unigreen 9

4.1.1 WORK STATIONS

The use of this machine does not envisage an operator standing constantly

near the same, the operator normally sits in the cab of the tractor.

During calibration and maintenance operations the operator will be working near

the machine at ground level (for all the calibration and maintenance operations

refer to the relevant chapters).

In case of operations that request the entry to parts of the machines located

at 1,5 mt. height ,it is advised to use a ladder at rule; the ladder shall be

positioned steady on a flat ground not yielding and with the machine at a

standstill and braked.

In some special models with controls above 1.5 metres there is a platform to

make these operations easier.

This platform must only be used with the machine stopped.

NOTE: Put the ladder back into the correct operating position after use,

securing it with the hook; make sure not to pinch or crush your hands during

these operations.

4.1.2HAND WASHING TANKS

The sprayers are supplied with an auxiliary hand-washing tank with clean water

and a hand tap.

This tank must always be supplied with water and the inside must be clean so

you can wash any parts of the body that come into contact with the chemical

product used.

Never drink the liquid inside.

4.2 PRELIMINARY CHECKS

When you receive the machine, check that it is complete and no parts are

missing.

If there are any damaged parts, inform your local reseller or UNIGREEN

directly in good time.

When the machine is delivered, make sure you ask:

a) that the machine is delivered with all of its parts fitted and that the fitting

meets the requisites in table N° 12 pag. 33-34. (This procedure is necessary

because for reasons of space during transportation the machine is often

delivered partially dismantled).

b) that it is tested in your presence in particular checking:

= that the suction filter and the inside of the tank are clean and free of work

residues.

= that the connections are made correctly following the basic layout (FIG. N°

11).

= that the hose clips and all the unions and connections are tightened

properly.

= that any herbicide boom is mounted in the centre.

= that all of the protective covers are fitted solidly to the machine, in particular

the protective cover of the power-takeoff of the pump.

= Check the proper tyres inflation (pressure are indicated on tyres)

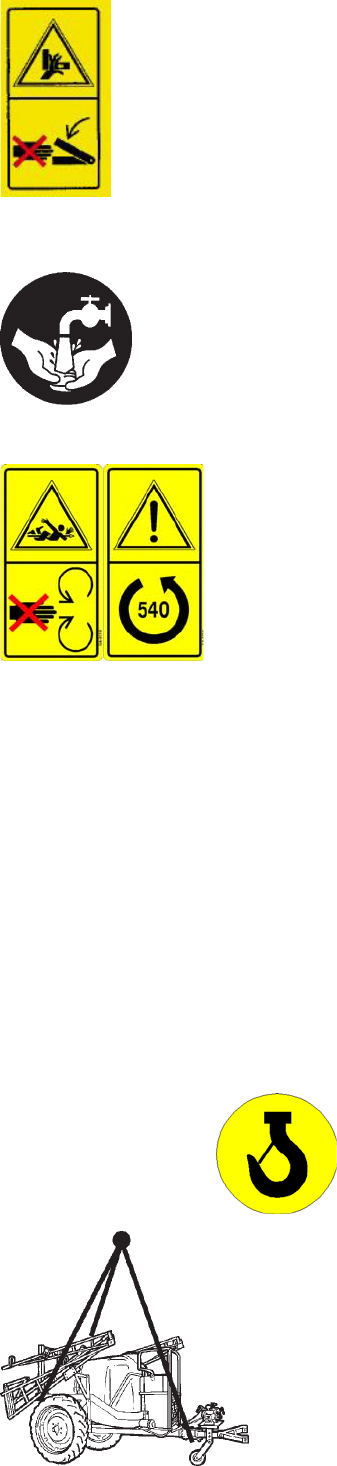

4.3 TRANSPORTING AND MOVING THE MACHINE

Every time you have to lift the machine, before starting the operation, always

make sure the lifting gear and the relevant tools and equipment (cables,

hooks, etc..) are suitable for lifting the load and check the stability of the

same.

It is forbidden to unhook and move the machine with the tank full.

The dry weight of the machine at the maximum level of fitting and with all the

accessories allowed is stamped on the nameplate (Fig. 2); use slings and

lifting gear with a adequate load-bearing capacity.

Don’t stand the sprayer on soft ground or steep slopes.

Never lift or move the sprayers by hand if there is liquid in the tank. The

machine will weigh more and the movement of the liquid can change the centre

of gravity causing uncontrolled movements.

We recommend using slings as shown in the figure, the lifting points to use on

the machine are indicated with the relevant symbol.

Don’t lift the machine with the forks of a forklift truck because the machine can

tip over due to the overhanging weight of the booms.

Don’t pass or stand under the machine when it is being lifted.

This symbol identifies the

clean water tank on the

machine used to wash

your hands

This symbol

identifies the

coupling points of

the machine