74

ENGLISH

EN

5.10.3Air filter (Pro Svan)

Clean the air filter every 3 months or after every 50

hours of operation, whichever comes first.

Clean the paper filter insert once a year or after

every 200 hours of operation, whichever comes

first.

Note! Both filters should be cleaned more often if

the machine operates on dusty ground.

1. Remove the protective cover of the air filter

(fig. 28).

2. Dismantle the paper filter insert and the foam

pre-filter. Make sure that no dirt gets into the

carburettor. Clean the air filter housing.

3. Wash the pre-filter in liquid detergent and

water. Squeeze dry. Pour a little oil on the filter

and squeeze in the oil.

4. Clean the paper filter insert as follows: Knock it

lightly against a flat surface. If the filter is very

dirty, change it.

5. Assemble in the reverse order.

Petroleum-based solvents such as kerosene may

not be used for cleaning the paper filter insert.

These solvents can destroy the filter.

Do not use compressed air for cleaning the

paper filter insert. The paper filter insert must

not be oiled.

5.11 Spark plug

The spark plug(s) must be replaced every 200

hours of operation (=at every other basic service).

Use the spark plug key supplied.

Before disconnecting the spark plug, clean around

its mounting.

Spark plug:

Pro16, Pro20, Pro25

: Champion RC12YC or

equivalent.

Pro Svan

: NGK BPR5ES or DENSO W16EPR-U

Electrode distance

: 0.75 mm.

5.12 Air intake

See 9-11:W. The engine is air-cooled. A blocked

cooling system can damage the engine. Clean the

engine’s air intake after 50 hours of operation.

More meticulous cleaning of the cooling system is

carried out during each basic service.

5.13 Lubrication

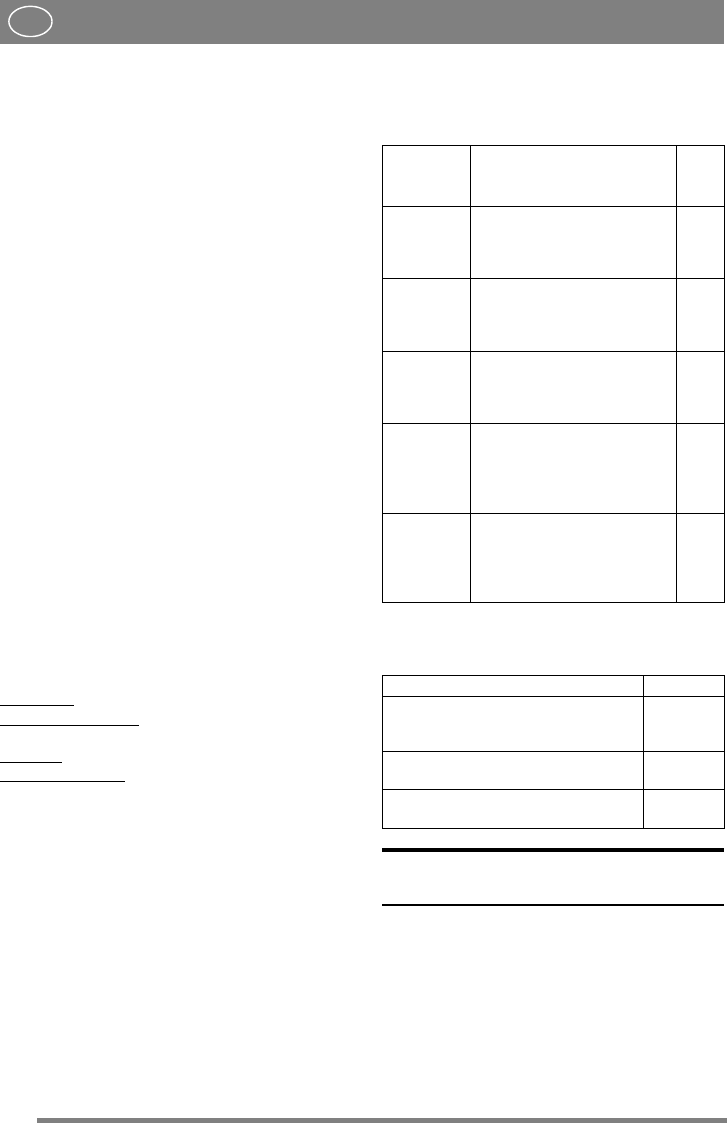

All lubrication points in accordance with the table

below must be lubricated every 50 hours of opera-

tion as well as after every wash.

5.14 Fuses

If any of the faults listed below occurs, replace the

relevant fuse. See fig. 13.

6 PATENT - DESIGN REGISTRA-

TION

This machine or parts thereof is covered by the fol-

lowing patent and design registration:

SE9901091-0, SE9901730-3, SE9401745-6,

US595 7497, FR772384, DE69520215.4,

GB772384, SE0301072-5, SE04/000239 (PCT),

SE0401554-1.

GGP reserves the right to make alterations to the

product without prior notification.

Object Action Fig-

ure

Wheel bear-

ing

2 grease nipples.

Use a grease gun filled with

universal grease. Pump until

the grease emerges.

30

Centre point 4 grease nipples.

Use a grease gun filled with

universal grease. Pump until

the grease emerges.

31

Steering

chains

Brush the chains clean with a

wire brush.

Lubricate with universal

chain spray.

-

Tensioning

arms

Lubricate the bearing points

with an oil can when each

control is activated.

Ideally carried out by two

people.

32

Control

cables

Lubricate the cable ends with

an oil can when each control

is activated.

Must be carried out by two

people.

33

Fault Fuse

The engine does not start or starts and

stops immediately. The battery is

charged.

10 A

Sand spreader and electrical cutting

height adjustment do not work.

20 A

All electrical functions are out of

operation. The battery is charged.

30 A