78

2015 Toro Commercial Equipment Guide 15-003-T Rev. 2/15

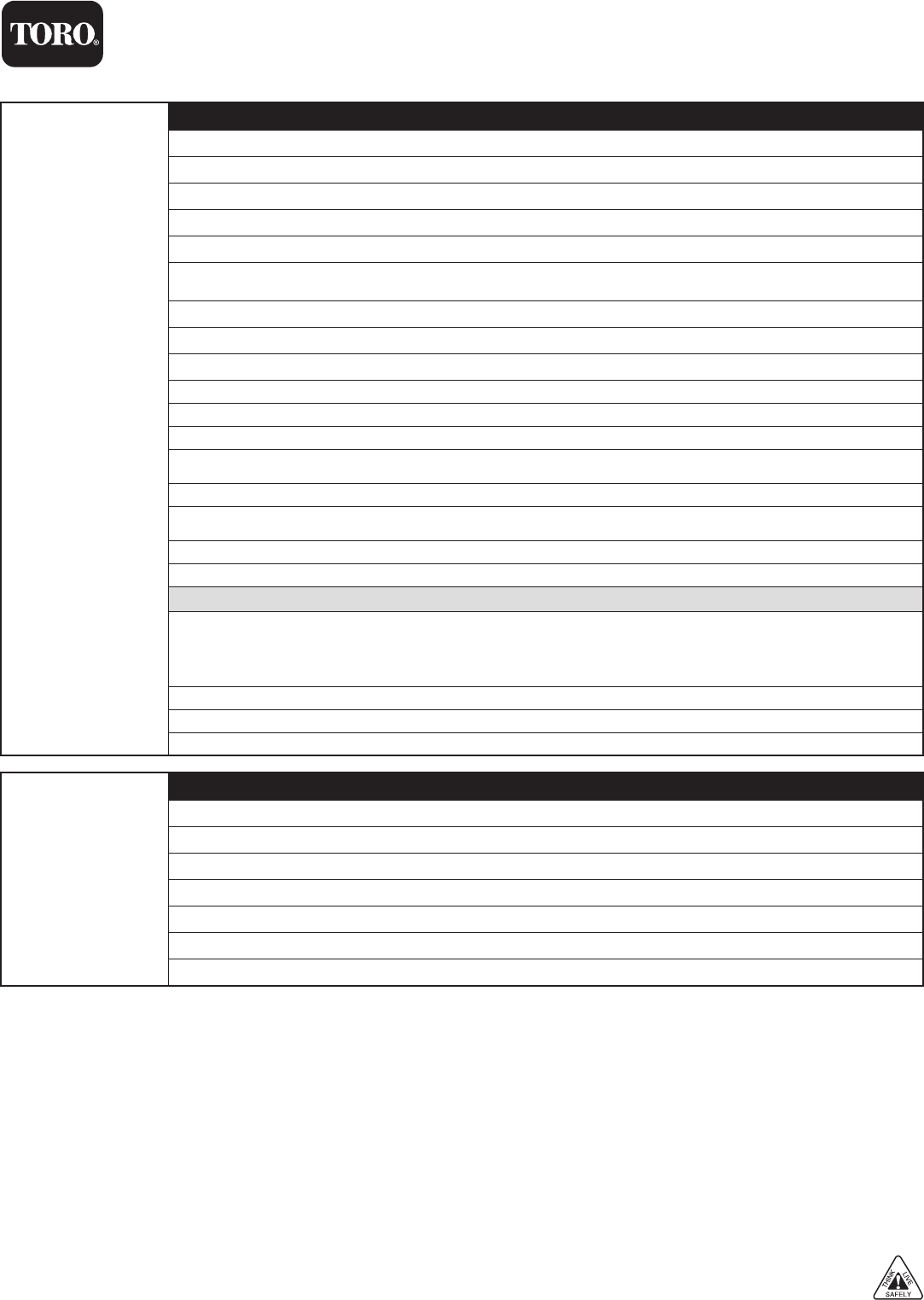

Cutting Units: 27” 8-BLADE, MODEL 03710 27” 11-BLADE, MODEL 03711 32” 8-BLADE, MODEL 03712

TYPE

5-plex, hydraulically driven, with adjustable rear weight transfer spring. Interchangeable to all positions with rear throw capability.

SIZE

7” (17.8 cm) diameter, 27" (68.6 cm) wide, 8 & 11" blade cutting units and 32” (81.3 cm) 8-blade cutting units.

WIDTH OF CUT

121” (307 cm) or 126” (320 cm)

HOC RANGE

0.25" - 2.50" (6.35 - 63.5 mm)

REEL SPEED

Manually controlled, variable reel speed, incrementally adjustable between 200-1,650 rpm with a backlap speed of 200 rpm.

BEDKNIFE ADJUSTMENT

Dual Precision Adjustment (DPA), bedknife to reel.

ROLLERS

3" (7.6 cm) diameter, deep groove plastic front Wiehle roller. 3.0" (7.6 cm) diameter steel rear roller (other roller configurations optional).

Reelmaster

®

7000-D Specifications

*

REELMASTER 7000-D, MODEL 03780

ENGINE

Tier 4 emission compliant Yanmar® 4-cylinder, liquid-cooled diesel engine, 55 hp (41 kW)

LUBRICATION

6-Quarts (5.7 liters)

AIR CLEANER

Dry, replaceable primary and safety elements.

ENGINE COOLING

Rear-mount, aluminum, 6 fins per inch, 9 quart (8.5 liters) capacity.

FUEL TANK CAPACITY

22 gallons (83 liters) diesel fuel. Biodiesel-Ready for use up to B-20 (20% biodiesel and 80% petrol blend).

HYDRAULICS/COOLING

8.25 gallon (31.3 liter) capacity with 10 micron remote spin-on filter, aluminum side-mounted cooler. Variable speed hydraulic fan drive with automatic (based on

coolant and oil temps) and manual reversing capabilities.

MAIN FRAME

All welded formed-steel frame with integral tie-down anchors.

TRACTION DRIVE

Full-time, bi-directional, hydrostatic, closed-loop, 4WD transmission. Optional 4WD Flow Divider Kit, model 30876

GROUND SPEED

Transport: 0-14 mph (0-22.5 km/h) forward, 0-7 mph (0-11 km/h) reverse. Mow: 0-7 mph (0-11 km/h) forward.

TIRES

Front: 31x13.5-15, 4-ply turf tire. Rear: 20 x 12-10, 4-ply multi-trac tread. 12-15 PSI recommended range.

BRAKES

Mechanically actuated, internal wet disc brakes. Individual foot-operated steering brake control of left and right wheel or lock pedals together.

STEERING

Power steering with dedicated power source, tilt steering.

GAUGES/INDICATORS

Onboard LCD InfoCenter display shows alerts, faults, service reminders, electrical systems diagnostics, coolant temp., low oil pressure, alternator, engine hours,

engine rpm, voltage, reel speed, backlap speed, glow indicator, lift/lower indicator.

SEAT

Premium air ride suspension seat with full range of adjustments; retractable seat belt.

CONTROLS

Ignition switch, hand-operated throttle, foot-operated traction pedal, joystick for cutting unit lift, mow/transport selector switch, lockable individual brake pedals,

park brake.

ELECTRICAL & INTERLOCKS

12-volt, 650 CCA battery, 80 amp alternator. Overload protection with automotive type fuses. Interlocks for: starting, operator presence, mowing, transport and parking brake.

DIAGNOSTICS

Diagnostics pressure test ports: forward and reverse traction, cutting unit circuit 1 & 2, lift, steering, traction charge and fan

REEL OPTIONS

DIMENSIONS

WITH CUTTING UNITS

All 27” CUs or 32” in the rear All 32” CUs

Overall length w/cutting units down 146" (371 cm) 146" (371 cm)

Transport width 94" (239 cm) 94" (239 cm)

Mow width 136” (345 cm) 141” (358 cm)

Height w/2-post ROPS 87" (220 cm) 87" (220 cm)

WEIGHT

3,470 lbs. (1574 kg) - with full fluids, no cutting units. 4,270 lbs (1937 kg) - with full fluids and 27” 8-blade cutting units.

SAFETY CERTIFICATION

Complies with American National Standards Institute (ANSI B71.4-2012) and applicable CE (EN ISO 5395) requirements.

WARRANTY

Two-year limited warranty. Refer to the Operator’s Manual for further details.

* Specifications and design subject to change without notice. Products depicted in this literature are for demonstration purposes only.

Actual products offered for sale may vary in use, design, required attachments and safety features. See distributor for details on all warranties.

The Reelmaster 7000-D is manufactured

in Tomah, WI ISO 9002 Certified Plant.