24 Assembly

MAN0813 (3/17/2010)

ASSEMBLY

Assembly of this rotary tiller is the responsibility of the

WOODS dealer. It should be delivered to the owner

completely assembled, lubricated and adjusted for nor-

mal conditions.

Do not allow bystanders in the area when oper-

ating, attaching, removing, assembling, or servic-

ing equipment.

Do not modify or alter or permit anyone else to

modify or alter the equipment or any of its compo-

nents in any way.

Always wear relatively tight and belted clothing

to avoid getting caught in moving parts. Wear

sturdy, rough-soled work shoes and protective

equipment for eyes, hair, hands, hearing, and head;

and respirator or filter mask where appropriate.

SET-UP INSTRUCTIONS

The rotary tiller is shipped partially assembled. Assem-

bly will be easier if components are aligned and loosely

assembled before tightening hardware. See “Bolt

Torque Chart” on page 37 for recommended torque

values.

Complete the Pre-Delivery and Delivery Check Lists on

page 26 when assembly is complete.

Select a suitable working area. Refer to illustrations,

accompanying text, parts lists, and exploded view

drawings.

For reference, front, back, left, and right directions are

determined by sitting in the tractor operator’s seat.

DISASSEMBLE SHIPPING UNIT

It is advisable to have a mechanical lifting device to

facilitate uncrating.

Be careful of nails in boards when uncrating.

1. Remove all parts that are wired and strapped to

tiller and/or crate.

2. Remove top, sides, and ends of crate.

3. Remove front rubber shield from the bottom of the

crate (reverse rotation models only).

4. Remove lag screws from L-shaped shipping brack-

ets. Remove L-brackets from the tiller. Be sure to

save the mounting hardware for later use.

5. Remove tiller assembly from crate base.

6. Remove loose nails from boards and dispose of

crate according to local codes.

ASSEMBLY PROCEDURES

Required tools: 9/16", 3/4”, 1-1/8" combination

wrenches, sockets, torque wrench, and jack stands.

1. Lower skid shoes to lowest position and stand tiller

upright.

2. Use jack stands to support the front frame tube

with tiller sitting on the ground.

3. Install parking stand (33) and spring assembly to

tiller frame using 1/2NC x 3-1/4 cap screw (67) and

flange nut (62).

4. Unbolt lower hitch clevises (34), rotate 90 degrees,

and re-install in operating position, 26" from center

to center. Figure 23, page 25.

5. Install driveline (8) to gearbox input shaft.

6. Attach right mast plate (27) and driveline holder

(80) to gearbox frame using 3/8NC x 1-1/4 serrated

flange screws (83) and flange whiz nuts (60).

Attach driveline holder on outside of mast plate

using the front two holes. Use 3/8NC x 1 serrated

flange screws (55) and flange whiz nuts (60) to

attach mast plates (27 & 28) to gearbox stand in

remaining holes Figure 23, page 25.

7. Install CAT 1 quick hitch sleeve (70) using 3/4NC x

3-1/2 cap screw (68) and lock nut (69). Install in

the lower hole in the top of the mast plates.

8. Attach driveline tether chain to the tiller hitch frame.

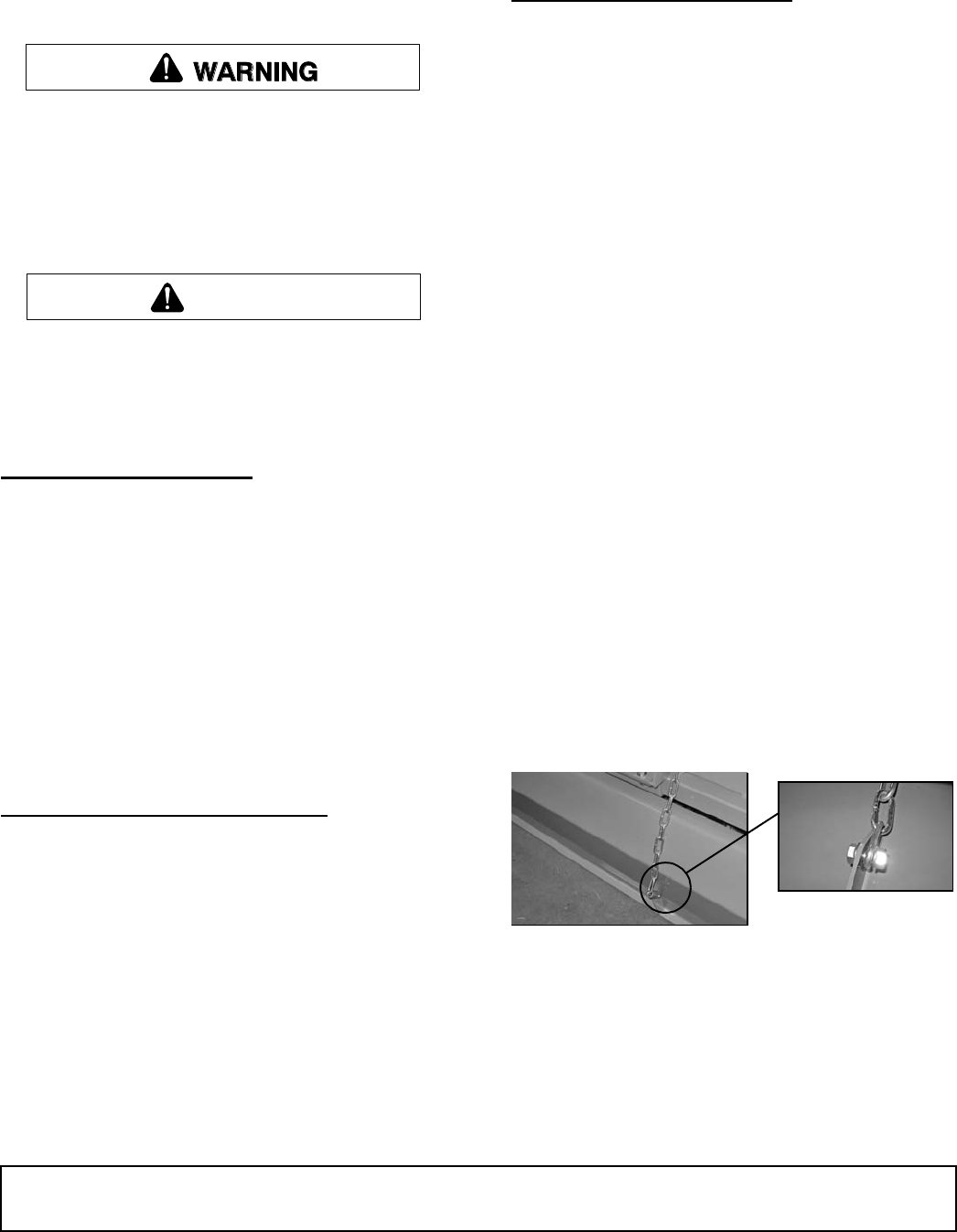

9. Attach tailgate chain to lug on tailgate using pack-

ing slip instructions in hardware bag. Thread the

chain through the keyhole slot on the top safety

shield support. Secure the chain by sliding the

desired link into the narrow portion of the keyhole

slot.

Figure 22. Attaching Tailgate Chain

10. Attach front rubber deflector and clamp bar using

5/16NC x 1 carriage bolts (53) and flange whiz nuts

(54). (Reverse models only)

11. Fill gearbox with SAE 80W or 90W gear lube until it

runs out the center side level plug.

NOTE: Chain case has .8 quarts of 00 grease

installed at factory. This grease is very viscous and

will stick to chain at 70°F.

CAUTION

(Rev. 8/3/2011)