12 Operation

MAN0813 (3/17/2010)

8. File and clean the cut ends of both drive halves.

Ensure the drive halves slide smoothly together.

Do not run the tractor if proper driveline engagement

cannot be obtained through these methods.

Connect the driveline to tractor PTO shaft, making sure

the spring-activated locking collar slides freely and

locks driveline to PTO shaft.

NOTICE

■ If attaching with quick hitch, the distance

between the tractor PTO and gearbox input shaft

will increase. Please follow the steps as you would

for a 3-point hitch to insure proper engagement.

WORKING DEPTH ADJUSTMENT

Keep all persons away from operator control

area while performing adjustments, service, or

maintenance.

1. Raise the tiller off the ground.

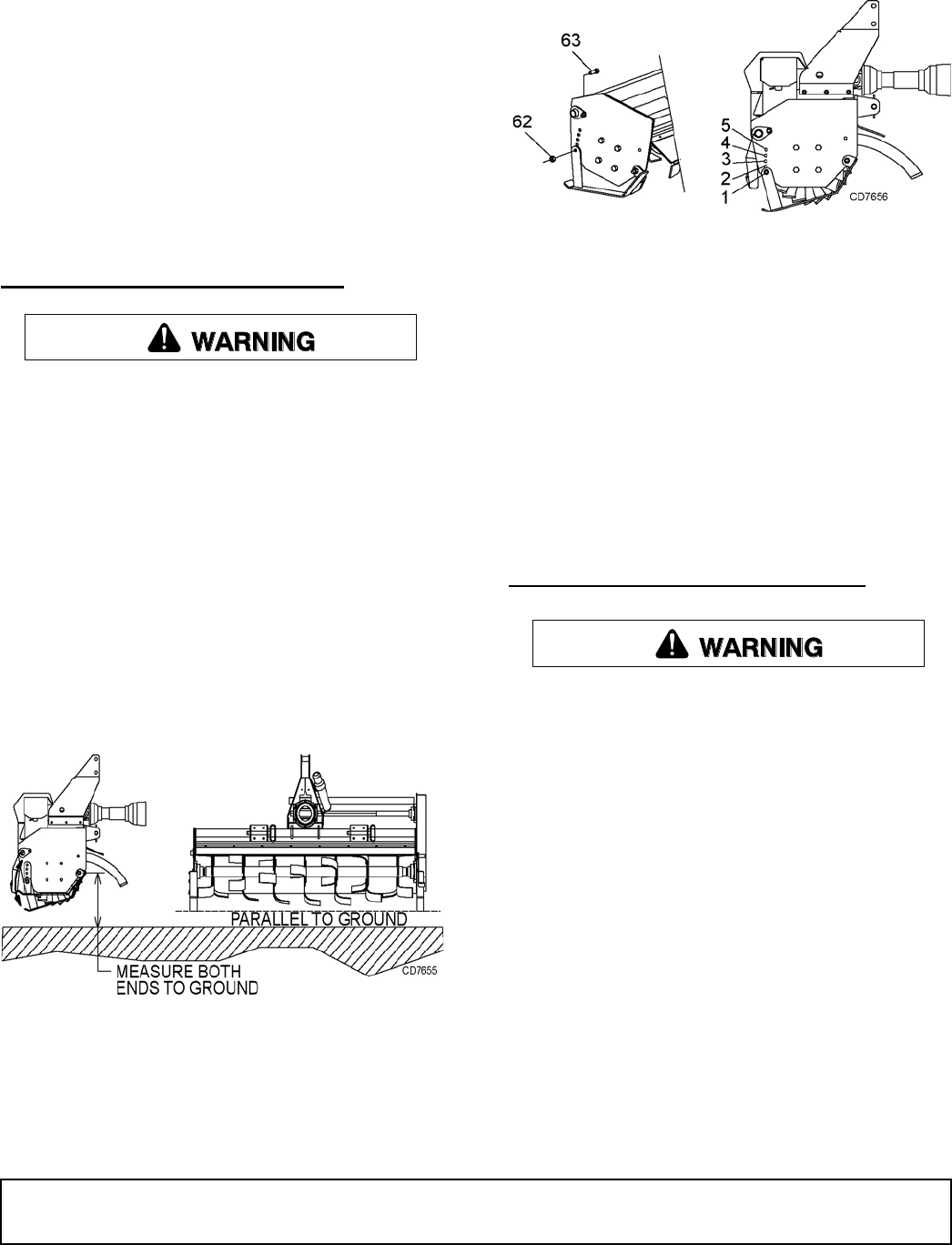

2. Level tiller side to side. Check by measuring from

the forward skid shoe pivot to the ground on each

side. (Figure 5)

3. Adjust, using tractor 3-point arm leveling device.

NOTE: Keep the front of the tiller parallel to the

ground.

4. Place two jack-stands under the tiller rotor shaft.

Figure 5. Leveling the Tiller

5. Loosen the 1/2” cap screws that act as the front

pivots to the skid shoes. Remove the 1/2” cap

screws (63) that hold the rear of the skid shoes to

the tiller frame.

6. Adjust the skid shoe to the desired tilling depth

(Figure 6). Reinstall the cap screws in the rear of

the skid shoe and tighten all cap screws.

Figure 6. Tiller Depth Adjustment

NOTE: Tillage depth is dependent on ground hard-

ness, tractor speed, skid shoe setting, and tractor

hitch adjustment. Multiple passes may be neces-

sary to achieve tillage depth.

TILLER SIDE SHIFT ADJUSTMENT

■ Make sure parking stand is secured in the

down position and skid shoes are in hole one

before performing the following service work.

1. Disconnect tiller from tractor.

2. Measure rear tractor tire width (outside to outside).

3. Calculate side shift needed. Divide rear tractor tire

width by two and tiller width by two. Subtract tiller

width from tractor width and add five inches. Check

maximum tiller side shift capability on the specifica-

tion page of this manual, page 4. The calculated

side shift must be less than the maximum side

shift. (Example: Tractor rear tire width = 70”, TC60

Tiller = 60”. 70/2 = 35”, 60/2 = 30”. 35-30 = 5” + 5”

extra = 10” side shift.

4. Loosen nuts on U-bolts on lower clevis hitch (4), U-

bolts on front gearbox stand (2), and bolts at the

back of the gearbox stand (2). See Figures 7 and

8.

Hole

First Pass

Depth

10”

21”

32”

43”

54”

62 1/2NC Flange Nut

63 1/2NC Cap Screw

(Rev. 6/7/2011)