25

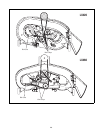

• Check the gap using a feeler gauge and adjust, if

necessary, by carefully bending the ground

electrode. See Figure 16. Set the spark plug gap to

.76 mm (0.030 in.).

Figure 16

• Reinstall the spark plug into the cylinder head.

Torque the spark plug to 38.0/43.4 N·m (28/32 ft.

lb.).

• Place the spark plug wire boot over the spark plug

and press until you feel it “click” in place.

Fuel Filter

WARNING: Do not replace the fuel filter

when engine is hot.

The engine is equipped with an inline fuel filter located

on the right side of the engine.

Visually inspect the filter periodically for a build-up of

residue inside the filter body, and for a dirty element

which can be indicated by discoloration. Replace the

fuel filter when dirty.

Cleaning the Engine

Any fuel or oil spilled on the machine should be wiped

off promptly.

Do NOT allow debris to accumulate around the cooling

fins of the engine or on any other part of the machine,

especially the belts and pulleys.

Lubrication

WARNING: Before lubricating, repairing, or

inspecting, always disengage PTO, set

parking brake, stop engine and remove key to

prevent unintended starting.

Engine

Refer to Engine on page 22 for instruction regarding all

engine-related lubrication.

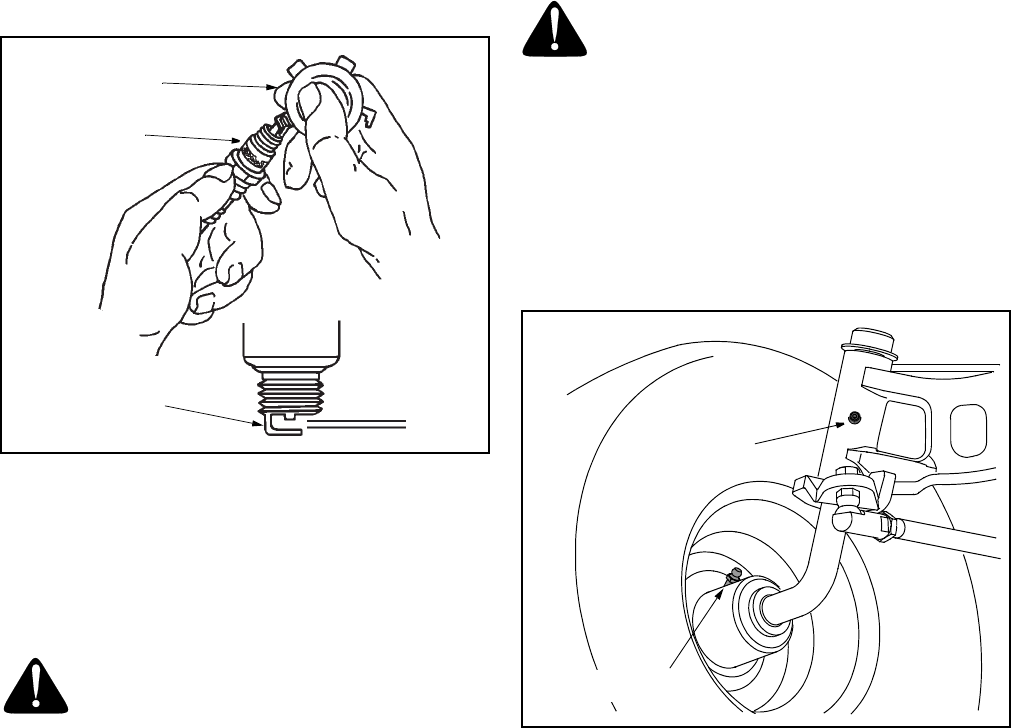

Front Wheels

Each of the front wheel axles and rims is equipped with

a grease fitting. See . Lubricate with 251H EP grease or

an equivalent No. 2 multi-purpose lithium grease after

every 25 hours of tractor operation.

Figure 17

Pivot Points & Linkage

Lubricate all the pivot points on the drive system,

parking brake and lift linkage at least once a season

with light oil.

Feeler Gauge

Ground Electrode

Spark Plug

Gap

Axle Grease Fitting

Rim Grease Fitting