19

CHECKING AND ADJUSTING

FORWARD DRIVE BELT TENSION

It is important to maintain correct tension

on the forward drive belt. A loose belt will

cause the tines and wheels to slow down —

or stop completely — even though the en-

gine is running at full speed. A too tight

belt can result in unintentional tine move-

ment when the clutch bail is in the Neutral

(released) position.

• Check belt tension after the first two

hours of break-in operation and after every

10 operating hours.

• At the end of each tilling season, check

the belt for cracks, cuts or frayed edges

and replace it as soon as possible.

To Check Forward Belt Tension:

1. Stop engine, wait for all parts to stop

moving and disconnect spark plug wire.

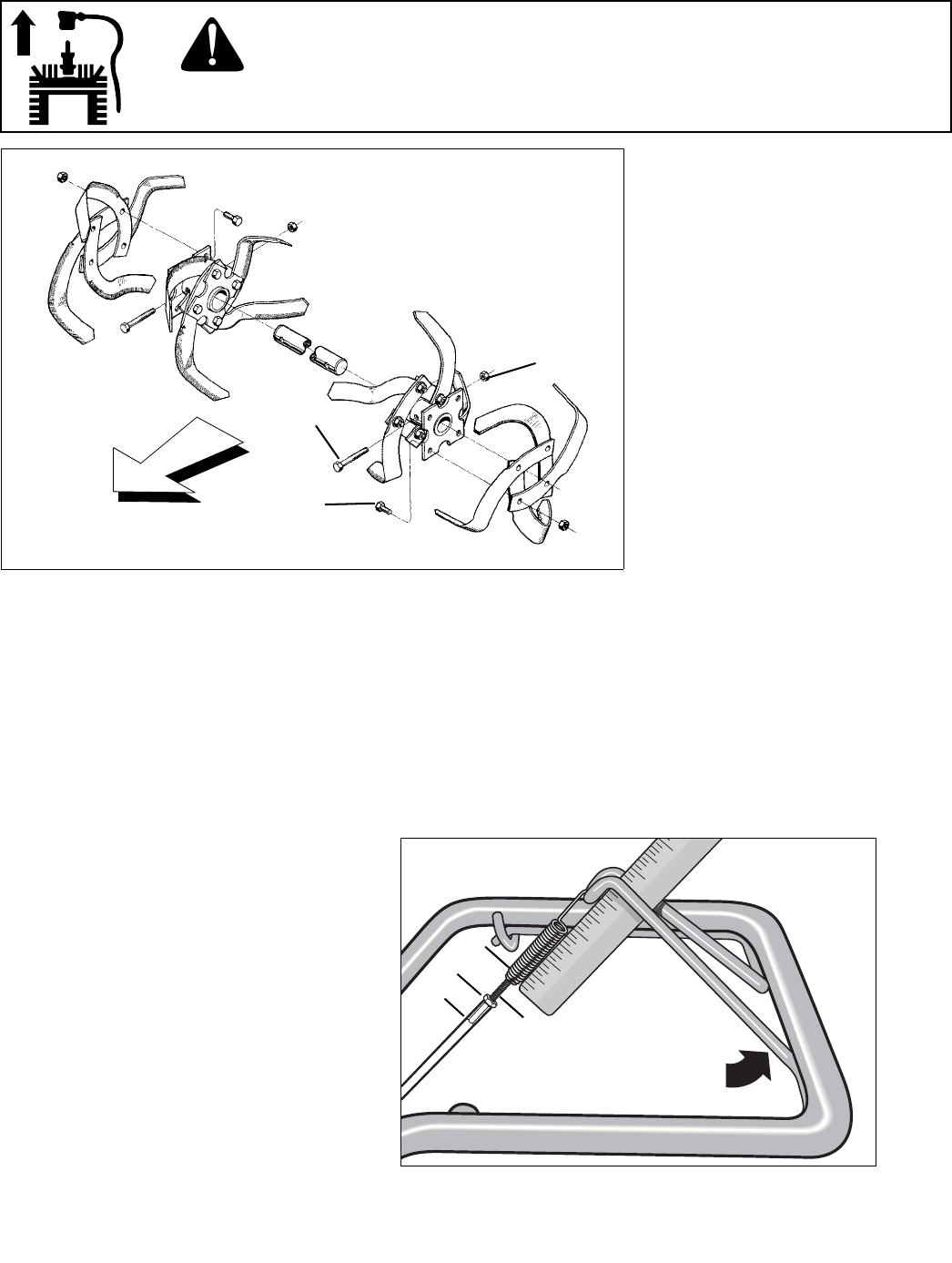

2. With the Forward Clutch Bail in an open

(released) position, measure and note the

overall length of the cable spring (A, Figure

5-4) by measuring from the outermost coil

to the outermost coil.

3. Squeeze the Forward Clutch Bail against

the handlebar (see Figure 5-4) and re-

measure the length of the coils. The belt

tension is correct if this second measure-

ment is between 1/6" -to- 3/16" longer than

the first measurement.

4. If the spring is too short (less than

1/16"), the tension is too loose. If the

spring is too long (more than 3/16"), the

tension is too tight.

5. To adjust the length of the spring:

a. Release the Forward Clutch Bail.

b. Unthread the hex nut (C, Figure 5-4)

halfway up the adjustment screw (D).

c. Unhook the top of the spring from the

Forward Clutch Bail.

d. Use pliers to prevent the adjuster (B)

from turning and turn the slotted screw lo-

cated inside the spring clockwise (viewed

from operator’s position) to increase ten-

sion on the spring. Turn the screw counter-

clockwise to decrease tension. Once

adjusted, reattach the spring to the For-

ward Clutch Bail.

e. Repeat Steps 2 and 3 to re-measure the

length of the spring. When the second mea-

surement is between 1/16" -to- 3/16" longer

than the first measurement, retighten the hex

nut (C) against the top of the adjuster (B).

Replacement Belt Information

If the drive belt needs to be replaced, see

your local authorized dealer or refer to the

Parts List for ordering information. Use

only a factory-authorized belt as an “over-

the-counter” belt may not perform satis-

factorily. The procedure requires average

mechanical ability and commonly available

tools.

Figure 5-3: Install tines so that cutting edge of tines enter soil first when tiller moves forward.

C

D

B

A

FORWARD

Figure 5-4: To check forward belt tension, take two measurements of the

overall length of the coils in the spring — first with the clutch bail open,

then with the clutch bail closed against the handlebar.

WARNING: Before inspecting, cleaning or servicing the machine, shut off engine, wait for all

moving parts to come to a complete stop, disconnect spark plug wire and move wire away from

spark plug. Failure to follow these instructions can result in serious personal injury or property

damage.

1

2

3

4

5

Hold bail against handlebar while

taking second measurement of spring

C

B

A

D