MAINTENANCE AND REPAIR INSTRUCTIONS

Reinstalling the Air Filter/Muffler Cover

1. Place the air filter/muffler cover over the back of the carburetor

and muffler. Align the screw holes.

2. Insert the four (4) screws into the holes in the air filter/muffler

cover (Fig. 21) and tighten. Do not over tighten.

SPARK ARRESTOR MAINTENANCE

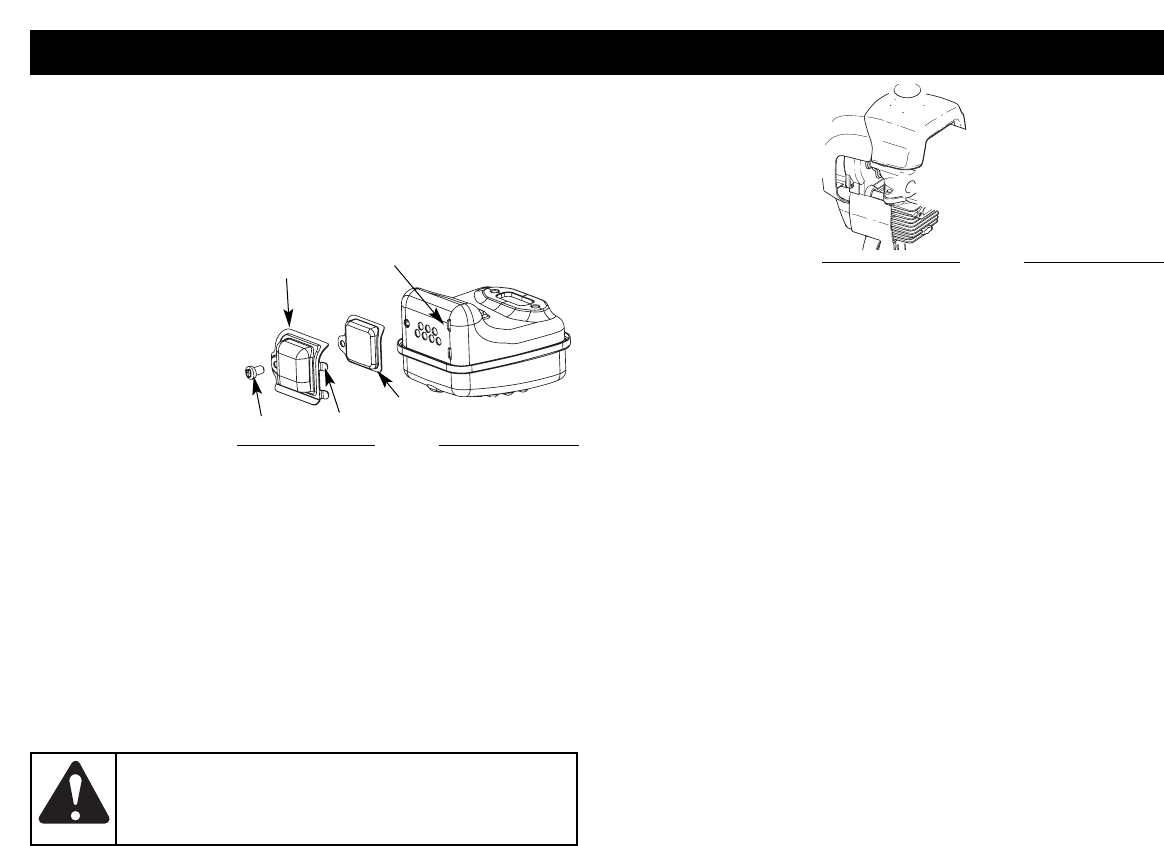

1. Remove air filter/muffler cover. Refer to Removing the Air

Filter/Muffler Cover.

2. Locate the muffler,

but do not remove it.

Find the screw on

the bottom of the

muffler (Fig. 26).

Remove the screw

using either a torx

#20 or flat blade

screwdriver.

3. Carefully pry up the

left side spark

arrestor hood. Two tabs act as hinges on the right side of the

hood. Flip open the spark arrestor hood like a door and then

pull its tabs out of the muffler slots.

4. Using a small flat blade screwdriver, carefully pry the spark

arrestor screen out from the inside of the spark arrestor hood.

5. C

lean the spark arrestor screen with a wire brush. Replace it if it is

damaged, or if you are unable to clean it thoroughly.

6.

Reinstall the spark arrestor screen snugly back into the spark arrestor

hood.

7. Reinstall the two hood tabs into the two muffler slots and flip

the spark arrestor hood closed.

8. Replace the screw you removed in Step 2 and tighten it securely.

9. Reinstall the air filter/muffler cover.

CARBURETOR ADJUSTMENT

The idle speed of the engine is adjustable through the air filter/muffler

cover (Fig. 27).

NOTE: Careless adjustments can seriously damage your unit. An

authorized service dealer should make carburetor

adjustments.

CHECK FUEL MIXTURE

Old and/or improperly mixed fuel is usually the reason for improper unit

performance. Drain and refill the tank with fresh, properly-mixed fuel

prior to making any adjustments. Refer to Oil and Fuel Information.

CLEAN AIR FILTER

The condition of the air filter is important to the operation of the unit. A

dirty air filter will restrict air flow and change the air/fuel mixture. This is

often mistaken for an out of adjustment carburetor. Check the condition

of the air filter before adjusting the idle speed screw. Refer to Air Filter

Maintenance.

ADJUST IDLE SPEED SCREW

If, after checking the fuel mixture and cleaning the air filter, the engine

still will not idle, adjust the idle speed screw as follows:

1. Start the engine and let it run at a high idle for a minute to warm

up. Refer to Starting/Stopping Instructions.

2.

Release the throttle trigger and let the engine idle. If the engine

stops, insert a small phillips screwdriver into the hole in the air

filter/muffler cover (Fig. 27). Turn the idle speed screw in, clockwise,

1/8 of a turn at a time (as needed) until the engine idles smoothly.

3. If the engine appears to be idling too fast, turn the idle speed

screw counterclockwise 1/8 of a turn at a time (as needed), to

reduce idle speed.

Checking the fuel

mixture, cleaning the air

filter, and adjusting the

idle speed should solve

most engine problems. If

not and all of the

following are true:

•

the engine will not idle

•the engine hesitates

or stalls on

acceleration

•there is a loss of engine power

Have the carburetor adjusted by an authorized service dealer.

REPLACING THE SPARK PLUG

Use a Champion RDJ7Y spark plug, or equivalent. The correct air gap

is 0.025 inch (0.635 mm). Remove the plug after every 25 hours of

operation and check its condition.

1. Stop the engine and allow it to cool. Grasp the plug wire firmly

and pull it from the spark plug.

2. Clean around the spark plug. Remove the spark plug from the

cylinder head by turning a 5/8-inch socket counterclockwise.

3. Replace a cracked, fouled or dirty spark plug. Set the air gap at

0.025 in. (0.635 mm)

using a feeler gauge

(Fig. 28).

4. I

nstall a correctly-

gapped spark plug in

the cylinder head.

Tighten by turning the

5/8-inch socket

clockwise until snug.

If using a torque wrench torque to:

110-120 in.•lb. (12.3-13.5 N•m)

Do not over tighten.

CLEANING

Use a small brush to clean off the outside of the unit. Do not use strong

detergents. Household cleaners that contain aromatic oils such as pine and

lemon, and solvents such as kerosene, can damage plastic housing or

handle. Wipe off any moisture with a soft cloth.

STORAGE

•Never store a fueled unit where fumes may reach an open flame

or spark.

•Allow the engine to cool before storing.

•Store the unit locked up to prevent unauthorized use or damage.

•Store the unit in a dry, well-ventilated area.

•Store the unit out of the reach of children.

LONG TERM STORAGE

If you plan on storing the unit for an extended time, use the following

storage procedure:

1. Drain all fuel from the fuel tank into a container with the same

2-cycle fuel mixture. Do not use fuel that has been stored for

more than 60 days. Dispose of the old fuel/oil mix in

accordance to Federal, State and Local regulations.

WARNING:

If the spark arrestor hood and spark

arrestor screen are not tightened securely, they could fall

off causing damage to the unit and possible serious

personal injury.

Fig. 26

Tabs

Screw

Spark Arrestor

Hood

Spark Arrestor

Screen

Slots

Fig. 27