12 unigreen

4.4.5 HYDRAULIC CONNECTION TO THE DISTRIBUTORS

The machines that need a hydraulic connection to drive the herbicide booms

are equipped with 1/2", “Push-Pull”, quick-fit male couplings. You can connect

the pipes by simply pushing them in, making sure you:

- proceed only with the engine turned off;

- lower any tools connected to the elevator of the tractor;

- carefully clean the two parts that will be coupled

Warning: the hydraulic cylinders used are the “Double Effect” type.

Consult the use and maintenance manual of the tractor.

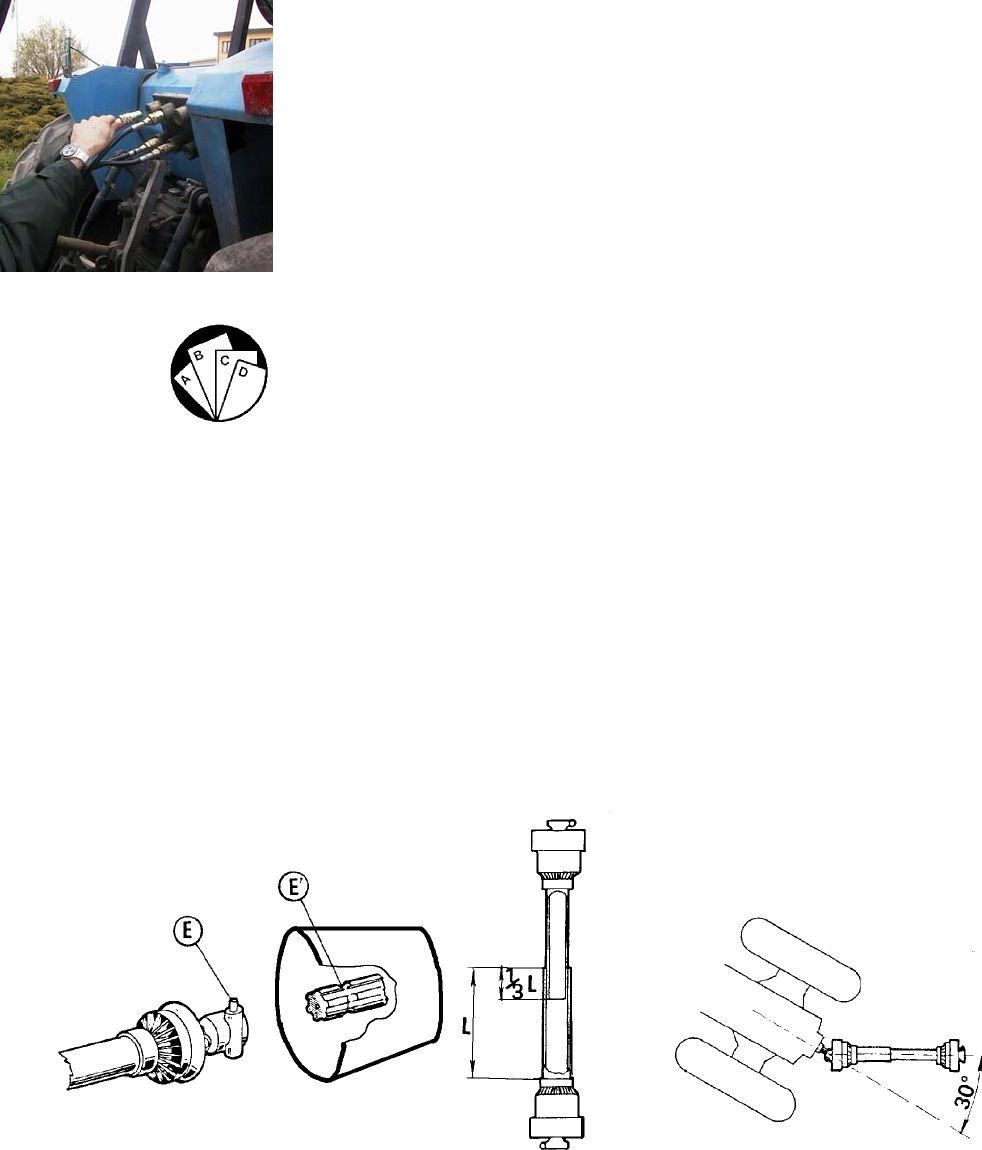

4.5 CARDAN SHAFT

In some models this is supplied on request.

The cardan shaft must bear the CE mark.

It must always have its own instructions that must be followed scrupulously

and it should come with a cover bearing the mark, integrated in every part.

You should have previously checked the length to avoid:

= if it is too long, DANGEROUS THRUST ON THE PUMP SHAFT

= if too short, the POSSIBILITY OF DANGEROUS BREAKAGES

THE MINIMUM OVERLAP OF THE TWO TELESCOPIC TUBES MUST

NEVER BE LESS THAN 1/3 OF THE LENGTH OF THE TUBES.

The power that can be transmitted by the cardan shaft must be at least equal

to that required to run the sprayer. Consider that the power necessary to run a

sprayer without the fan is practically the same as that of the pump, the power

rating can be found in the pump instructions handbook. Generally 20 bar

pumps need 20 hp; 50 bar pumps need 30 hp. These power ratings can be

found in tables N° 12 pages 33-34.

NEVER USE THE CARDAN TRANSMISSION IF THE FOLLOWING

PROTECTIVE COVERS ARE MISSING:

a)TRACTOR POWER-TAKEOFF PROTECTIVE COVER

b) CARDAN SHAFT PROTECTIVE COVER

c) FIXED PROTECTIVE COVER ON THE PUMP SHAFT

d) Hook any safety chains to solid anchor points

e)Check that the button or ringnut “E” (FIG. 4) is correctly engaged and

blocked both on the pump side and on the tractor side.

f) Don’t exceed an inclination of 30°-35° in any direction for any reason

g) With the machine stopped, periodically grease the spiders and the pipes,

keeping the connecting zone particularly clean.

h) Avoid letting the end of the cardan shaft come into contact with the ground

with the machine stopped; use the relevant support on some versions for this,

if your machine has no support, hook the external safety chain to a part of the

frame of the machine (ex. control unit support).

FIG. 4