ENGLISH

GB

COOLING SYSTEM

Before use, the engine's cooling system should be

cleaned. Clean the cylinder's cooling fins and the

air intake, removing any grass cuttings, dirt and the

like.

LUBRICATION

Set at the lowest mowing height. Slacken the

screws and remove the transmission casing (fig. 9).

Lubricate the driveshaft by the plastic bushings/

slide bearings I with oil or oil spray at least once a

season (fig. 11).

CHANGING OIL

Replace the oil when the engine is warm

and the fuel tank is empty. Take care

while draining as the oil is hot, this is to

prevent burns.

Change the oil the first time after 5 hours of

operation, and subsequently after every 50 hours

of operation or once a season. Remove the oil

dipstick and allow the oil to run out into a vessel.

Be careful not to let any oil run on to the grass.

Fill with new oil: use oil of SAE 30 or SAE 10W-

30 quality. The crankcase holds approx. 0.6 litre.

Fill until the oil reaches the “FULL/MAX” mark

on the dip stick.

AIR FILTER

A dirty and blocked air filter reduces the engine

output and increases engine wear.

Clean the filter every three months or after every

25 hours of use, which ever occurs first. More

often if the lawn mower is used on dusty ground.

Briggs & Stratton LS45: Carefully remove the air

cleaner so that no dirt falls down into the

carburettor (fig. 12). Take out the foam plastic

filter element and wash it in liquid detergent and

water. Dry the filter element. Pour a little oil on the

filter element and squeeze it in. Refit the air

cleaner.

Briggs & Stratton XTE 60: Loosen the screw and

fold down the cover of the air cleaner. Carefully

remove the filter cartridge (fig. 13). Knock it

against a flat surface. Replace the filter cartridge

with a new one if it is still dirty.

SPARKING PLUG

Never remove the spark plug or the

ignition lead when checking to see if

there is any spark, always use an

approved test instrument.

Clean the sparking plug regularly (every 100 hours

running). Use a wire brush for cleaning and adjust

the correct spark gap 0.7-0.8 mm (fig. 14).

Change the sparking plug if the electrodes are

excessively burnt or if the plug is damaged. The

recommendations of the engine manufacturers are

as follows:

Champion J19LM (RJ19LM) or another

equivalent spark plug ought to be used in Briggs &

Stratton engines.

ADJUSTMENT OF THE CLUTCH WIRE

If the drive cannot be engaged or disengaged, it

may be that the clutch wire needs adjusting.

Adjust as follows:

1. Remove the transmission cover by unscrewing

the screws S (fig. 9).

2. When the clutch loop is released it should be

possible to roll the mower without any

resistance. If this is not the case, loosen the

locking nut U and screw in the nipple T until the

mower can be moved backwards (fig. 15).

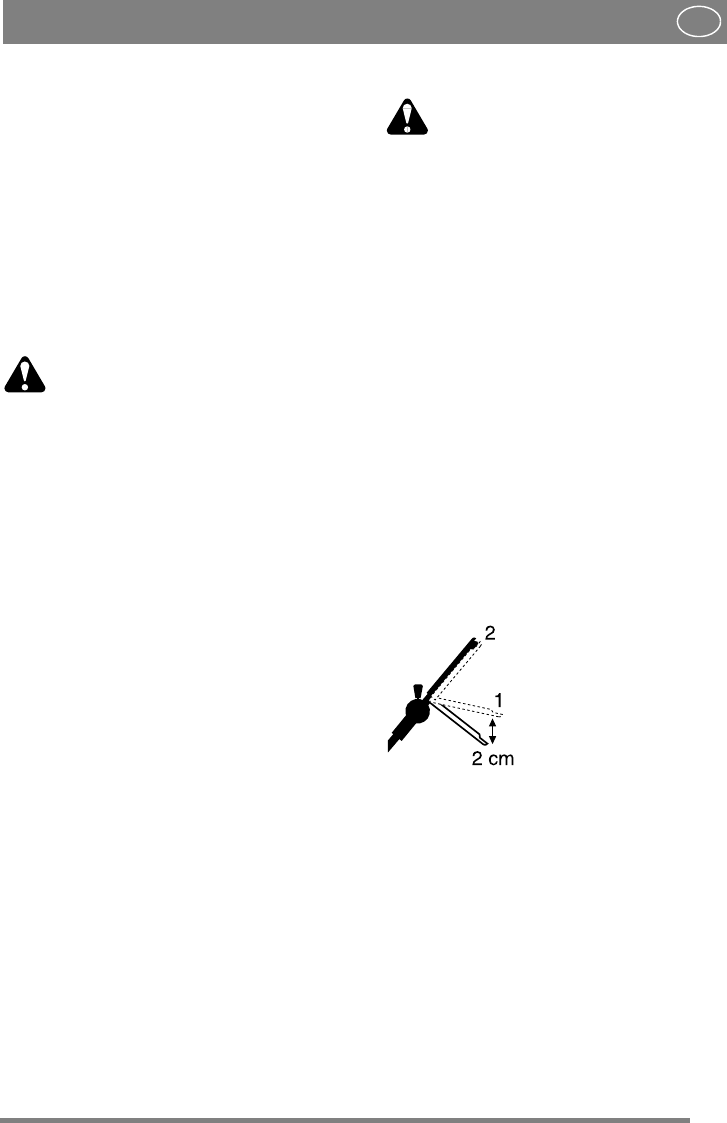

3. When the clutch loop is

pressed in approx. 2 cm

(position 1) there should be

some resistance when moving

the mower backwards. With

the clutch loop fully pressed

in (position 2) it should not be

possible to pull the mower

backwards. Loosen the

locking nut U and screw out

the nipple T until this position

is achieved.

4. Finally tighten the locking nut U.