Mfg P/N 98807 Rev 8, Page 11

Before attempting to measure or adjust manifold gas pressure,

the inlet (supply) pressure must be within the specified range for

the gas being used both when the heater is in operation and on

standby. Incorrect inlet pressure could cause excessive manifold

gas pressure immediately or at some future time.

Instructions to Check Manifold Pressure:

1) With the manual valve (on the combination valve) positioned

to prevent flow to the main burners, connect a manometer to

the 1/8" pipe outlet pressure tap in the valve. NOTE: A ma-

nometer (fluid-filled gauge) is recommended rather than a

spring type gauge due to the difficulty of maintaining calibration of a

spring type gauge.

2) Open the valve and operate the heater. Measure the gas pressure to the

manifold. Normally adjustments should not be necessary to the factory

preset regulator.

If adjustment is necessary, set pressure to correct settings by turning the regu-

lator screw IN (clockwise) to increase pressure. Turn regulator screw OUT

(counterclockwise) to decrease pressure.

Consult the valve manufacturer's literature provided with the heater for more

detailed information.

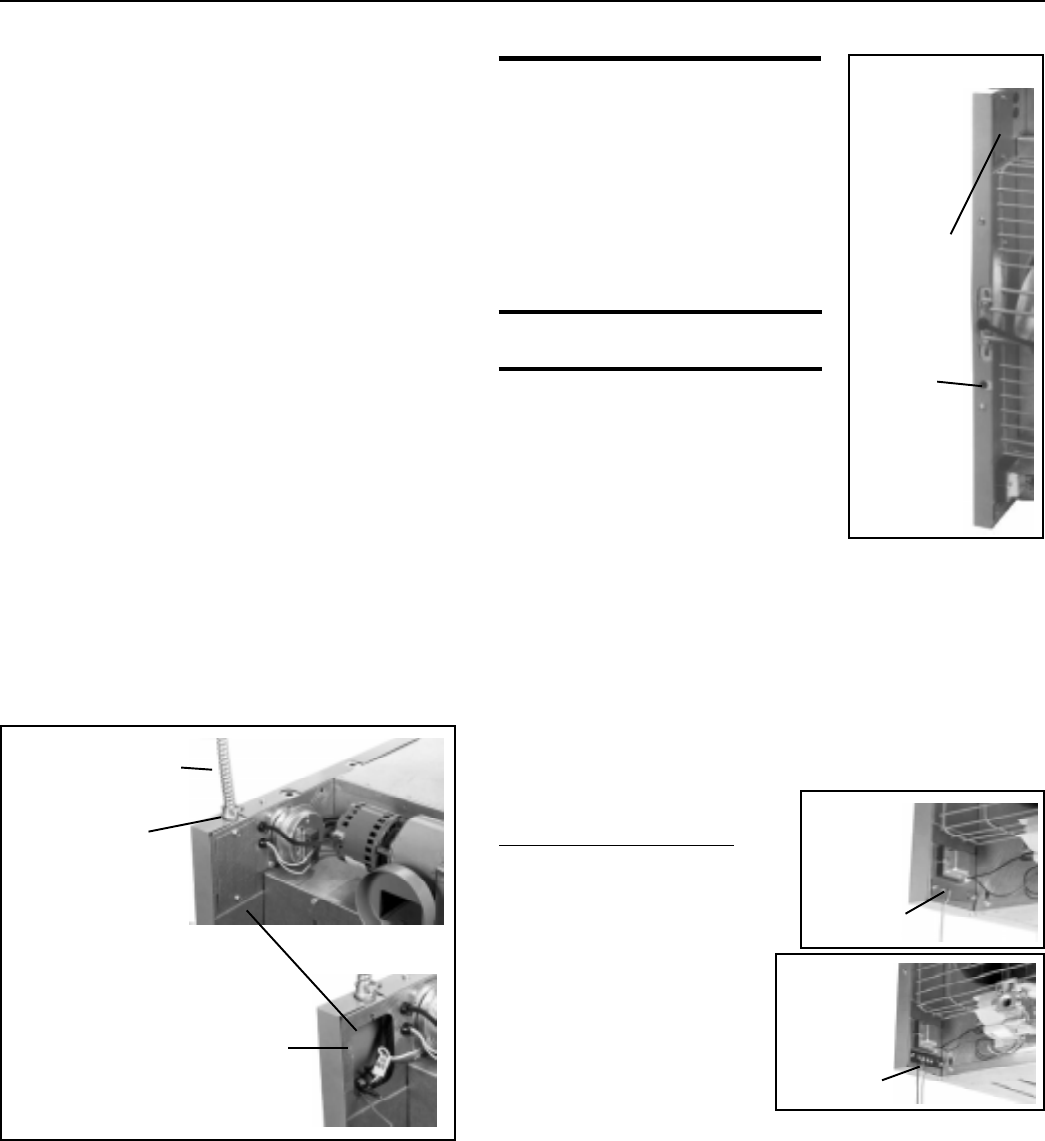

11. Electrical Supply and Connections

All electrical wiring and connections, including electrical ground-

ing MUST be made in accordance with the National Electric

Code ANSI/NFPA No. 70 (latest edition) or, in Canada, the Ca-

nadian Electrical Code, Part I-C.S.A. Standard C22.1. In addi-

tion, the installer should be aware of any local ordinances or gas

company requirements that might apply.

Check the rating plate on the heater for the supply voltage and

current requirements. A separate line voltage supply with fused

disconnect switch should be run directly from the main electri-

cal panel to the heater. All external wiring must be within ap-

proved conduit and have a minimum temperature rise of 60

o

C.

Conduit from the disconnect switch must be run so as not to

interfere with the service panels of the heater.

The electrical supply connects at the top back of the heater in the

left corner (left when facing the back of the heater). A threaded

hole is provided for a standard 1/2" electrical fitting.

The wiring access panel is easily removed for field connections.

Consult the wiring diagram supplied with your heater. Replace

the panel after the wiring connections are made.

If the heater has field-installed options that require electrical con-

nections, consult the instruction sheet and wiring diagram sup-

plied in the option package.

A fan-type heater may be equipped with a built-in fused discon-

nect switch (Option AI-1). If the heater is equipped with a built-

in disconnect switch, a two-position toggle (on/off) switch is

located near the electrical supply access panel (See Figures 9A

and 9B). This switch may be used to disconnect the power when

servicing the heater other than in the supply junction box.

Specific wiring diagrams that include standard and factory-in-

stalled options are included with the heater. Check the wiring

diagram to identify optional equipment.

Figure 10 -

Two Screw

Terminal

Connector

Strip for

24-volt

Wiring

Figure 9A - Electrical

Connections

Remove

Access

Panel to

make

connections

WARNINGS: On a heater with

a unit disconnect switch (Option

AI-1), if the power is turned off

at the switch, the supply lead in

the electrical supply junction

box (Figure 9A) remains

energized. If service is to be

done in the supply junction box,

turn off the power at the remote

disconnect switch.

If you turn off the power supply,

turn off the gas.

The operating sequence of the heater can be

found on the heater wiring diagram and is pub-

lished in Paragraph 24, Check Installation and

Start-Up. Typical wiring diagrams are on the

next four pages, showing standard single-

stage heating with spark pilot with and with-

out lockout.

CAUTION: If any of the original wire as

supplied with the appliance must be replaced, it must be replaced with

wiring material having a temperature rating of at least 105

o

C, except for

limit control and sensor lead wires which must be 150

o

C. See Hazard

Levels, page 2.

12. Thermostat and Thermostat

Connections

A thermostat is not standard equipment but is an installation requirement.

Use either an optional thermostat available with the heater or a field-supplied

thermostat. Install according to the thermostat manufacturer's instructions.

Make sure that the heat anticipator setting on the thermostat is in accordance

with the amperage value noted on the

wiring diagram of your heater.

Terminal Strip Connections - The

standard heater is equipped with a two-

screw terminal connector strip (See Fig-

ure 10) for easy connection to the low

voltage controls (24V). When factory-

installed options require two-stage

thermostat control, the heater is

equipped with a SP-ST relay and a

four-screw terminal connector strip

(See Figure 11).

If your heater requires field instal-

lation of the four-screw terminal

strip and the relay, follow the in-

structions packaged with the relay

or thermostat option.

If equipped

with unit-

mounted

disconnect

switch, on/

off toggle

switch is

near access

panel to

electrical

supply

junction

box.

Circuit

breaker

button for

Option AI-1

unit-

mounted

disconnect

switch

Threaded

Hole for

Standard 1/2"

Fitting

Figure 11 -

Four Screw

Terminal

Connector

Strip for 24-

Volt Wiring

Figure 9B

(Paragraph 12 continued on page 16.)

Field Wiring

from Disconnect

in Conduit

Note: Fan-type

heaters with optional

built-in disconnect

switch, have an on/off

switch located near

the electrical supply

access panel.