ÃÃ CHECK ENGINE AND EQUIPMENT OFTEN FOR LOOSE

NUTS, BOLTS AND ATTACHMENTS AND KEEP THESE

ITEMS TIGHTENED.

MAINTENANCE

WARNING - TEMPERATURE OF MUFFLER AND NEARBY

AREAS MAY EXCEED 150

0

F (65

0

C). AVOID THESE AREAS.

ÀÀ ENGINE OIL LEVEL:

Check oil level every five (5) operating hours or each time

engine is used. See “TO FILL OIL SUMP OR CHECK OIL

LEVEL” on Page 2.

ÁÁ CHANGE OIL:

Change oil after first two (2) operating hours and every 25

operating hours thereafter, more often if operated in extremely

dusty or dirty conditions.

Change oil while engine is still warm from recent running.

A. Clean area around oil drain plug.

B. Position equipment so engine oil drain plug is lowest point

on engine (see Figure 1).

C. Remove oil drain plug and oil fill plug to drain oil.

D. Replace oil drain plug and tighten securely.

E. Fill oil sump with recommended oil. See “OIL & FUEL

RECOMMENDATIONS’’ and “TO FILL OIL SUMP OR

CHECK OIL LEVEL” on Page 2.

F. Replace oil fill plug and tighten securely.

G. Wipe up any spilled oil.

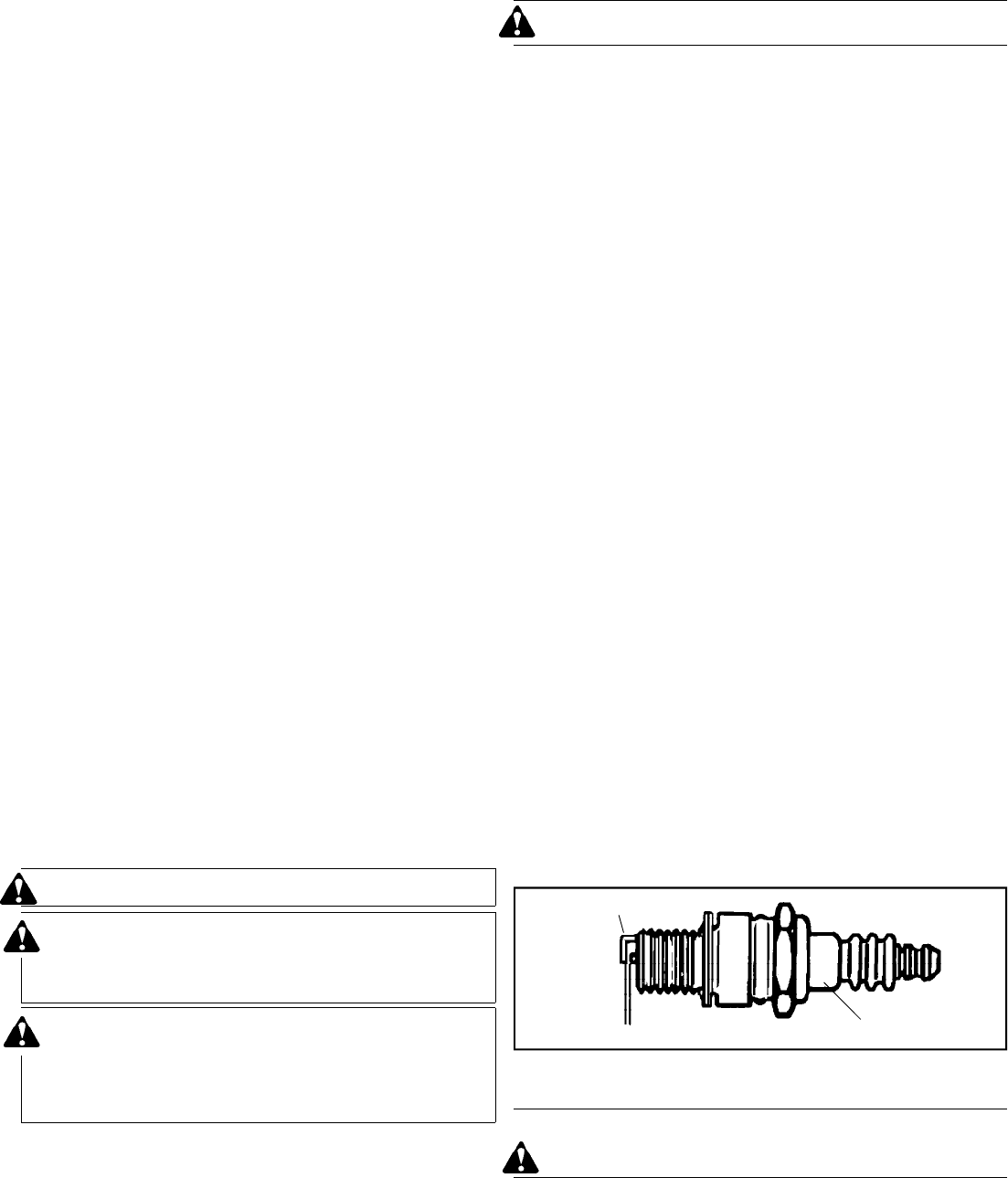

ÂÂ SPARK PLUG (see Figure 6):

This spark ignition system meets all requirements of the

Canadian Interference-Causing Equipment Regulations. This

engine complies with all current Australian and New Zealand

limitation regarding electromagnetic interference.

Check spark plug yearly or every 100 operating hours.

A. Clean area around spark plug base.

B. Remove and inspect spark plug.

C. Replace spark plug if electrodes are pitted, burned or

porcelain is cracked. For replacement use Champion

RJ-19LM or equivalent.

NOTE: A resistor spark plug must be used for replace-

ment.

D. Check electrode gap with wire feeler gauge and set gap at

.030 if necessary.

E. Install spark plug in engine and tighten securely.

Page 4

ELECTRODES

PORCELAIN

.030 GAP

Figure 6

181-637-14

STOPPING

ÀÀ BEFORE STOPPING (see Figure 1):

A. Run engine for a few minutes to help dry off any moisture

on engine.

B. To help avoid possible freeze-up of starter, proceed as

follows:

RECOIL STARTER:

With engine running, pull starter rope with a rapid continu-

ous full arm stroke three or four times.

NOTE: The unusual sound made by pulling starter rope

will not harm engine or starter.

ELECTRIC STARTER:

1. Connect power cord to switchbox, then to wall outlet.

2. With engine running, push starter button and spin starter

for several seconds.

NOTE: The unusual sound made by spinning starter

will not harm engine or starter.

3. Disconnect power cord from receptacle first, and then

from switchbox.

ÁÁ STOP ENGINE (see Figure 1):

A. Move equipment control (see equipment manufacturer’s

instructions), engine control lever or ignition switch (if so

equipped) to “STOP” or “OFF”.

B. Remove ignition key (if so equipped see Figure 2) from

carburetor cover.

DO NOT TURN IGNITION KEY.

ÂÂ AFTER ENGINE IS STOPPED (see Figure 1):

A. To help avoid possible freeze-up of engine controls,

proceed as follows:

1. Wipe all snow and moisture from engine in vicinity of

control lever and choke.

2. Move equipment control (see equipment manufactur-

er’s instructions) or engine control lever back and

forth several times and leave in the “STOP” or “OFF”

position.

3. Move engine choke back and forth several times and

leave in the “FULL” position.

B. Close fuel valve (see Figure 3).

C. DISCONNECT SPARK PLUG WIRE FROM SPARK

PLUG AND KEEP IT AWAY FROM SPARK PLUG.

D. TURN IGNITION SWITCH KEY (IF SO EQUIPPED) TO

“OFF” POSITION AND REMOVE KEY FROM SWITCH.

THIS WILL REDUCE THE POSSIBILITY OF UNAUTHO-

RIZED STARTING OF ENGINE WHILE EQUIPMENT IS

NOT IN USE.

NEVER STORE ENGINE WITH FUEL IN TANK IN-

DOORS OR IN ENCLOSED, POORLY VENTILATED

AREAS, WHERE FUEL FUMES MAY REACH AN OPEN

FLAME, SPARK OR PILOT LIGHT AS ON A FURNACE,

WATER HEATER, CLOTHES DRYER OR OTHER GAS

APPLIANCE.