of

power, excessive heat, and damage to the

hydraulic pumps may occur. First, make sure the

oil level in the reservoir is correct. The oil should

be level with the bottom threads of the oil level

Fill Here