11

5

WARNING

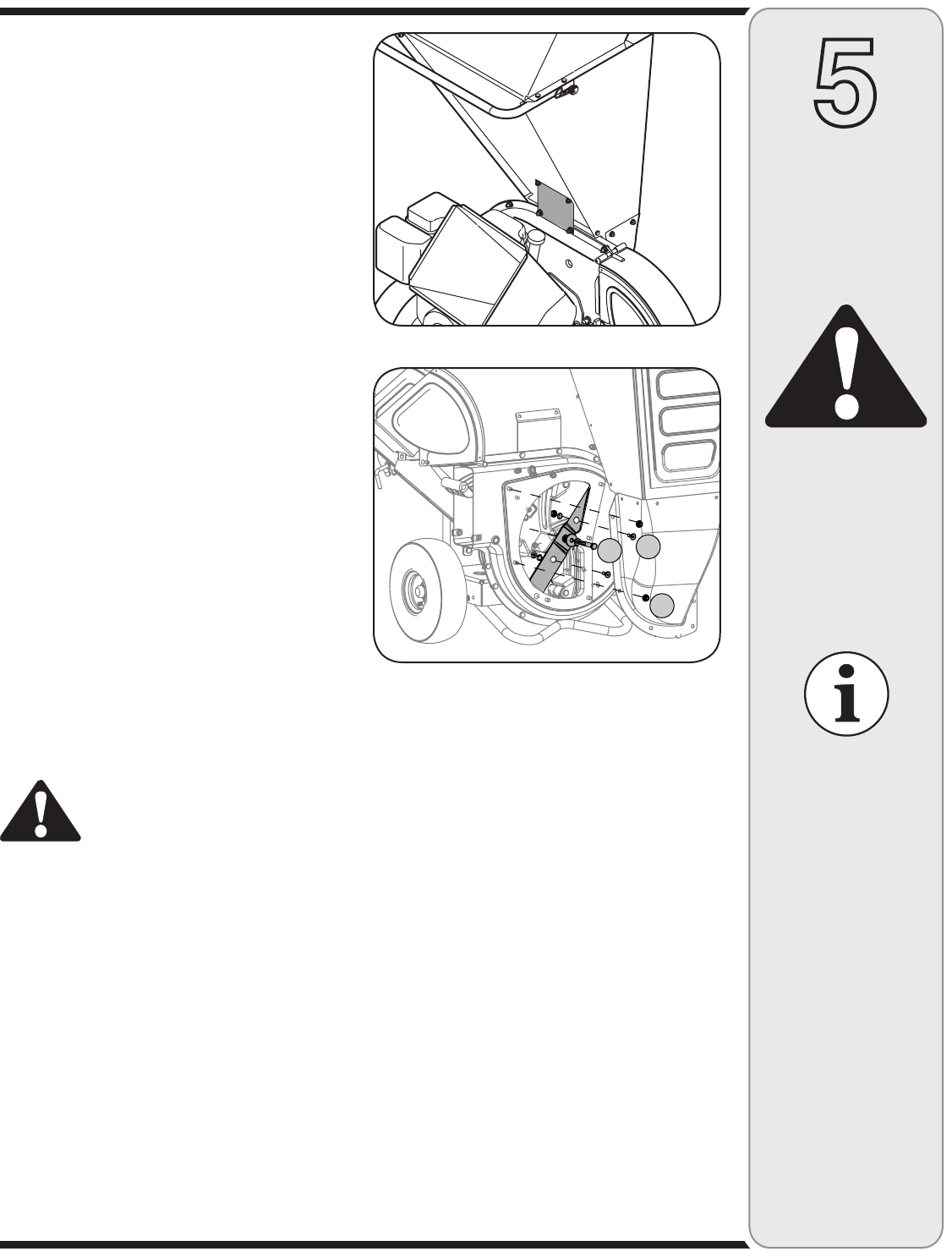

Figure 10

Figure 11

The shredder blade is

sharp. Wear leather

work gloves to

protect your hands.

Maintaining

Your Chipper

Shredder

IMPORTANT

Make certain chipper

blades are reassem-

bled with the sharp

edge outward (toward

the chipper chute).

Torque hardware to

between 20 ft.-lbs and

25 ft.-lbs.

2. Pivot the shredder screen upward as instructed under

the heading Cleaning the Reduction Chamber.

3. a. Remove the chipper chute support brace from the

frame by removing the two hex bolts and saddle

washers which secure it. See Figure 9.

b. Remove the chipper chute by removing three hex

nuts and washers which secure it to the impeller

housing. See Figure 9.

• Rotate the impeller by hand until one of the two

chipper blades is visible through the impeller

housing opening.

c. Remove the blade by removing the internal hex

screws, lock washers and hex nuts which secure it

to the impeller. Retain the hardware.

NOTE: Use a 3/16” hex key (Allen) wrench on the outside

of the blade and a 1/2” box (or socket) wrench on the

inside of the impeller. Hold the Allen wrench stationary

and rotate the box (or socket) wrench to loosen the nut.

4. Install a replacement blade (Part No. 742-0544) with

the hardware removed earlier or sharpen.

IMPORTANT: When sharpening the blade, protect hands

by using gloves. Follow the original angle of grind and

make sure to remove an equal amount from each blade.

5. To replace the other blade, rotate the impeller to

expose the second blade and repeat the steps above.

NOTE: Make certain blades are reassembled with the

sharp edge outward (toward the chipper chute). Torque

hardware to between 20 ft.-lbs and 25 ft.-lbs.

Sharpening Or Replacing The

Shredder Blade

WARNING: The shredder blade is sharp.

Wear leather work gloves to protect

your hands.

1. Stop engine,disconnect spark plug, and make certain

that all moving parts have come to a complete stop.

2. Remove the two flange nuts (and hex bolts) which

secure the hopper support bracket to the impeller

housing. Retain the hardware. See Figure 10.

3. Pivot the shredder screen upward as instructed under

the heading Cleaning the Reduction Chamber.

4. a. Remove six flange nuts which secure hopper inlet

guide to impeller housing. See Figure 11.

• Carefully separate the hopper assembly from the

impeller housing and set it aside.

• Insert a piece of wood into the chute deflector

opening to stabilize the impeller and prevent it from

rotating when removing the shredder blade.

b. Remove the two internal hex screws, hex lock nuts,

and lock washers which secure the shredder blade

to the impeller. See Figure 11.

NOTE: Use a 3/16” hex key (Allen) wrench on the

outside of the shredder blade and a 1/2” box (or socket)

wrench on the inside of the shredder blade. Hold the

Allen wrench stationary and rotate the box (or socket)

wrench to loosen the nut.

c. Remove the hex bolt, lock washer, and flat washer

to completely free shredder blade. See Figure 11.

IMPORTANT: If sharpening the blade for reuse, follow

the original angle of grind as a guide. Make certain each

cutting edge receives an equal amount of grinding to

prevent an unbalanced blade. Remove metal from the

heavy side until it is balanced evenly.

IMPORTANT: When reassembling the blade, tighten

center bolt to between 45 ft.-lbs and 60 ft.-lbs and the

two out bolts to between 20 ft.-lbs and 25 ft.-lbs.

Storing Your Chipper Shredder

1. Clean the equipment thoroughly.

2. Wipe equipment with an oiled rag to prevent rust.

3. Refer to engine manual for correct engine storage

instructions

4. Store unit in a clean, dry area. Do not store next to

corrosive materials such as fertilizer.

IMPORTANT

When reassembling the

shredder blade, tighten

center bolt to between

45 ft.-lbs and 60 ft.-lbs

and the two out bolts to

between 20 ft.-lbs and

25 ft.-lbs.

A

C

B