Assembly 39

MAN0707 (5/30/2008)

Install Wing Wheel Yoke Adjustment Link

Use a suitable lifting device of sufficient capac-

ity. Use adequate personnel to handle heavy com-

ponents.

1. With a lifting device raise right wing and lock in the

up position using the wing lock-up bar. Leave lifting

device attached for added support.

2. Attach adjustable link (8) to right side of center

wheel yoke arm and secure with cap screw (28)

and lock nut (33).

3. Attach opposite end of adjustable link (8) to wing

wheel yoke arm and secure with cap screw (28)

and lock nut (33).

4. Remove lock-up bar and carefully lower wing using

lifting device.

5. Repeat process for left wing. (BW126R only has

right wing installed; BW126L only has left wing

installed.)

Figure 34. Left Wing Wheel Yoke

Adjustment Link Installed

Install Wing Driveline

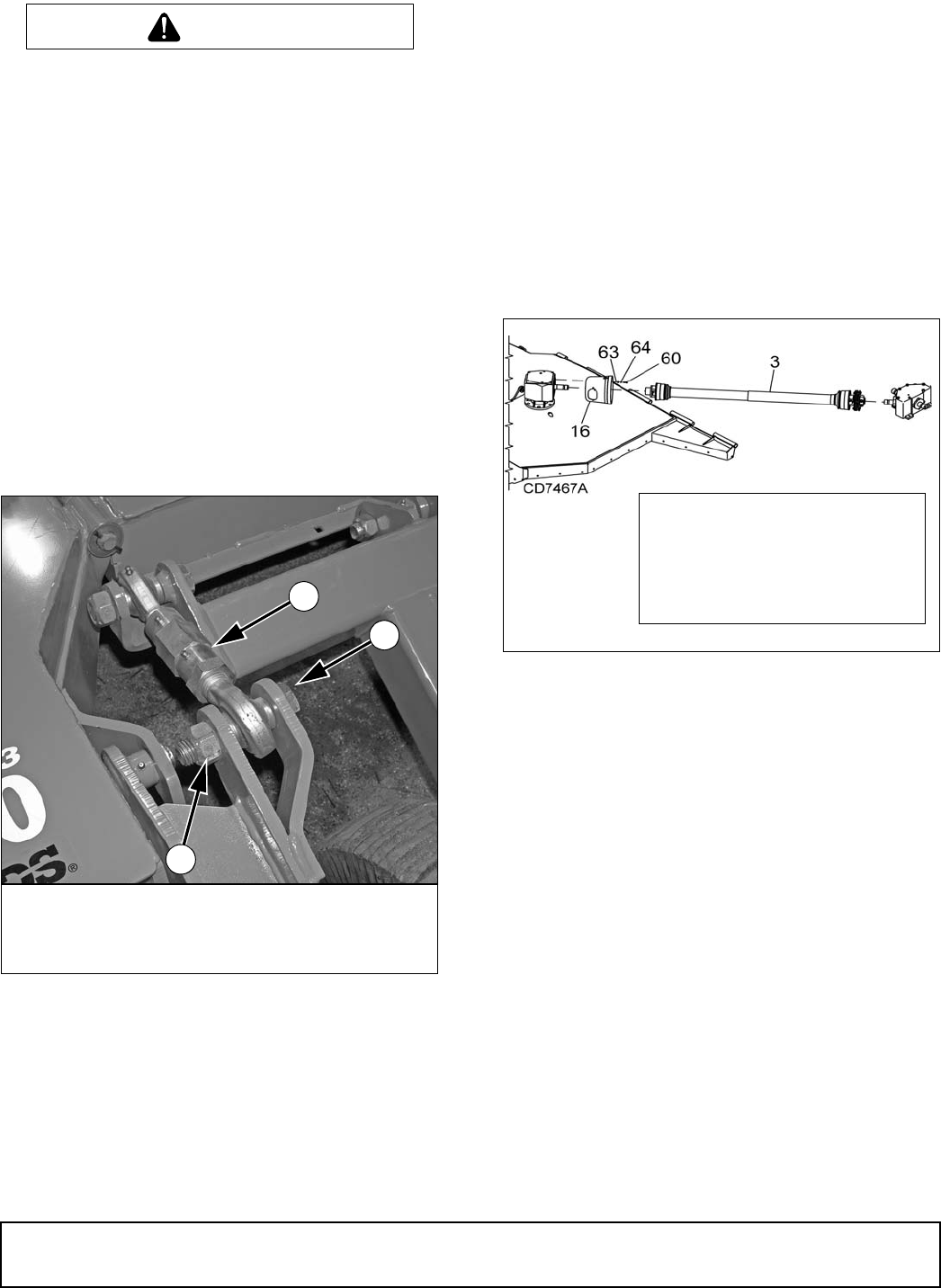

1. Attach clutch shield (16) to wing gearbox using four

cap screws (60), lock washers (64), and flat

washers (63).

2. Slide non clutch end of driveline (3) over wing

gearbox shaft and align holes with groove.

3. Secure driveline to shaft using cap screws and lock

nuts supplied with driveline.

4. Slide clutch end of driveline over splitter gearbox

and secure using cap screws and lock nuts

supplied with driveline.

5. Repeat process for left driveline. (BW126R only

has right wing installed; BW126L only has left wing

installed.)

Figure 35. Right Driveline Installation

Install Hose Kit

1. Remove plug from rod end of each wing cylinder.

2. With the wings in the down position and cylinder

extended, remove and reinstall the plugs from the

base of the wing cylinders. This will trap air behind

the piston and help when lowering the wings.

3. Install reducer bushing and restricter elbow into

cylinders. Position elbow on center cylinder to point

forward; on wing cylinders point elbows to the

center.

NOTE: Make sure a breather fitting is installed in

the rod end port of the wheel yoke cylinder.

4. Attach hose to each elbow.

CAUTION

8

28

33

DP2

8. Adjustable link

28. 1 NC x 4-1/2 HHCS GR5

33. 1 NC Lock nut

3. Driveline, complete

16. Clutch shield

60. M8 x 1.25P x 20 mm HHCS

63. 5/16" Flat washer

64. 5/16" Lock washer

(Rev. 10/19/2009)