Installation Procedure ___________________________________________________

To assure maximum performance from your 800S series sprinklers, read these instructions

completely prior to installation or service.

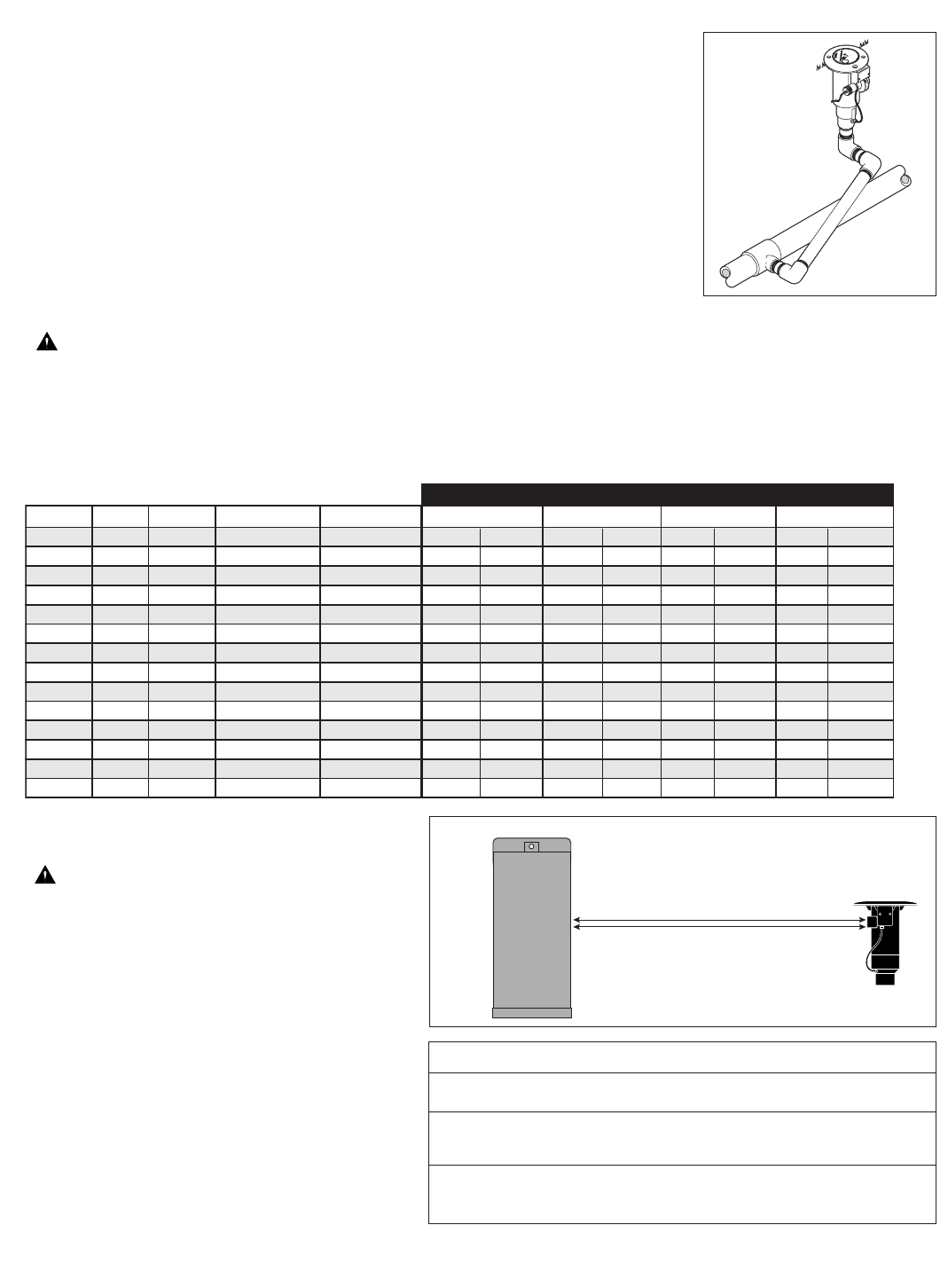

Constructing Swing Joints

1. Construct or provide triple swing joints for each sprinkler as shown in Figure 1. Use PVC or

ABS pipe nipple for the sprinkler connection.

Note: On sites where the possibility of heavy equipment rolling over a sprinkler exists, the

swing joint will flex preventing damage to the lateral or main lines. On a new installation in

raw ground where the sprinklers are to be initially installed above the finished grade and

lowered when new turf is established, the swing joint allows sprinkler repositioning without

changing risers. This is a common and practical procedure which eliminates the problem of

dirt being accidentally introduced into the lateral lines when a riser is changed.

2. Flush lines thoroughly prior to installing sprinkler.

3. Apply PTFE tape on riser threads (not required on ACME threads). Install sprinkler to riser and tighten.

CAUTION: Use only PTFE tape on riser threads. Use of pipe dope or other types of sealing compounds can cause

deterioration of sprinkler body threads.

Connecting Control Wires (Electric Models Only)

1. Route control wires to sprinklers. Provide extra wire at sprinkler to allow for height adjustment. One common wire and station

wire is required for each sprinkler. See Wire Sizing Chart, Table 1 for proper application.

Note: Wire length data provided in Table 1 is the sum of the station and common wire legs. See example in Figure 2.

2. Attach control wires to solenoid leads using an

approved waterproof splicing method.

CAUTION: All wire splices and field

connections must be waterproofed to prevent

short circuit to ground and subsequent controller

damage.

Connecting Hydraulic Control Tubing

1. Route control tubing from the controller to the

sprinkler location(s).

Note: Leave an 18" (45.7 cm) service loop of tubing

at each sprinkler to facilitate movement of sprinkler

and service operations. Refer to Table 2 for tubing

run length and sprinkler elevation information.

2. Flush tubing thoroughly to remove all air and debris.

3. Remove the tube retainer and poly cap from the

tubing adapter at the base of the sprinkler.

4. Slide the tube retainer over the end of the control

tubing and attach tubing to adapter.

5. Slide tube retainer over adapter area to secure tubing.

3

Table 2: Hydraulic Control Systems

Maximum Distance

Type of System* From Controller Elevation Restrictions

Normally Open (01) Valve elevation should not exceed

with 3/16" Control Tubing 500' 25' ABOVE controller elevation or

70' BELOW controller elevation.

Normally Open (01) Valve elevation should not exceed

with 1/4" Control Tubing 1000' 25' ABOVE controller elevation or

70' BELOW controller elevation

Voltage AWG mm

2

Voltage Drop

Circular Mils 1 Sprinkler

Total Wire Length Between Controller and Sprinkler

2 Sprinklers3 Sprinklers 4 Sprinklers

23

14/14

2.5/2.5

2.5/4.0

2.5/5.5

4.0/4.0

4.0/5.5

4.0/7.0

5.5/5.5

2.5/2.5

2.5/4.0

2.5/5.5

4.0/4.0

4.0/5.5

4.0/5.5

4 4100 3285' 1001 m

1298 m

1770 m

1595 m

2067 m

2812 m

2540 m

1251 m

1622 m

2213 m

1993 m

2584 m

3515 m

3175 m

500 m

649 m

885 m

797 m

1033 m

1406 m

1270 m

626 m

811 m

1106 m

996 m

1292 m

1757 m

158

7 m

334 m

432 m

590 m

531 m

689 m

937 m

846 m

417 m

541 m

738 m

664 m

861 m

1172 m

1058 m

250 m

324 m

443 m

399 m

517 m

703 m

635 m

313 m

406 m

553 m

498 m

646 m

879 m

790 m

1642' 1095' 821'

23

14/12

45315

4259' 2129' 1419' 1064'

23

14/10

4 7250

5809' 2904' 1936' 1452'

23

12/12

46530

5232' 2616' 1744' 1308'

23

12/10

4 8465

6783' 3391' 2261' 1695'

23

12/8

4 11515

9227' 4613' 3075'

2306'

23

10/10

4 10400

8333' 4166' 2778'

2083'

24 14/14 5 4100 4106' 2053' 1369' 1026'

24 14/12 5 5315

5323'

2662' 1774'

1331'

24 14/10 5 7250 7261' 3631'

2420'

1815'

24

12/12

56530 6540' 3270' 2180' 1635'

24

12/10

5 8465 8478' 4239' 2826'

2119'

24

12/8

5 11515 11533'

5766'

3844'

2883'

24

10/10 10/10

5 10400 10416' 5208' 3472' 2604'

Table 1: Wire Sizing Chart

*

- All hydraulic connections on Toro valves are

1

⁄4" insert type.

- Control line pressure must be equal to or greater than mainline pressure.

- Control line pressure range is 40 to 150 PSI.

A U

T O

O

N

O

F F

Figure 1

Figure 2

Station Wire = 1095' (334m)

Common Wire = 1095' (334m)

Total Wire Length = 2190' (668m)